System and method for comprehensively recycling for household refuse pyrolysis

A domestic waste and comprehensive treatment technology, which is applied in the field of domestic waste pyrolysis resource comprehensive treatment system, can solve the problems of poor economic benefit, poor economic benefit, and difficult industrialization promotion of domestic waste pyrolysis technology, so as to improve the efficiency of resource utilization and economy, reduce operating costs, and fully recycle the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

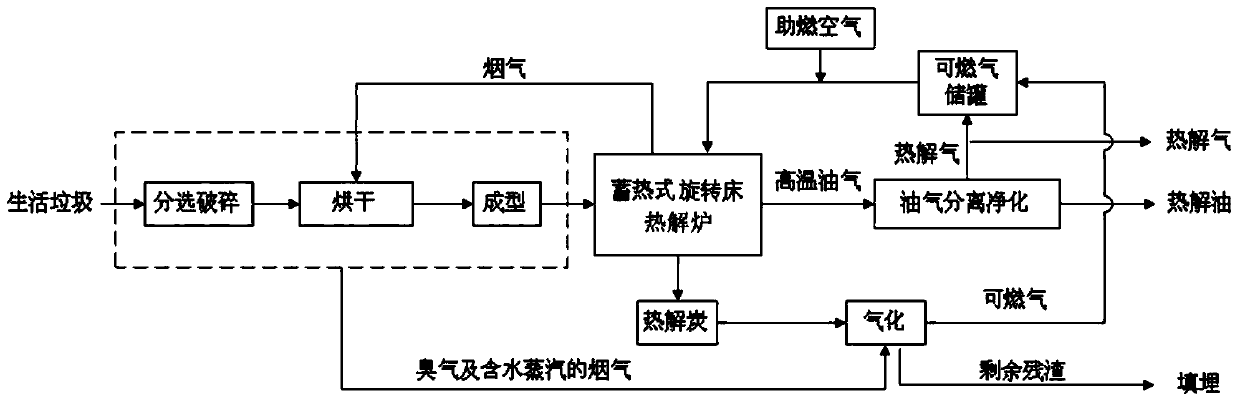

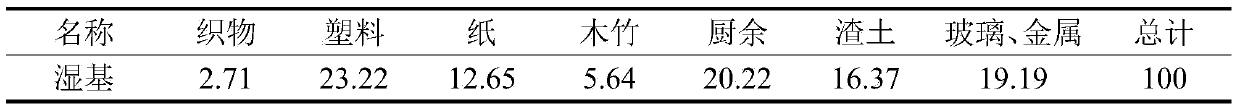

[0061] Using a city's domestic waste as raw material, the water content of the waste is 54%, and its composition is shown in Table 1:

[0062] Table 1 Composition of domestic waste (wt%)

[0063]

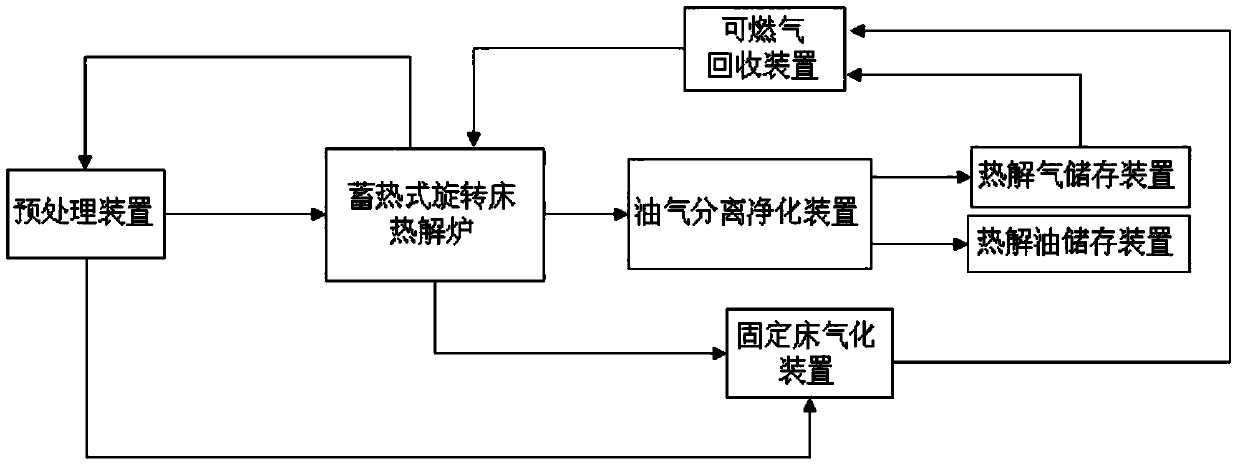

[0064] The waste entering the factory is firstly pretreated, and the pretreatment includes:

[0065] (1) Sorting of domestic waste: mainly adopt drum sieve, air separation, magnetic separation and other methods to separate large pieces of inorganic matter, glass, metal and other substances in the waste;

[0066] (2) Household waste crushing: the sorted waste is crushed into small pieces with a particle size of 30mm-40mm through a two-stage crushing device;

[0067] (3) Drying of domestic garbage: The drying temperature is 180°C, the heat source is flue gas after radiant tube combustion, and the moisture content of the dried garbage is 13%.

[0068] (4) Forming of domestic waste: the dried domestic waste is compressed and formed into rods by waste forming equipment. The diameter...

Embodiment 2

[0075] Using domestic waste from a certain city as raw material, the water content of the waste is 51%, and its composition is shown in Table 2:

[0076] Table 2 Composition of domestic waste (wt%)

[0077]

[0078] The waste entering the factory is firstly pretreated, and the pretreatment includes:

[0079] (1) Sorting of domestic waste: mainly adopt drum sieve, air separation, magnetic separation and other methods to separate large pieces of inorganic matter, glass, metal and other substances in the waste;

[0080] (2) Household garbage crushing: through the two-stage crushing device, the sorted garbage is crushed into small pieces with a particle size of 20mm-35mm;

[0081] (3) Drying of domestic garbage: The drying temperature is 170°C, the heat source is flue gas after radiant tube combustion, and the moisture content of the dried garbage is 15%.

[0082] (4) Forming of domestic waste: the dried domestic waste is compressed into a cake shape by the waste forming equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com