Catalyst for medium and low temperature catalytic coal gasification for producing natural gas and preparation method thereof

A coal catalytic gasification and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of difficult catalyst recovery, catalyst deactivation, application scope It can solve the problems of narrow coal pulverized coal gasification, improve the gasification rate, and solve the effects of poisoning and deactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] To prepare single-component potassium salt catalytic coal powder, weigh 20g of coal powder, immerse it in 40ml of potassium carbonate solution, stir at room temperature to 90°C for 1 to 4 hours, then filter it with suction, and place it in a nitrogen atmosphere at 100 to 200°C Dry for 1 to 5 hours, then cool and sieve to obtain "K" catalytic coal powder, which is sealed and stored for later use, and the mass fraction of potassium / carbon is about 10%.

Embodiment 2

[0033] To prepare two-component catalytic coal powder, weigh 20g of coal powder, immerse it in 40ml of calcium nitrate solution, stir it at room temperature ~ 90°C for 1-4h, then filter it with suction and dry it in a nitrogen atmosphere at 100-200°C 1 to 5 hours, and then cooled and ground to obtain the pretreated sample.

[0034] Then take 10g of the pretreated sample, soak it in 40ml of potassium carbonate, stir it at room temperature ~ 90°C for 1 ~ 4h, then filter it with suction, dry it in a nitrogen atmosphere at 100 ~ 200°C for 1 ~ 5h, and then cool it. Sieve to get "K-Ca" catalytic coal powder, and keep it sealed for future use. Wherein the mass fraction of potassium / carbon is about 10%, and the mass fraction of calcium / potassium is about 30%.

Embodiment 3

[0036] To prepare composite multi-component catalytic coal powder, weigh 20g of coal powder, immerse it in 40ml of calcium nitrate solution, stir at room temperature to 90°C for 1 to 4 hours, then filter it with suction and dry it in a nitrogen atmosphere at 100 to 200°C 1 to 5 hours, and then cooled and ground to obtain the pretreated sample.

[0037] Then take 10g of the pretreated sample, immerse it in 40ml of potassium carbonate and nickel nitrate solution, stir at room temperature ~90°C for 1~4h, then filter it with suction, and dry it in a nitrogen atmosphere at 100~200°C for 1~5h. After cooling and sieving, "K-Ca-Ni" catalytic coal powder is obtained, which is sealed and stored for later use. The mass fraction of potassium / carbon is about 10%, the mass fraction of calcium / potassium is about 30%, and the mass fraction of nickel / potassium is about 20%.

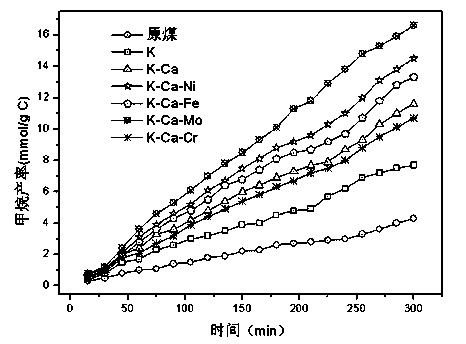

[0038] The following mainly examines the effects of different transition metal salts on the catalyst activity and sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com