Method for controlling combustion atmosphere in large-scale walking beam type plate blank heating furnace

A slab heating and walking beam technology is applied in the maintenance of heating chambers, heat treatment furnaces, furnace control devices, etc. It can solve the problems of not yet established heating furnace atmosphere monitoring system, etc., achieve significant environmental protection effects, increase furnace temperature, reduce Effect of Slab Burn Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

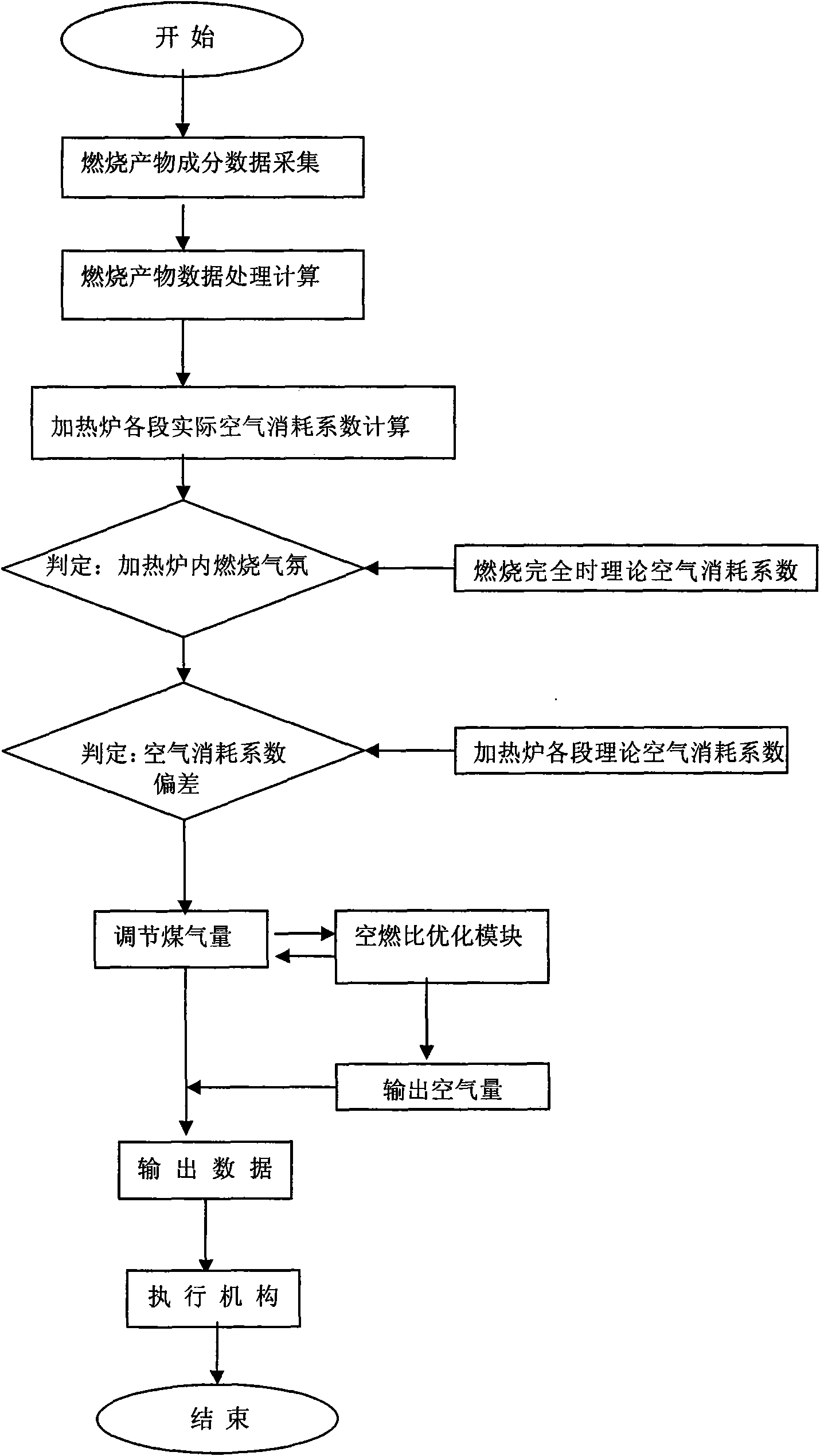

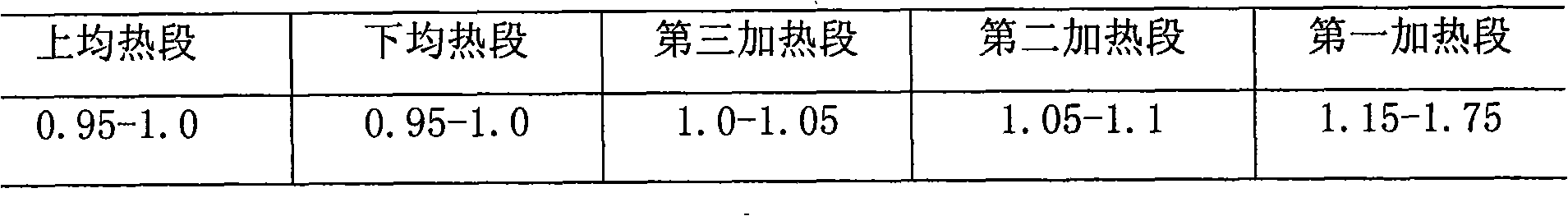

[0017] The key technology for controlling the combustion atmosphere of a large-scale walking beam slab heating furnace lies in the organic combination of the monitoring of the flue gas composition of the combustion system and the exhaust system. The secondary control controls the heating of the slab by switching the reversing valve. In a very short period of time, the actual air consumption coefficient of each section of the furnace is determined, compared with the theoretical air consumption set for each section, and the oxidation-reduction atmosphere in the furnace is determined. Adjust the air, The gas ratio is adjusted to adjust the gas and combustion air flow to achieve complete combustion, to ensure that the heat load of the heating furnace meets the heating demand of the slab, and at the same time reduce the oxidized burning loss of the slab. Taking Shougang Qinhuangdao Metal Material Co., Ltd.’s 4300mm rolling line wide and thick plate 2# heating furnace as an example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com