vertical fermenter

A vertical fermentation tank and vertical technology, applied in the chemical field of fermentation equipment, can solve the problems of products and microorganisms running away, heaters are easily damaged, and mycelium growth is affected, so as to facilitate growth and metabolism and improve fermentation Efficiency, reduced aeration and the effect of stirring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

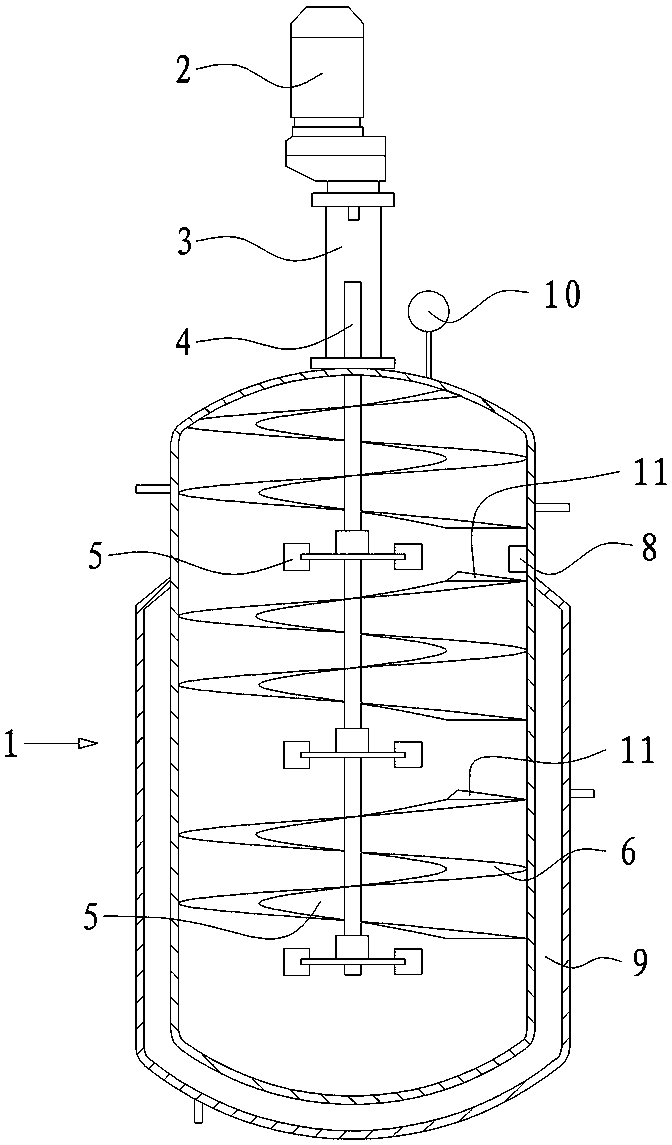

[0022] The vertical fermenter of present embodiment, as figure 1 As shown, it includes a vertical tank body 1, a motor 2 fixed above the tank body 1, a speed reducer 3 and a vertically arranged stirring shaft 4. The tank body 1 is a stainless steel tank body, and the tank body 1 is composed of an inner tank body, an outer shell body and a cooling chamber 9 arranged between the inner tank body and the outer shell body. The cooling chamber 9 is provided with a semicircular cooling coil close to the inner body.

[0023] The output end of the motor 2 is connected to the input end of the reducer 3, the output end of the reducer 3 is connected and fixed to the upper end of the stirring shaft 4, the lower end of the stirring shaft 4 penetrates into the tank body 1 and extends vertically to the bottom of the tank body, and the stirring shaft 4 A plurality of stirring paddles 5 are arranged at intervals at the lower end.

[0024] The inner wall of the tank body 1 is provided with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com