Method, system and equipment for catalytic coal gasification

A technology of coal catalytic gasification and gasification equipment, which is applied in the directions of joint combustion mitigation and combination of fuel pre-dry distillation, etc., can solve the problem that gasification equipment cannot continuously discharge slag and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

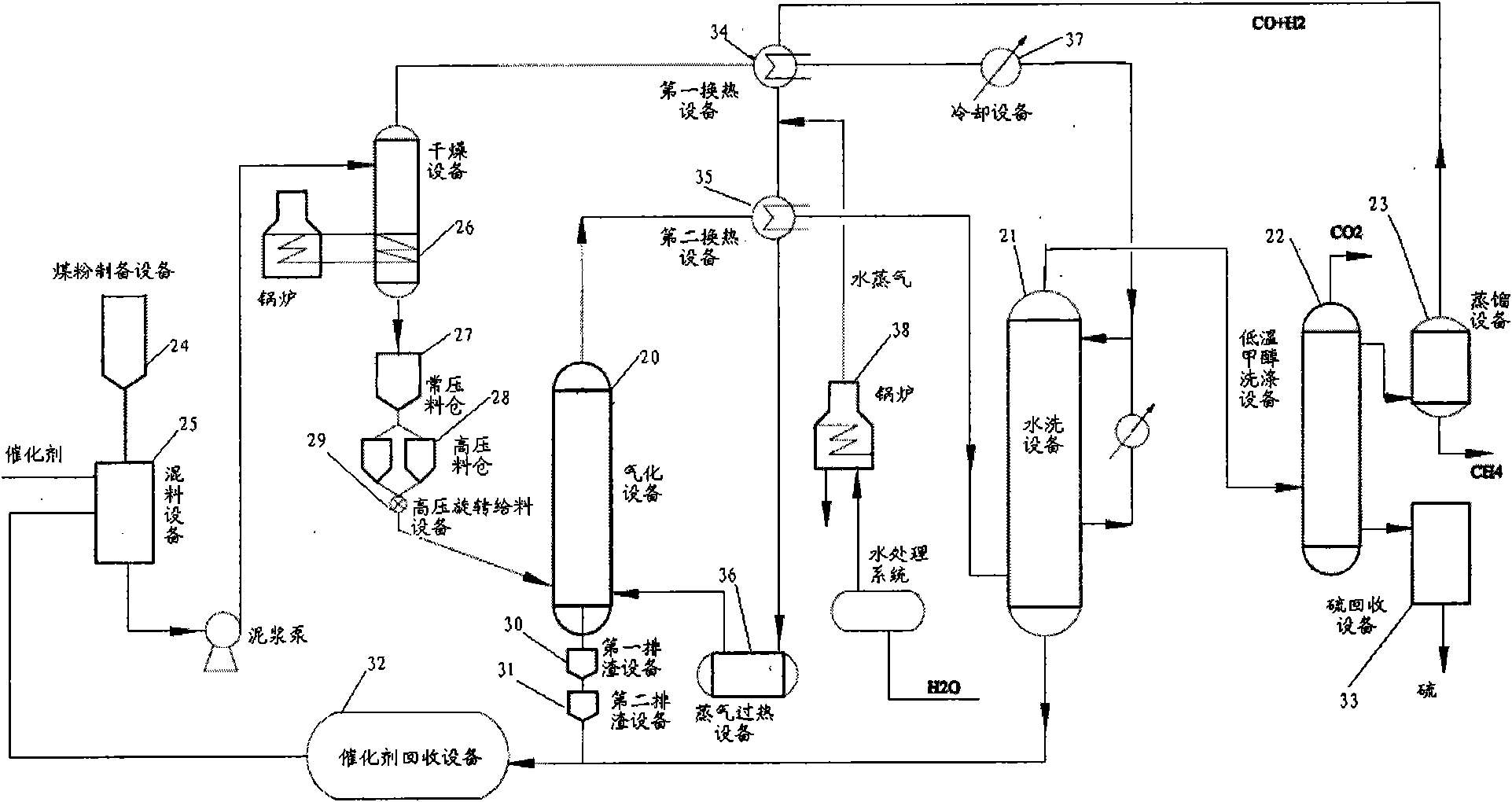

[0025] In order to enable continuous slagging during coal catalytic gasification, the embodiment of the present invention provides a system for coal catalytic gasification. In this system, coal is gasified with a gasification agent under the action of a catalyst in the gasification equipment. Reaction, the gas-solid separation is carried out on the material after the gasification reaction, the solid after gas-solid separation is sent to the slagging system composed of two-stage slagging equipment, and the gas after gas-solid separation is sent to the washing equipment for washing, washing with water The equipment sends the washed purified gas to the low-temperature methanol washing equipment. The low-temperature methanol washing equipment washes the purified gas with low-temperature methanol, and sends the washed mixed gas of methane, hydrogen and carbon monoxide to the distillation equipment, and the distillation equipment then uses the mixed gas Low-temperature distillation i...

Embodiment 2

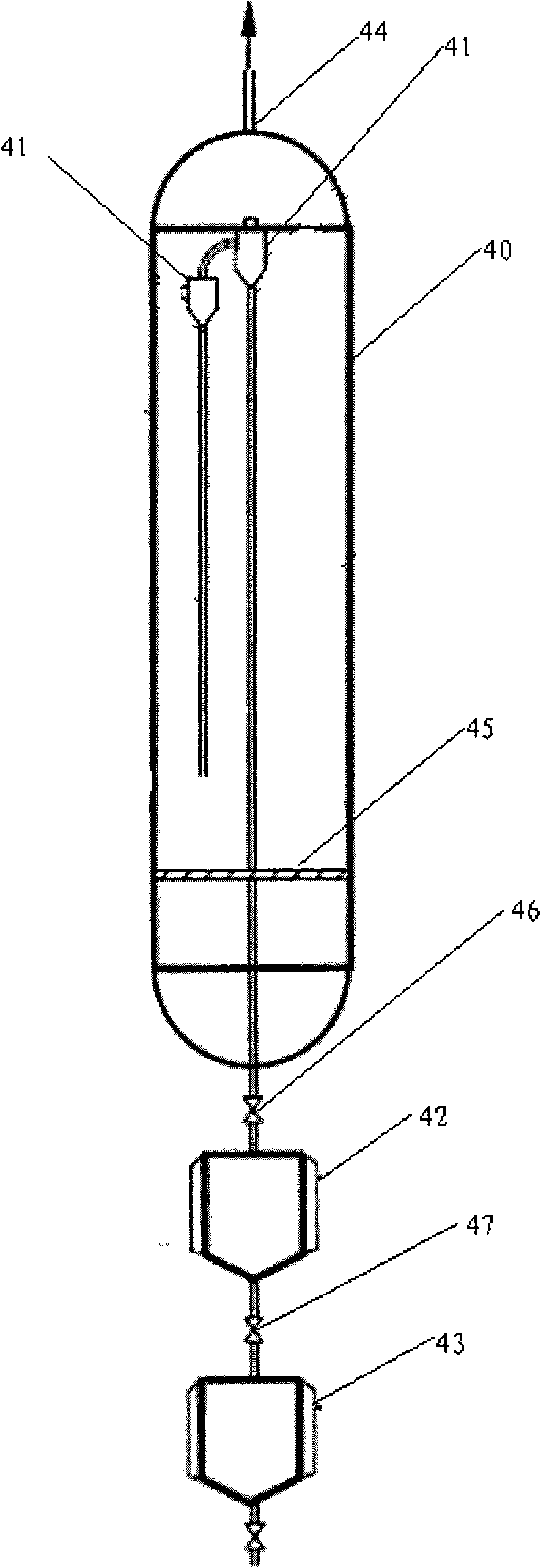

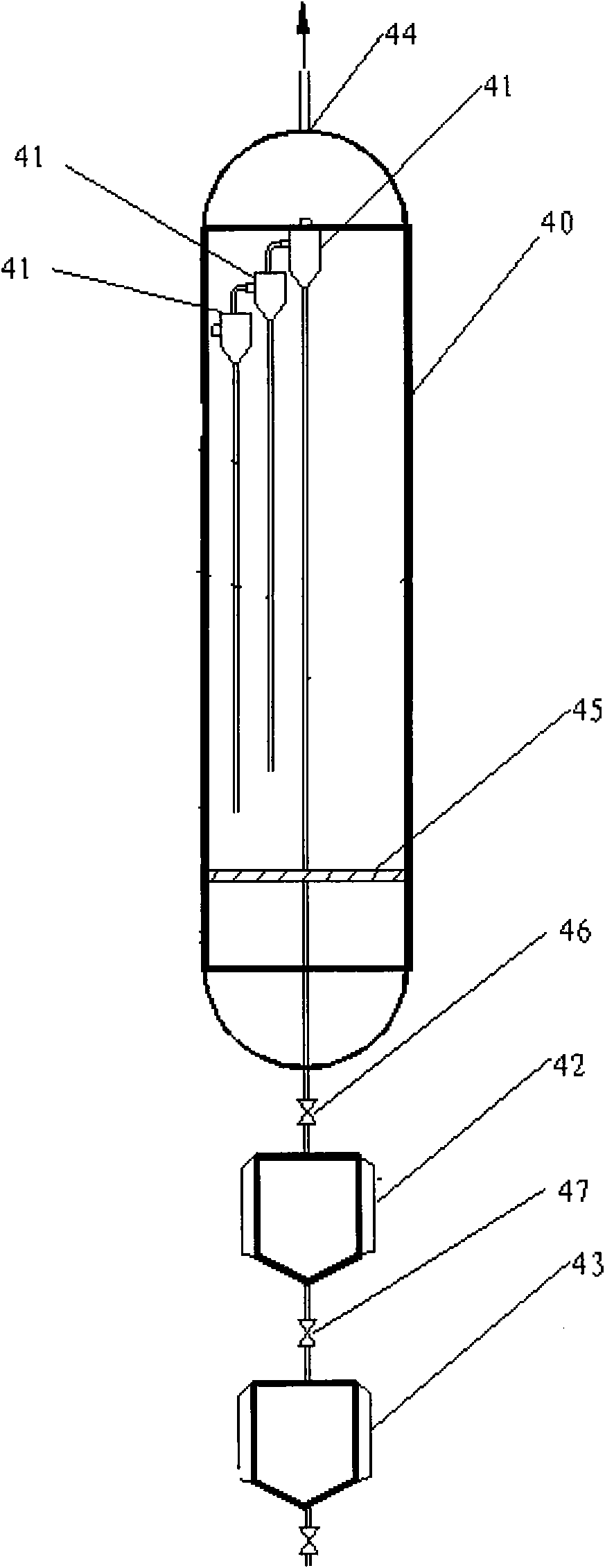

[0048] see figure 2 , the embodiment of the present invention also provides a gasification device, which can be applied to a coal catalytic gasification reaction system, and the device includes:

[0049] The reaction unit 40 is connected with the gas-solid separation unit 41 and is used for gasification reaction of coal and gasification agent under the action of catalyst.

[0050] The gas-solid separation unit 41 is connected with the reaction unit 40 and the first slagging unit 42, and is used for separating the gas-solid material from the gasification reaction, sending the gas-solid separation gas into the water washing equipment, and removing the gas-solid material from the gas-solid separation unit. The separated solids are sent to the first slagging unit 42 .

[0051] The first slag discharge unit 42 is connected to the gas-solid separation unit 41 and the second slag discharge unit 43, and a control gas-solid separation unit 41 and the first slag discharge unit are arr...

Embodiment 3

[0060] The coal required for the gasification reaction in the embodiment of the present invention can be bituminous coal or lignite, etc., and the following table is the material of various product gases and total product gases produced after the gasification reaction is carried out using the system and equipment provided by the embodiment of the present invention Quantity ratio:

[0061] coal type

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com