Direct-fired half-gasification downdraft type full-gasification multifunctional straw furnace

A semi-gasification, multi-functional technology, applied in the fields of heating equipment and cooking, can solve the problems of difficult tar treatment and excessive exhaust gas emissions, and achieve the effects of improving purity, high promotion value and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

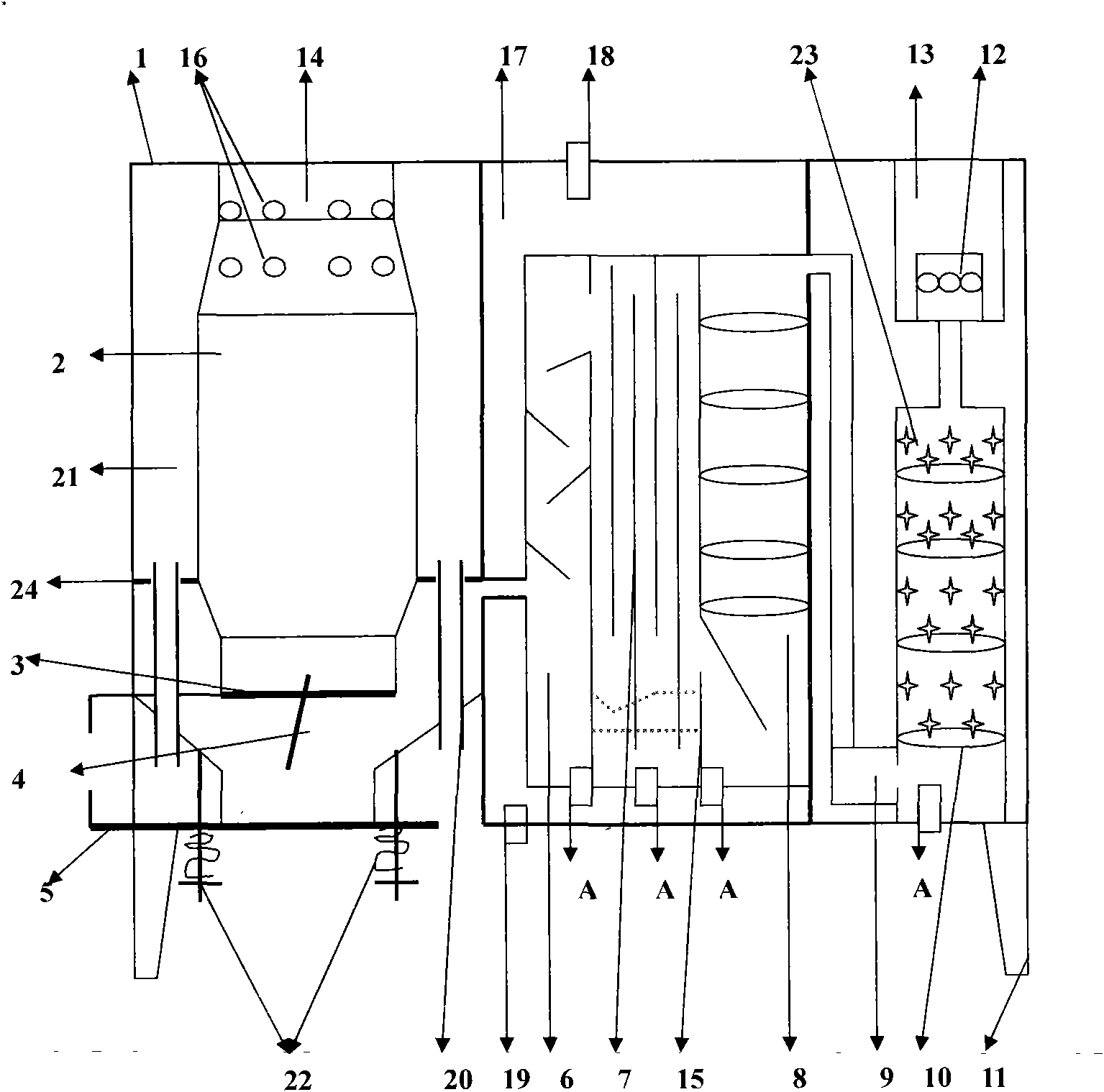

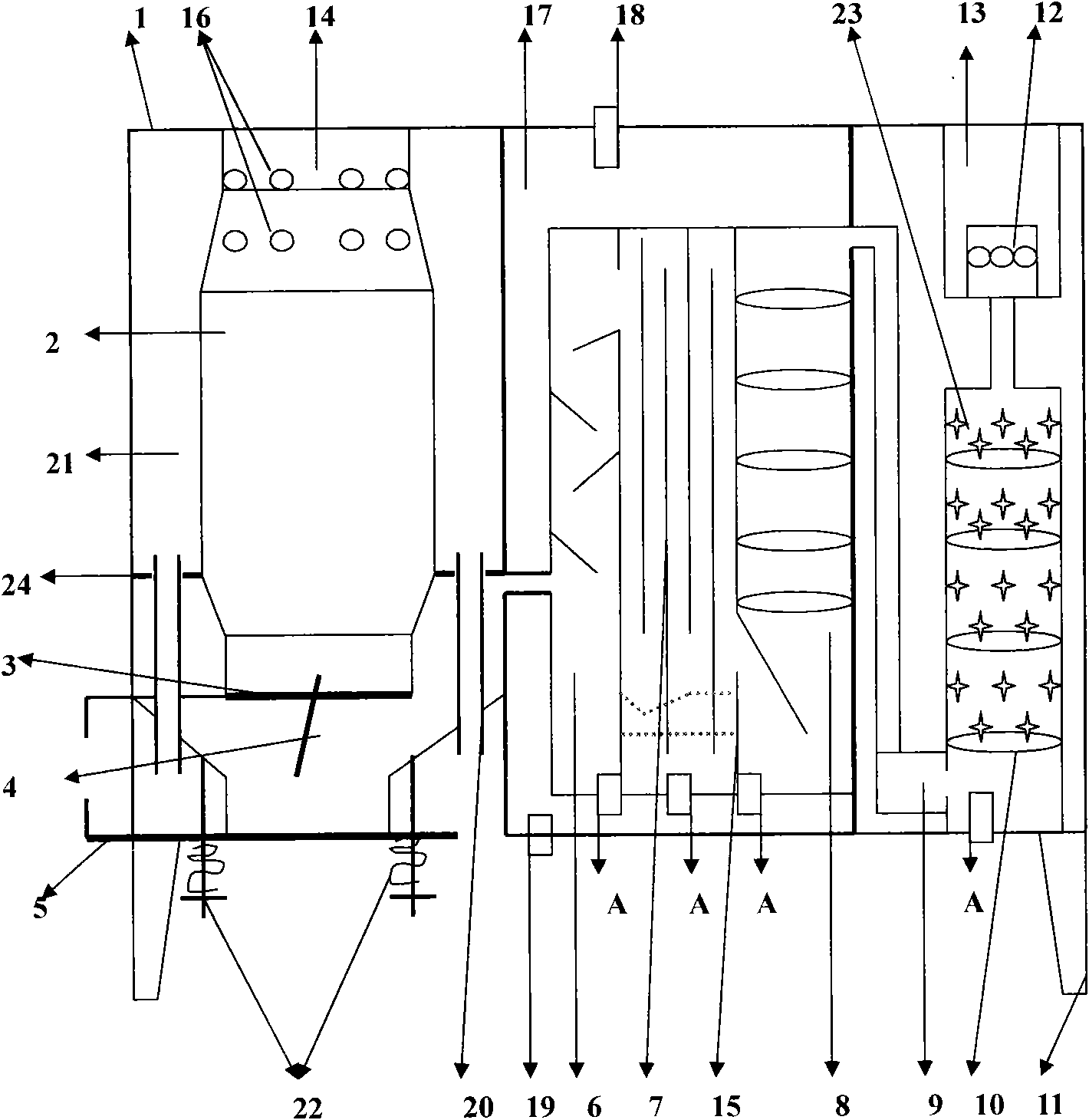

[0016] As shown in the figure: the embodiment feature of this gasifier is: this furnace is a box-type furnace body (1) formed by welding steel plates, and four furnace legs (11) are equipped with four furnace legs (11) to support the furnace body in the bottom of the furnace body. A furnace (2) is installed on the left side of the furnace body, an air inlet sealing plate (24) is installed on the outer lower part of the furnace, an air inlet pipe (20) is welded on the sealing plate of the air inlet chamber, and a fire grate is installed on the lower part of the furnace The bottom of the furnace grate is equipped with a dust removal handle (4), and the bottom is equipped with a dust removal pull plate, which can realize two times of dust removal. A water tank (17) is welded on the right side of the furnace. , the top of water tank is provided with water inlet (18), and the bottom is provided with water outlet (19), and the top of furnace hearth is charging port combustion hole (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com