Method for producing hydrogen by converting municipal solid waste

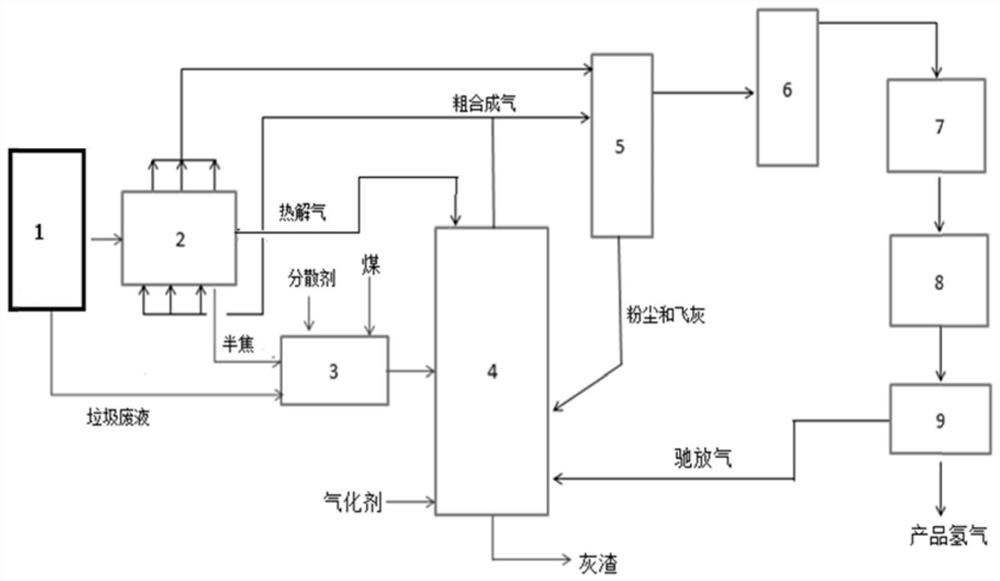

A technology for municipal solid waste and hydrogen production, which is applied in gasification process, granular/powder fuel gasification, petroleum industry, etc., can solve the problems of clogging of multi-functional nozzles, difficulty in direct crushing of waste, and high operating costs, so as to reduce waste and reduce waste. The effect of reducing the cost of liquid treatment, avoiding the risk of secondary pollution, and improving the gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] According to a preferred embodiment, the purification treatment includes:

[0052] S1: Dedusting the crude synthesis gas to obtain dedusted gas, dust and fly ash;

[0053] S2: Purify and deacidify the dedusted gas to obtain synthesis gas;

[0054] S3: returning the dust and fly ash to the gasifier for high-temperature slag treatment.

[0055] In step (5), the present invention has no special limitation on the conversion reaction, and it can be carried out with reference to the coal-water slurry gasification hydrogen production technology, and the specific operation is well known in the art, and will not be repeated here.

[0056] According to the method of the present invention, in order to separate and obtain high-purity product hydrogen, preferably the method further includes: (6) drying and separating the product obtained in step (5) to obtain product hydrogen and purge gas, the purge gas Return to the gasifier for gasification reaction.

[0057] The method of the...

Embodiment 1

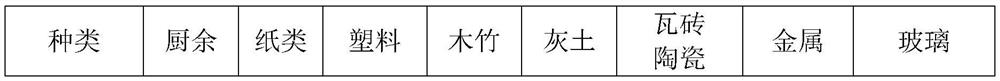

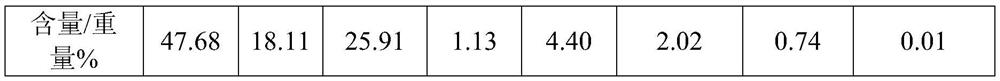

[0085] (1) Municipal solid waste is sorted and crushed, and after removing non-combustible materials such as glass and metal, it is placed in municipal waste storage bin 1 for 4 days, and the moisture in the waste is drained, so that the total moisture content of the waste is reduced to 43% by weight , and use the leached waste liquid as subsequent pulping water;

[0086] (2) The waste material enters the pyrolysis reactor 2, is dried under the indirect heating of the crude synthesis gas from the gasifier 4, and undergoes a pyrolysis reaction to obtain waste semi-coke and pyrolysis gas. The final heat in the reactor is The solution temperature is 450°C, and the residence time of garbage raw materials is 40 minutes;

[0087] (3) Grinding and stirring garbage semi-coke, garbage waste liquid, coal powder, and sodium methylene bis-naphthalene sulfonate according to mass percentages of 40%, 38.5%, 20% and 1.5%, to make coal-water slurry;

[0088] (4) Coal water slurry and pyrolysi...

Embodiment 2

[0093] (1) process municipal solid waste according to the method of embodiment 1, obtain garbage raw material and garbage waste liquid;

[0094] (2) The waste material enters the pyrolysis reactor 2, is dried under the indirect heating of the crude synthesis gas from the gasifier 4, and undergoes a pyrolysis reaction to obtain waste semi-coke and pyrolysis gas. The final heat in the reactor is The solution temperature is 550°C, and the residence time of garbage raw materials is 60 minutes;

[0095] (3) Grinding and stirring garbage semi-coke, garbage waste liquid, coal powder, and sodium methylene bis-naphthalene sulfonate according to mass percentages of 44%, 39.5%, 15% and 1.5%, to make coal-water slurry;

[0096] (4) Coal water slurry and pyrolysis gas enter the gasifier 4, and carry out gasification reaction and cracking reaction under the action of oxygen to obtain crude synthesis gas, and control the oxygen-carbon ratio to 0.95m 3 / kg, the gasification pressure is 5MPa;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com