Method for producing hydrogen by converting urban garbage

A technology for the production of hydrogen and municipal waste, applied in chemical instruments and methods, biochemical equipment and methods, gas production bioreactors, etc. To achieve the effect of preventing the formation of dioxins, achieving harmlessness, and avoiding the risk of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

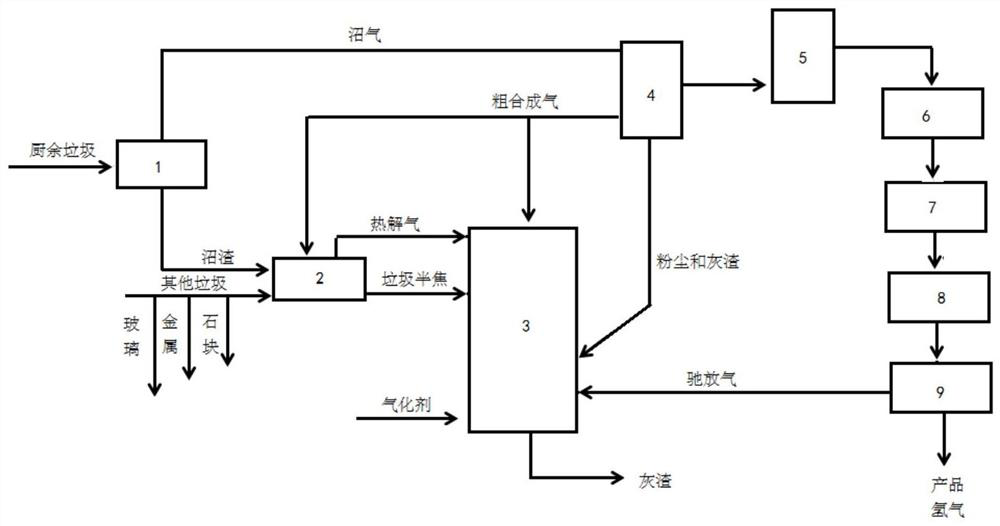

[0034] Such as figure 1 As shown in a specific embodiment provided by the present invention, the first aspect of the present invention provides a method for converting municipal waste into hydrogen, the method comprising:

[0035] (1) Anaerobic fermentation of kitchen waste to obtain biogas residue and biogas;

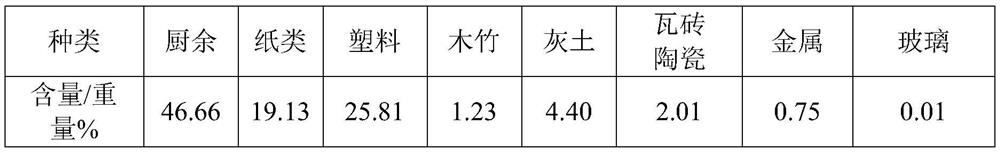

[0036] (2) Dry and pyrolyze other garbage with the biogas residue after pre-sorting to obtain garbage semi-coke and pyrolysis gas; the temperature of the pyrolysis reaction is 350-650°C, and the pyrolysis time 20-120min;

[0037] (3) Carrying out the gasification reaction of the garbage semi-coke and pyrolysis gas to obtain crude synthesis gas and ash;

[0038] (4) returning a part of the crude synthesis gas to step (2) as a heat source for the drying and pyrolysis reactions; mixing the biogas with the remaining part of the crude synthesis gas, followed by purification, steam regenerating Rectification and conversion reaction, get rich in H 2 product gas.

[0039]...

Embodiment approach

[0056] According to a preferred embodiment, the purification treatment includes:

[0057] S1: Dedusting the crude synthesis gas to obtain dedusted gas, dust and fly ash;

[0058] S2: Purify and deacidify the dedusted gas to obtain synthesis gas;

[0059] S3: returning the dust and fly ash to the gasifier for high-temperature slag treatment.

[0060] In step (4), the present invention has no special limitation on the steam reforming and shift reaction, and can refer to the existing gasification hydrogen production technology. The specific operation is well known in the art and will not be repeated here.

[0061] According to a preferred embodiment of the present invention, in order to obtain relatively high-purity product hydrogen for separation, preferably the method further includes (5) drying and separating the product obtained in step (4) to obtain product hydrogen and purge gas. The released gas is returned to the gasifier for gasification reaction.

[0062] The method ...

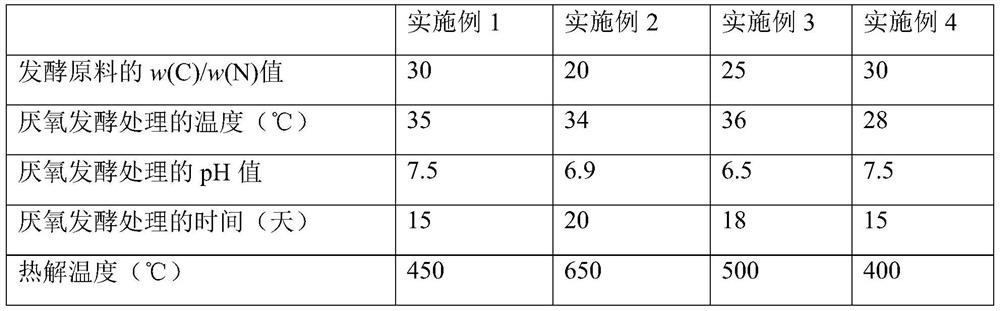

Embodiment 1

[0088] (1) After the kitchen waste is pretreated, a fermentation raw material with a w(C) / w(N) value of 30 is obtained, which is sent to an organic biochemical treatment workshop for anaerobic fermentation treatment, and 25% by weight of Anaerobic sludge with a large amount of methanogens, the anaerobic fermentation temperature is controlled at 35°C, the pH value is 7.5, and the anaerobic fermentation treatment time is 15 days to obtain biogas and biogas residue;

[0089] (2) Other garbage is sorted to remove incombustibles such as glass, metal, stones, etc., and then enters the pyrolysis reactor with biogas residue, and is dried and heated under the indirect heating of part of the crude synthesis gas from the gasifier. Decomposition reaction to obtain garbage semi-coke and pyrolysis gas, the pyrolysis temperature in the reactor is 450 ° C, and the pyrolysis time is 80 minutes;

[0090] (3) Garbage semi-coke and pyrolysis gas enter the gasifier, and undergo gasification reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com