Gas turbine combustion-chamber for combusting ethanol fuel

A technology of gas turbines and ethanol fuels, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of structural strength of pollution emissions, incomplete universal use, low combustion efficiency, etc., achieve good ignition and flameout performance, and reduce carbon black Effect of smoke emission and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

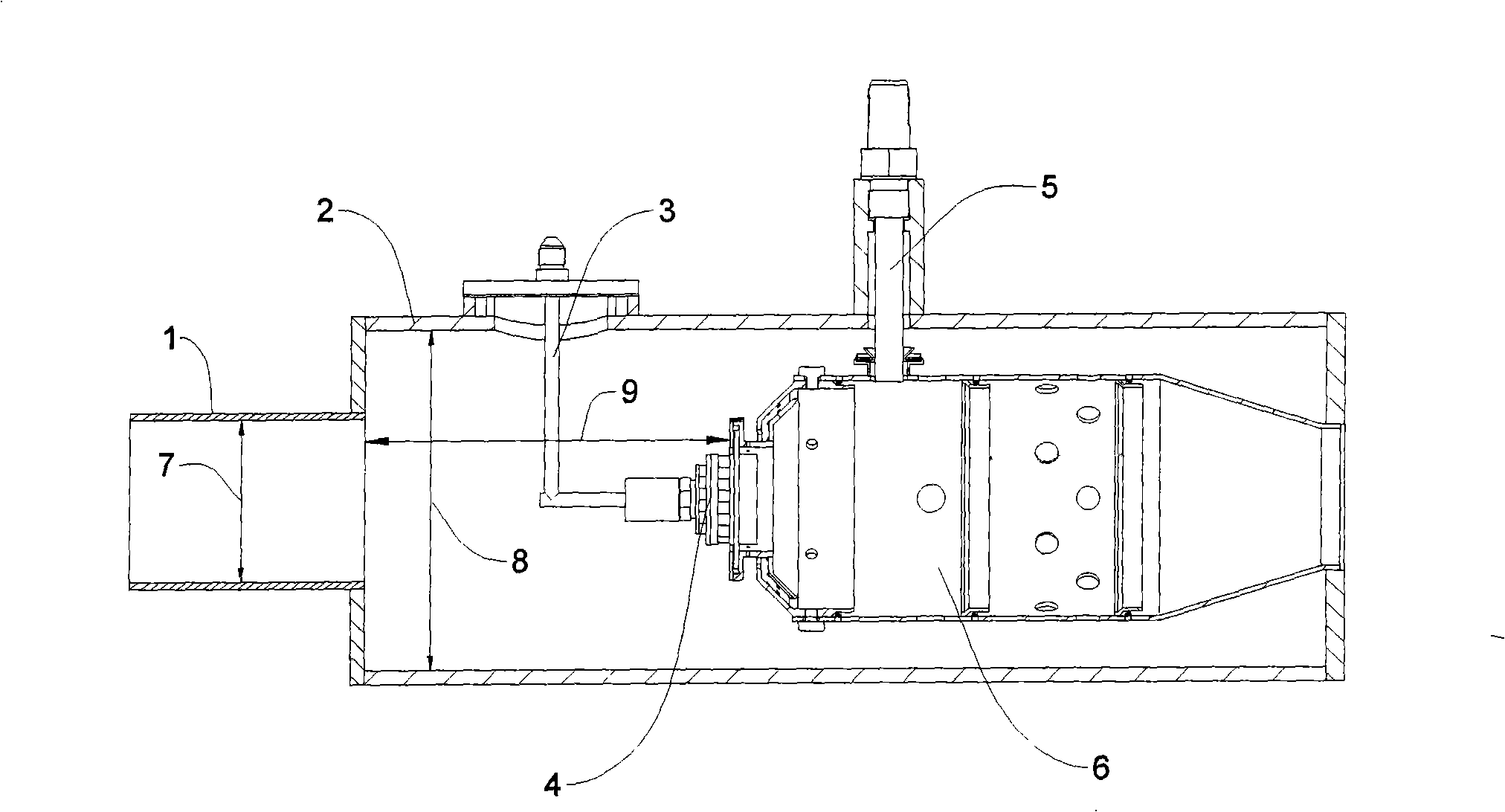

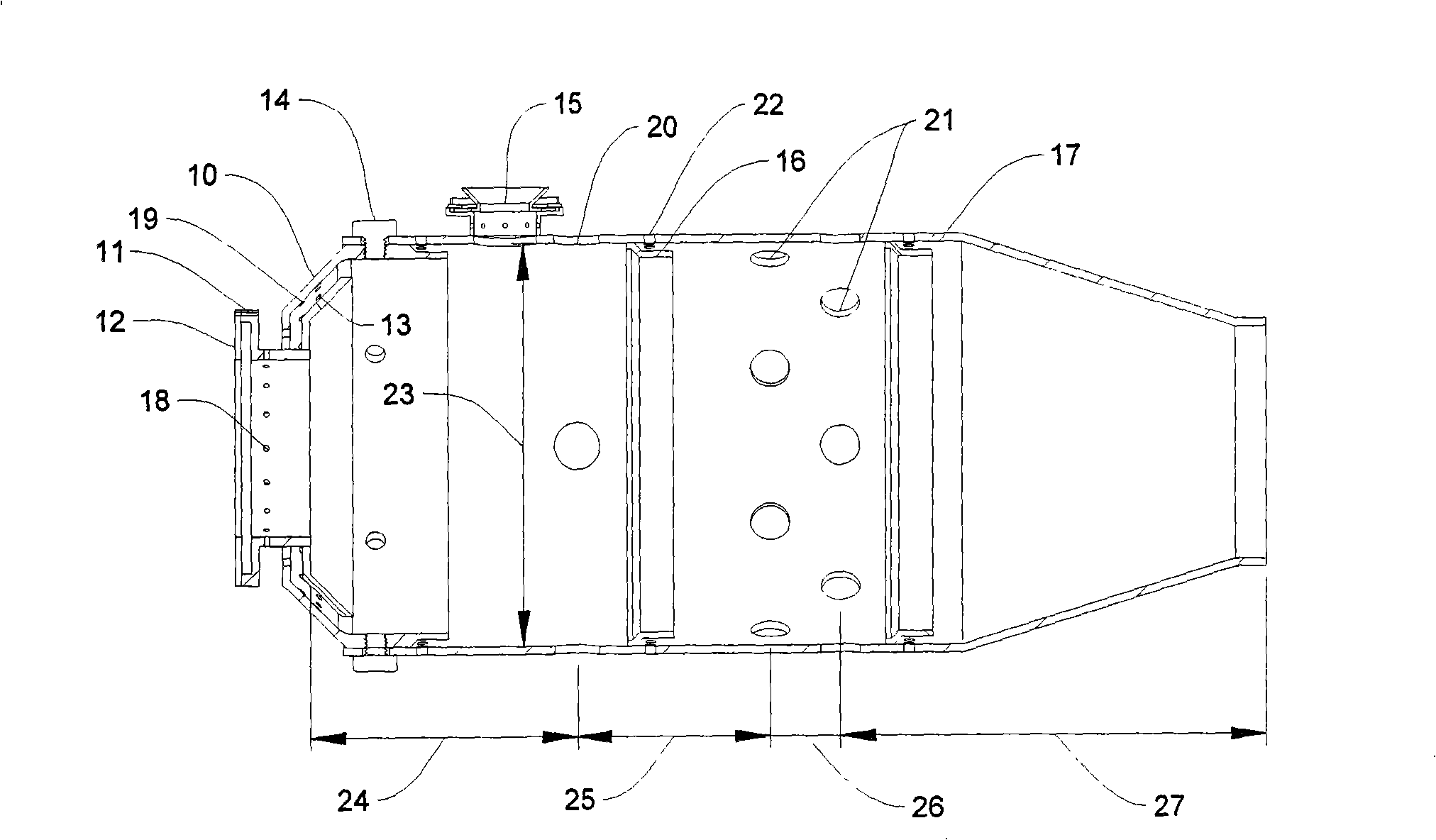

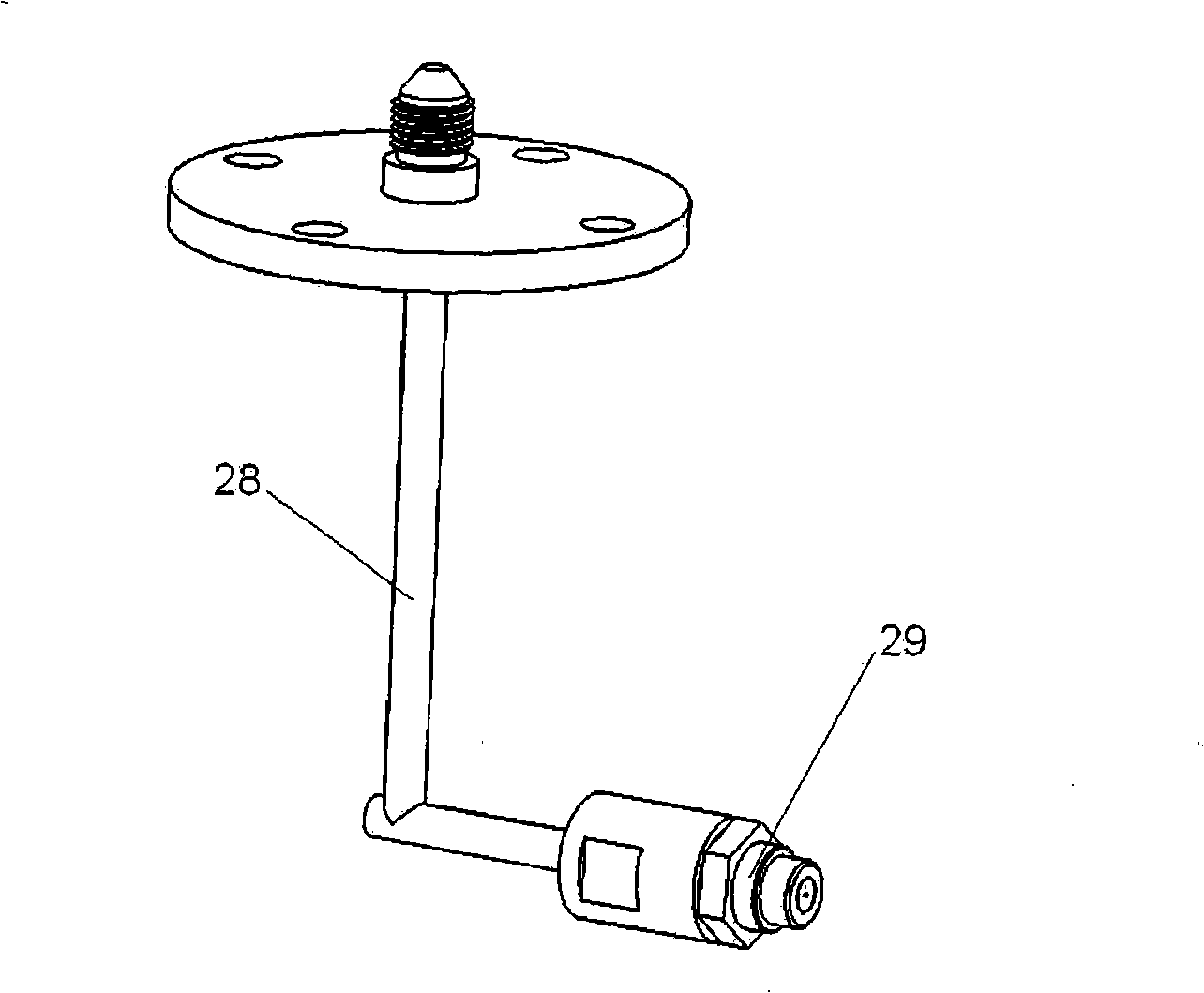

[0029] A gas turbine combustor burning ethanol fuel in this embodiment adopts a single-tube cylindrical structure, which is easy to install, disassemble and maintain, and is composed of a combustor casing 2 and a flame tube 6; figure 1 As shown, the inlet 1 of the combustion chamber is docked with the incoming flow of the compressor, and the air flow is introduced into the combustion chamber; it is welded with the casing 2 of the combustion chamber, and the flame tube 6 is welded or screwed to the casing 2 of the combustion chamber at the outlet ; The ethanol supply path 3 supplies liquid ethanol into the combustion chamber, and forms a fuel preparation system with the swirl device 4 to complete the atomization and evaporation of ethanol; The electric spark igniter 5 realizes the ignition start of the ethanol combustion chamber; the whole eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com