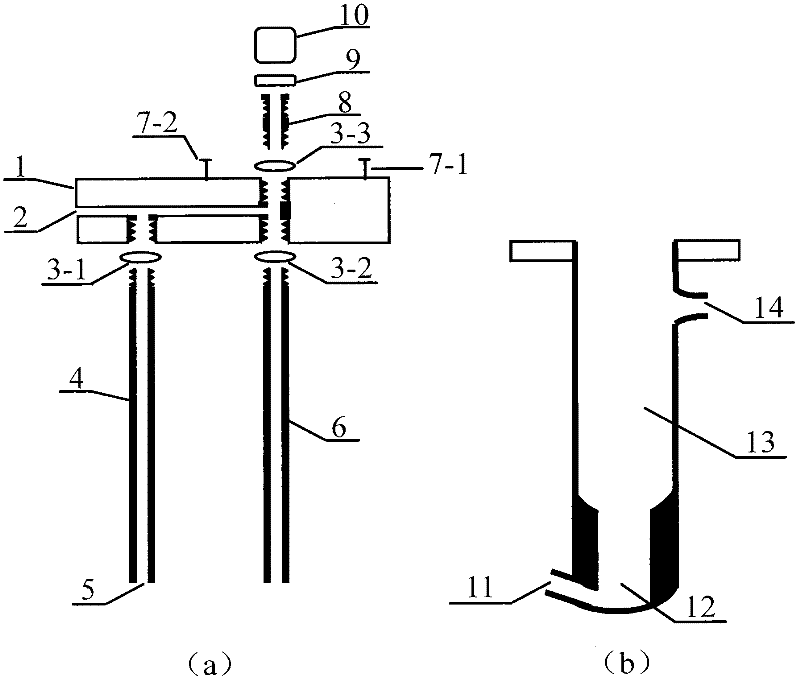

Liquid organic atomization and gasification device

A technology of gasification device and organic matter, which is applied in the direction of measuring device, chemical/physical/physical chemical process, chemical instrument and method, etc., can solve the problems of long stable time and inaccurate concentration of gas distribution device, and achieve large-scale inaccurate Intermittent operation, accurate results, and the effect of improving gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

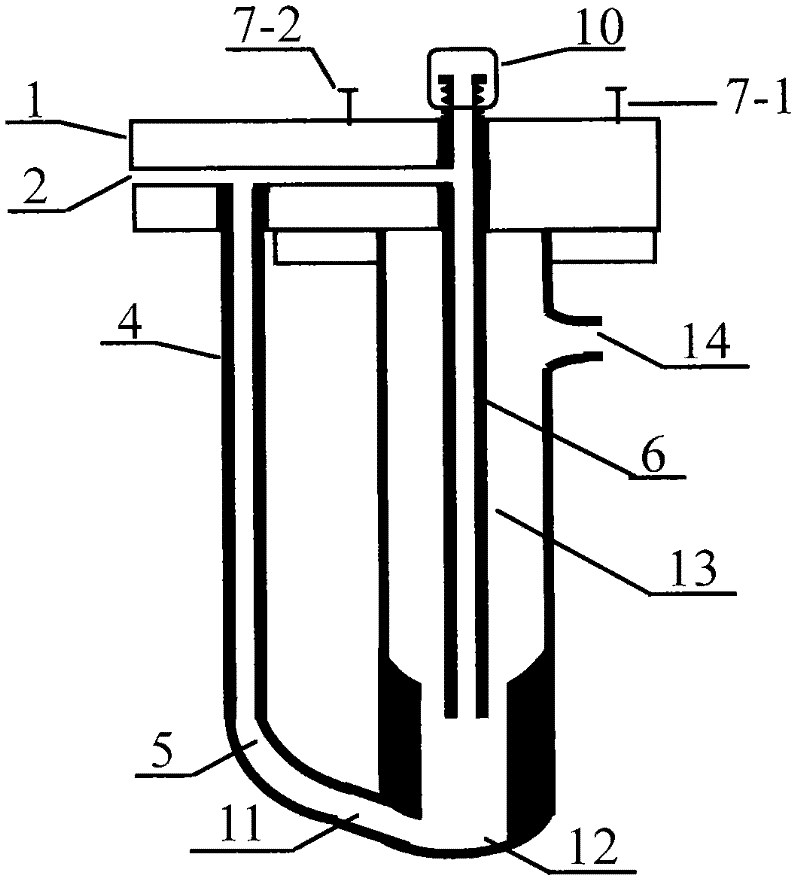

Method used

Image

Examples

Embodiment 1

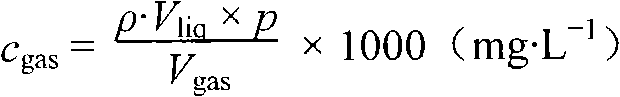

[0029] Set the system temperature of the spray gasification device to 40°C, and the gas flow rate (V gas )400mL·min -1 Next, absolute ethanol (density ρ 40℃ =0.7722g·mL -1 ) injection rate (V liq )0.04μL·min -1 . According to the following formula, calculate the prepared mass concentration of ethanol under the standard condition (0°C, 1atm) in the gas phase: 0.077mg L -1 .

[0030] c gas = ρ · V liq × p V gas × 1000 ( mg · L - 1 )

Embodiment 2

[0032] Set the system temperature to 40°C, the gas flow rate (V gas )3000mL·min -1 Next, absolute ethanol standard substance (density ρ 40℃ =0.7722g·mL -1 , purity 100%) injection rate (V liq )0.001μL·min -1 . According to the above formula, the prepared mass concentration of sarin under the standard condition (0°C, 1atm) in the gas phase is calculated as 0.26mg m -3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com