Gas Spargers and Silicone Fluidized Bed Reactors for Silicone Fluidized Beds

A technology of gas distributor and silicon fluidized bed, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased side reactions, low reactivity, and reduced conversion rate of methyl chloride, etc., to achieve operational flexibility and production Improve the cycle, improve the heat transfer effect, improve the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

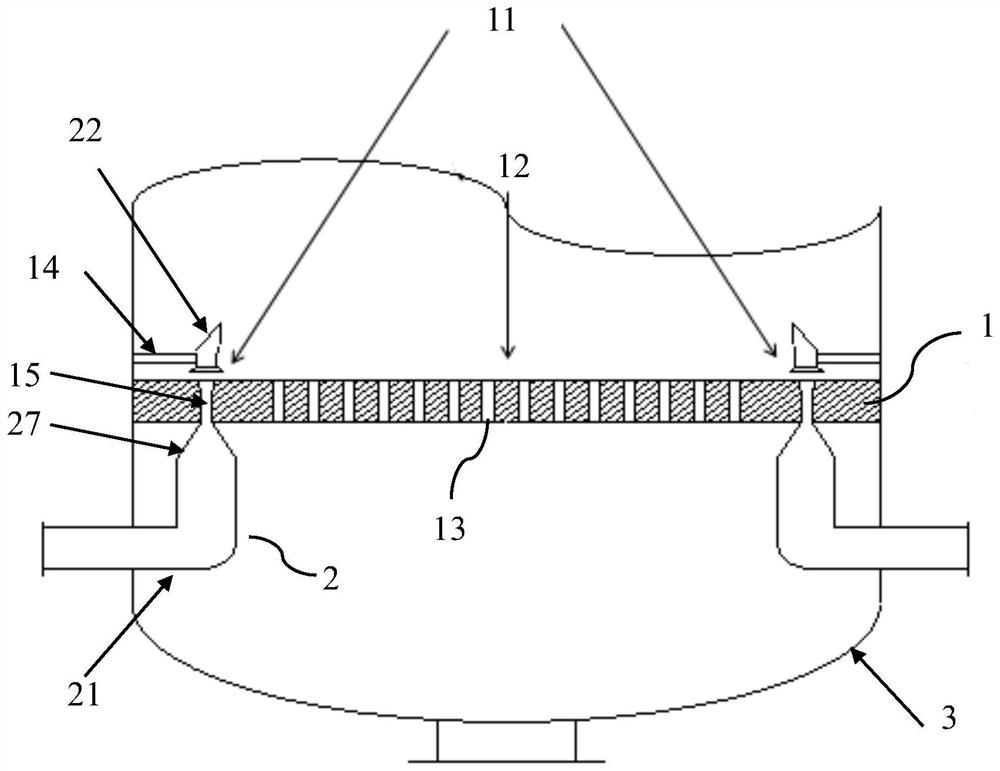

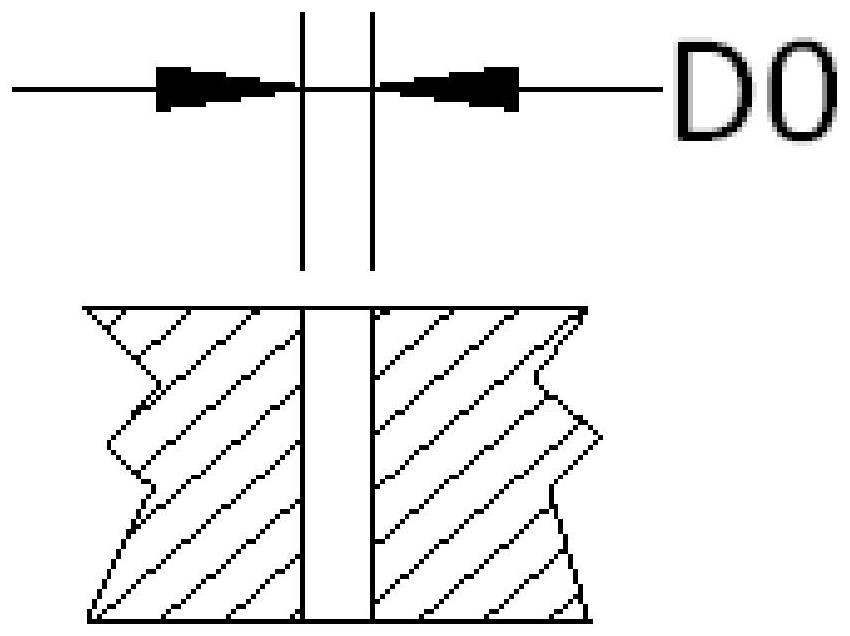

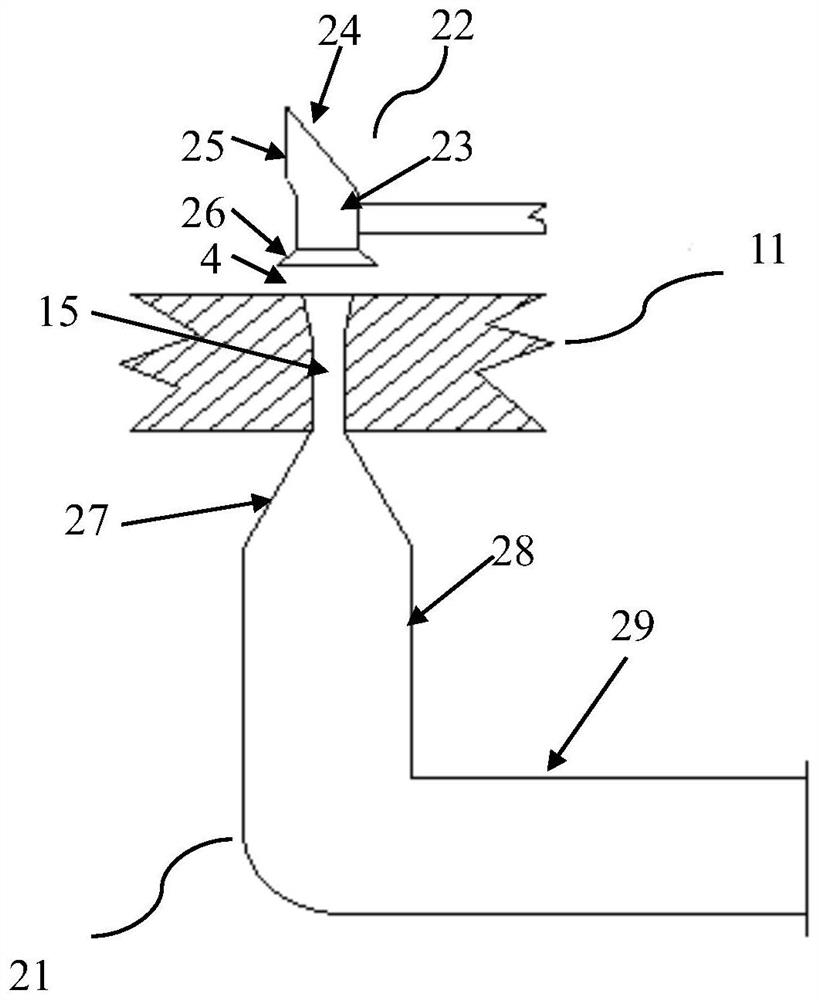

[0076] The gas distributor of the present invention is installed in a pilot organosilicon monomer fluidized bed synthesis reactor with a diameter of 1 m and a height of 6 m. Such as Figure 1-6 As shown, the central area 12 accounts for 75% of the total area of the gas distribution plate 1 , and the side wall area 11 accounts for 25% of the total area of the gas distribution plate 1 . The central area is evenly provided with equal-diameter vertical air holes 13 with an opening ratio of 1.5%; the diameter D0 of the vertical air holes 13 is 3 mm, and the air inlet pressure of the vertical air holes 13 is 0.35 MPa. Three particle guide devices 2 are equidistantly and symmetrically distributed along the annular side wall area 11 . The air outlet 25 of the guide tube 22 is set to face directly above the central area 12 .

[0077] The inlet pipe 21 is connected with the jet air hole 15 through the frustum-shaped reducing pipe 27, the gas inlet pressure is 1.5MPa, the cone angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com