Oxygen carrier for preparing syngas from biomass, preparation method and applications thereof

An oxygen carrier and biomass technology, which is applied in the field of biochemical chain production of synthesis gas oxygen carrier preparation, can solve the problems of low concentration of product synthesis gas and low gasification rate, and achieves cheap raw materials, high activity and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

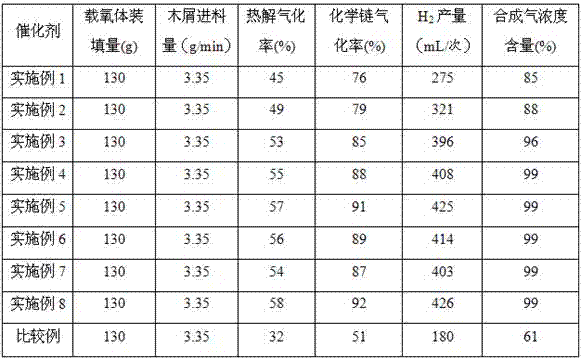

Examples

Embodiment 1

[0041] Take 36.3g Ni(NO 3 ) 2 ·6H 2 O, put it into a 500mL beaker, add 100mL of distilled water, and then place the beaker in a water bath at 80°C with a stirring speed of 400rpm. Take 34.3g La(NO 3 ) 3 ·6H 2 O, put it in a beaker with 100mL distilled water, stir until it is completely dissolved. Then add the lanthanum nitrate solution dropwise into the cobalt nitrate solution, and stir while adding dropwise. Take 40g of citric acid, the molar ratio of citric acid to the total amount of metal ions is 1.2:1, put it into a 100mL beaker and stir until completely dissolved, after stirring the above mixed solution for 30 minutes, slowly add the citric acid solution, dropwise While stirring. After stirring for 5 hours, the reddish-brown solution had been dehydrated and turned into a viscous gel. The gel was taken out and placed in a drying oven at 110° C. to dry overnight. Then take out the dried perovskite precursor, place it in a muffle furnace, raise the temperature from ...

Embodiment 2

[0044] Take 36.3g Ni(NO 3 ) 2 ·6H 2 O, put it into a 500mL beaker, add 100mL of distilled water, and then place the beaker in a water bath at 80°C with a stirring speed of 400rpm. Take 34.3g La(NO 3 ) 3 ·6H 2 O, put it in a beaker with 100mL distilled water, stir until it is completely dissolved. Then add the lanthanum nitrate solution dropwise into the cobalt nitrate solution, and stir while adding dropwise. Take 40g of citric acid, the molar ratio of citric acid to the total amount of metal ions is 1.2:1, put it into a 100mL beaker and stir until completely dissolved, after stirring the above mixed solution for 30 minutes, slowly add the citric acid solution, dropwise While stirring. After stirring for 5 hours, the reddish-brown solution had been dehydrated and turned into a viscous gel. The gel was taken out and placed in a drying oven at 110° C. to dry overnight. Then take out the dried perovskite precursor, place it in a muffle furnace, raise the temperature from ...

Embodiment 3

[0047] Take 36.3g Ni(NO 3 ) 2 ·6H 2 O, put it into a 500mL beaker, add 100mL of distilled water, and then place the beaker in a water bath at 80°C with a stirring speed of 400rpm. Take 34.3g La(NO 3 ) 3 ·6H 2 O, put it in a beaker with 100mL distilled water, stir until it is completely dissolved. Then add the lanthanum nitrate solution dropwise into the cobalt nitrate solution, and stir while adding dropwise. Take 40g of citric acid, the molar ratio of citric acid to the total amount of metal ions is 1.2:1, put it into a 100mL beaker and stir until completely dissolved, after stirring the above mixed solution for 30 minutes, slowly add the citric acid solution, dropwise While stirring. After stirring for 5 hours, the reddish-brown solution had been dehydrated and turned into a viscous gel. The gel was taken out and placed in a drying oven at 110° C. to dry overnight. Then take out the dried perovskite precursor, place it in a muffle furnace, raise the temperature from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com