Biomass castoff supercritical water fluid bed partial oxidation hydrogen-preparation device and method

A technology for biomass waste and hydrogen production device, which is applied in the fields of hydrogen production, chemical industry, bulk chemical production, etc. Low conversion efficiency and other problems, to achieve the effect of being conducive to centralized treatment and resource utilization, realizing pollution control and hydrogen production, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The gasification raw material used in the present invention may be biomass model compounds (glucose, cellulose, lignin, etc.), primary biomass waste (crop straw, various wastes, etc.) or coal. The following takes agricultural biomass straw as an example for illustration.

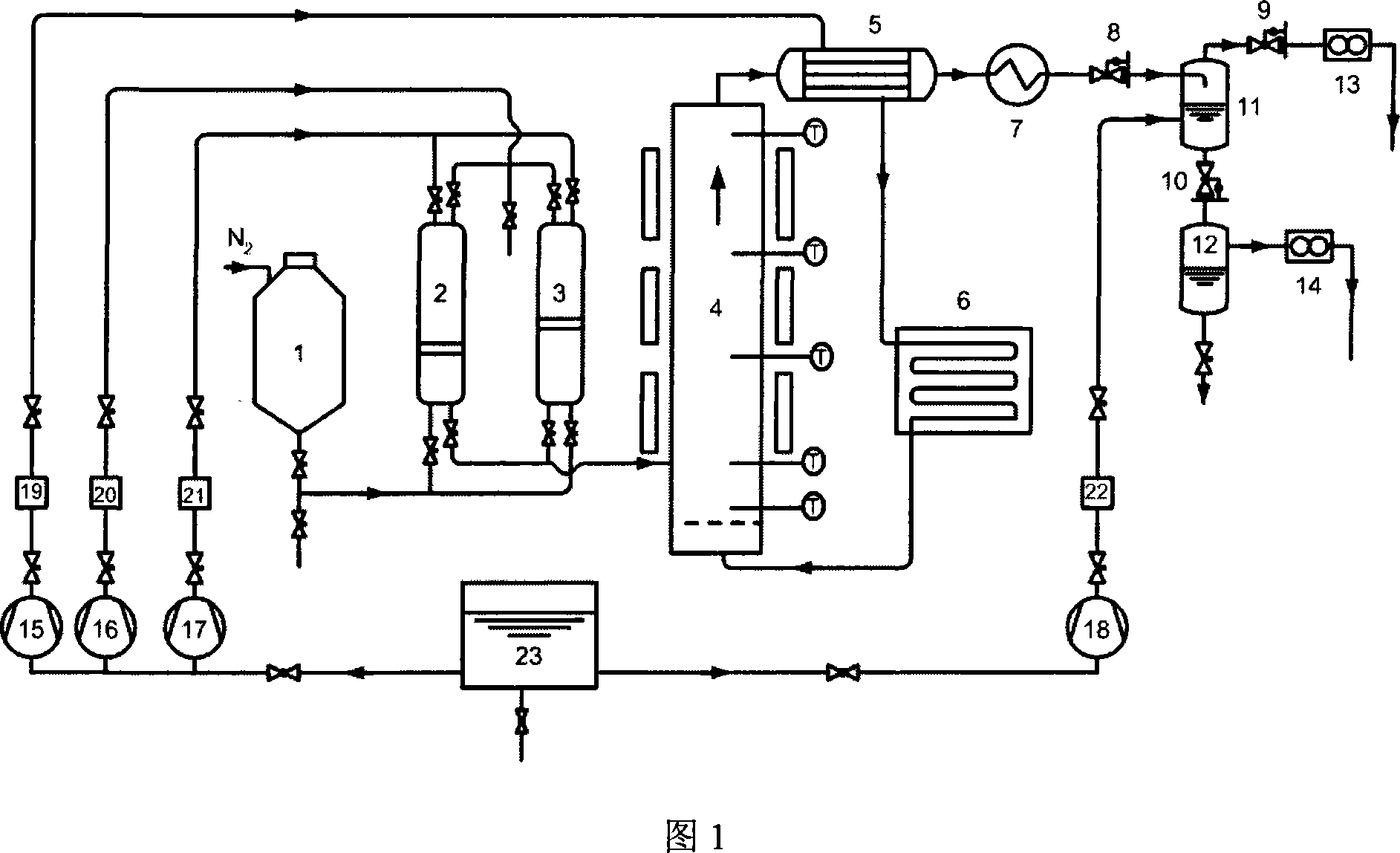

[0035] With reference to accompanying drawing 1, the first, the second feeder (2,3), the second, the 3rd high-pressure plunger pump (16,17), stock tank 1 communicate with each other by pipeline and valve in the device of the present invention, Composition charging system; Reactor 4 is communicated with the outlet of preheater 6, the first, the second feeder (2,3) outlet respectively; Heat exchanger 5 is respectively connected with reactor 4 outlet, first high pressure plunger pump 15 outlets , the inlet of the preheater 6 and the inlet of the cooler 7 are communicated; the outlet of the cooler 7 is communicated with the inlet of the first back pressure valve 8; the high pressure separator 11 is respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com