Biomass vaporizing combustion coupled type cyclone boiler

A coupled biomass technology, which is applied to combustion equipment, combined combustion mitigation, and solid fuel combustion, can solve problems such as easy slagging, low thermal efficiency, and high tar content, and achieve improved conversion efficiency, stable operation, and reduced coal consumption. The effect of the possibility of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

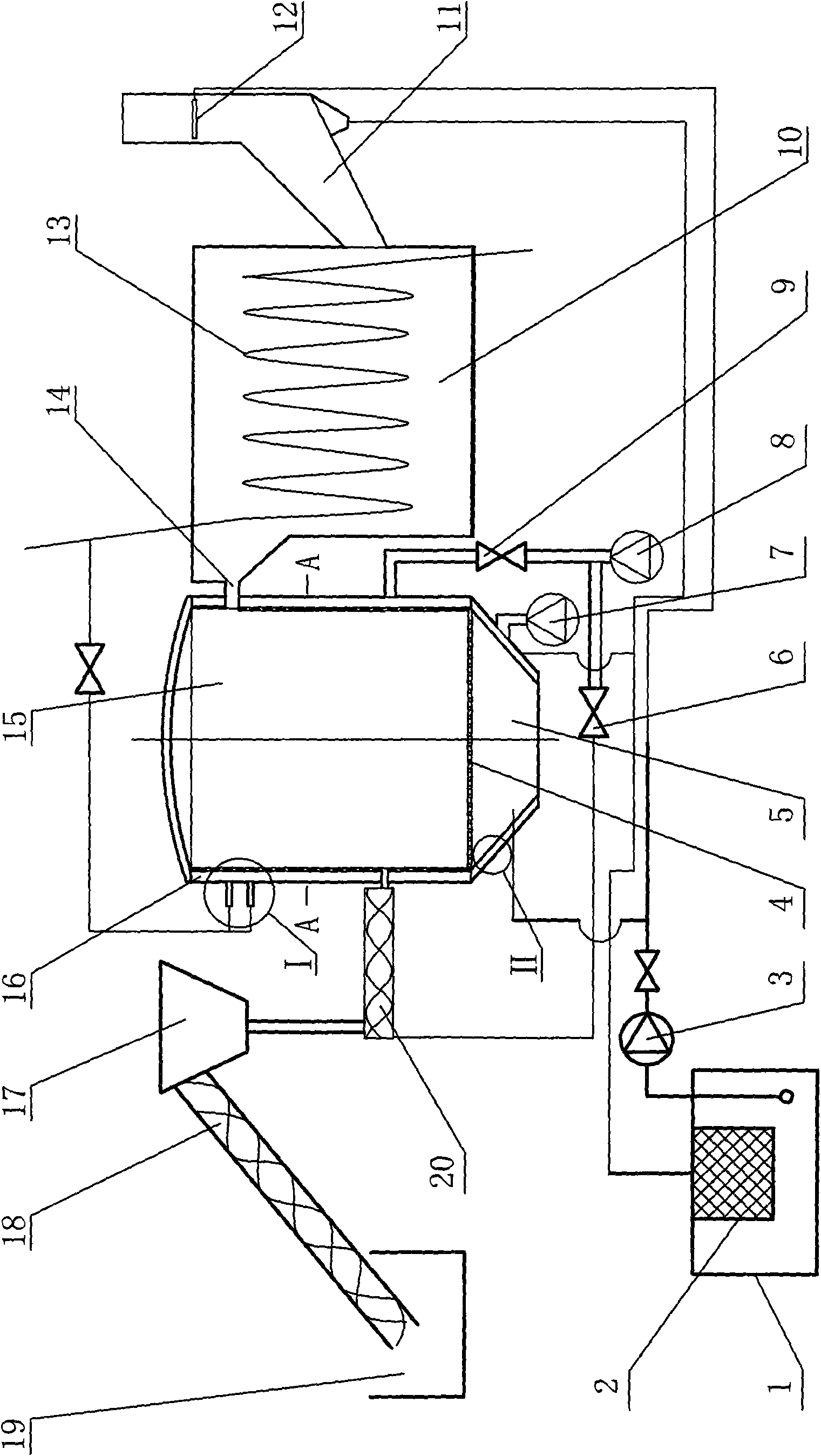

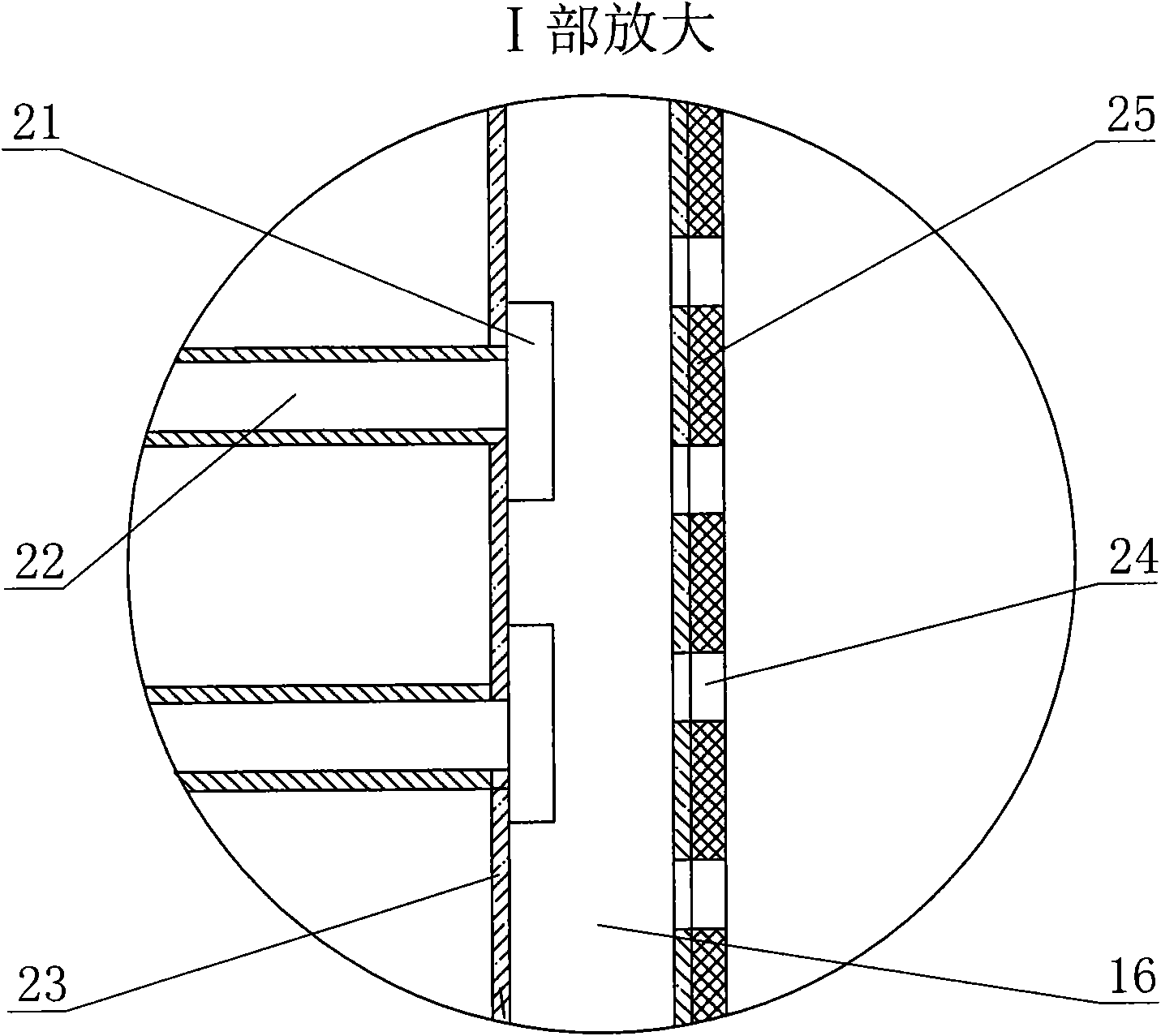

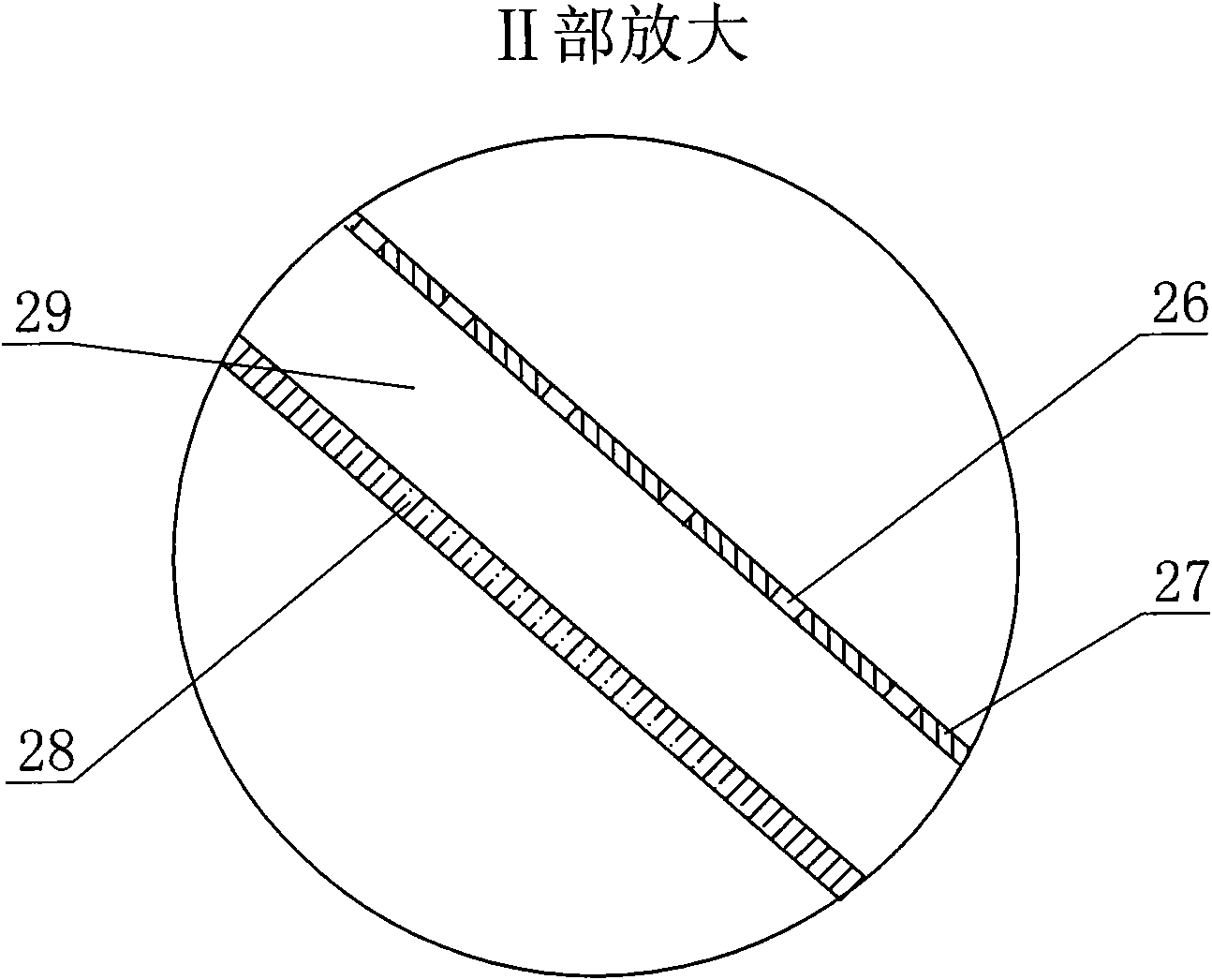

[0018] according to Figure 1~5 The specific structure of the present invention will be described in detail. The biomass gasification combustion coupled cyclone boiler includes a jacketed furnace body with an ash chamber 5, a fire grate 4 and a gasification combustion chamber 15 and a complete combustion chamber 10 with a built-in heat exchanger 13 connected by a connecting pipe 14 The furnace body jacket 16 composed of the inner furnace wall 25 and the outer furnace wall 23 of the common structure of the boiler and the atomizing nozzle 21 communicated with the water inlet pipe 22 arranged inside the outer furnace wall 23, and the inner furnace wall 25 and the gas outlet The steam atomization device formed by the secondary air connected to the chemical combustion chamber 15 and the water vapor tangential spray hole 24 is composed of a raw material bin 19, a large screw feeder 18, a hopper 17 and a small screw feeder 20 arranged below it. The feeding device composed of the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com