Self-sucking type nozzle in two phases of gas-fluid with structure of convex circular ring

A self-priming, nozzle technology, used in liquid injection devices, water aeration, injection devices, etc., can solve problems such as difficulty in adapting to different processes, inspiratory volume, and unsatisfactory dissolved oxygen rate, and improve inhalation and air flow. Liquid contact time, easy to popularize and implement, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

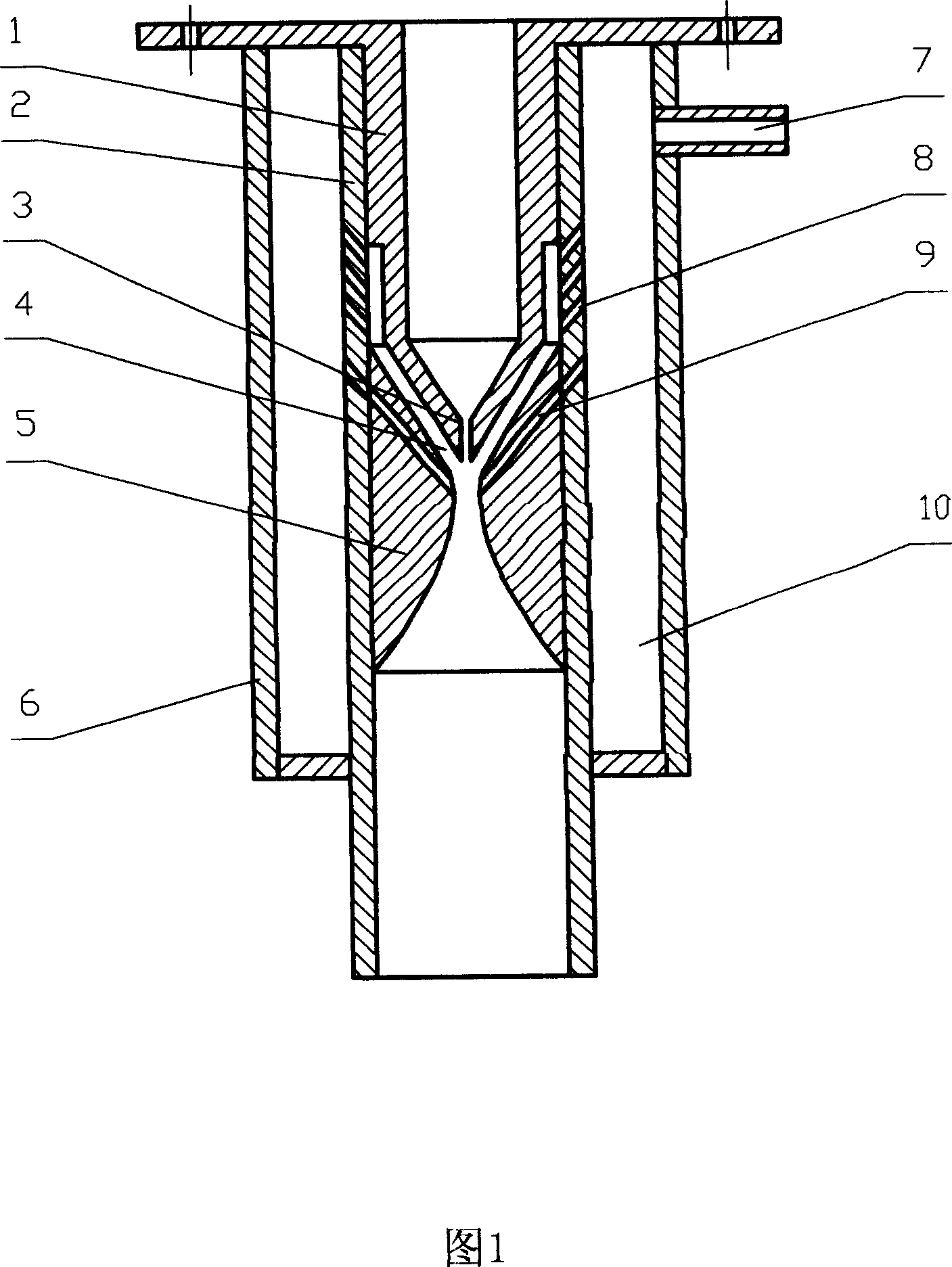

[0008] Referring to Figure 1, the nozzle is a cylindrical structure, the lower end is the nozzle outlet, and consists of three concentric cylinder sets of inner cylinder 1, middle cylinder 2, and outer cylinder 6, and the inner cylinder 1 suit is fixed on the middle cylinder 2, its lower end is a tapered liquid spray nozzle 3, the diameter of the liquid spray nozzle 3 should make the liquid flow rate between 10 ~ 40 m / s, the middle cylinder 2 in front of the liquid spray nozzle 3 has a built-in convex circle The ring body 5, the gap between the liquid spray nozzle 3 and the convex annular body 5 forms a ring-conical gap position 4, and the distance between the upper end surface of the convex annular body 5 and the lower end surface of the liquid spray nozzle 3 is the liquid spray nozzle 3 1 to 4 times the diameter, the smallest diameter in the middle and upper part of the convex ring body 5 is a constriction, the inner diameter of the necking is 1 to 4 times the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com