Vehicle-mounted slag-raking machine for converter, and use method

A vehicle-mounted, slag removal machine technology, which is applied in the direction of mechanical cleaning, manufacturing converters, manufacturing tools, etc., can solve the problems that the slag cannot continue to be poured out, and the molten iron is poured out, so as to reduce the consumption of converter lime, increase the alkalinity, reduce the The effect of steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

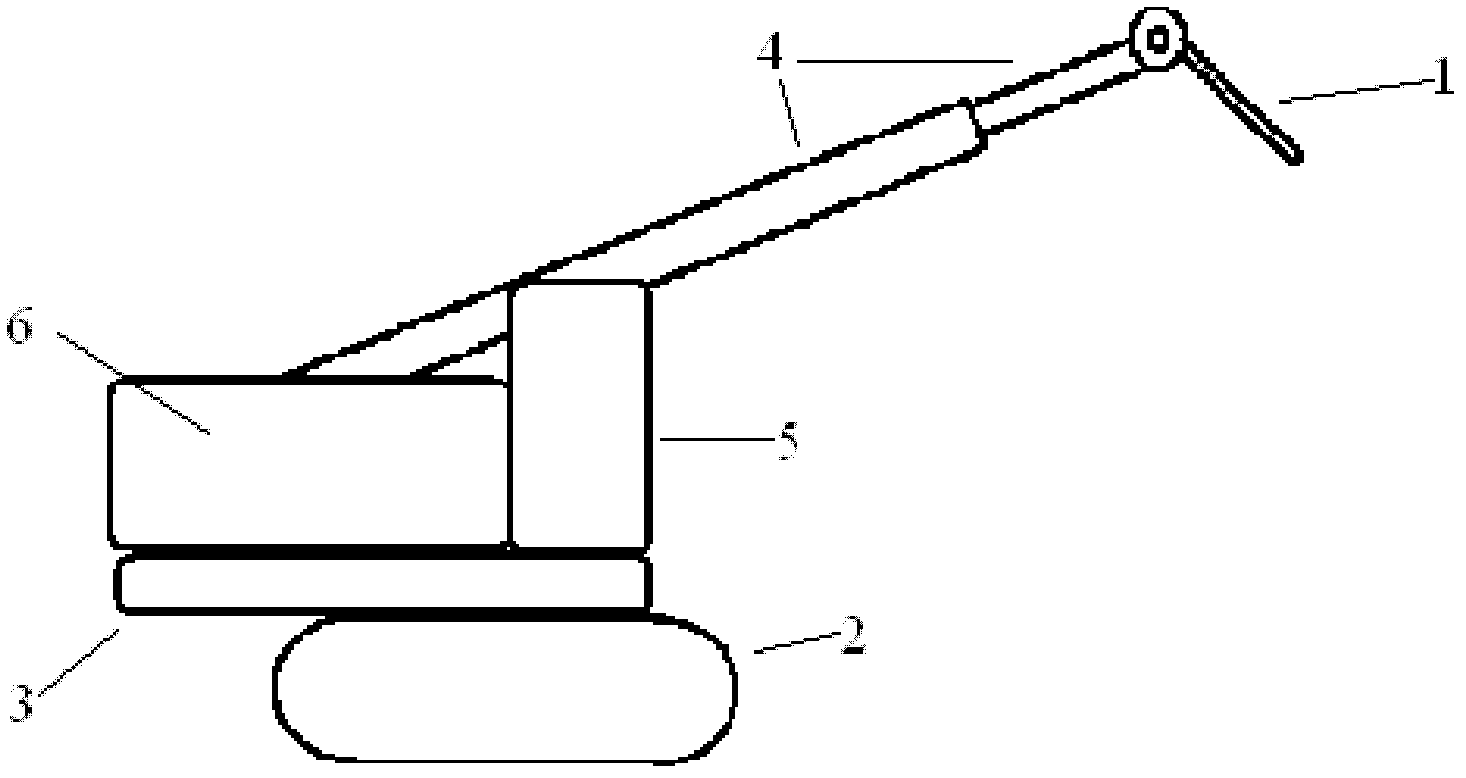

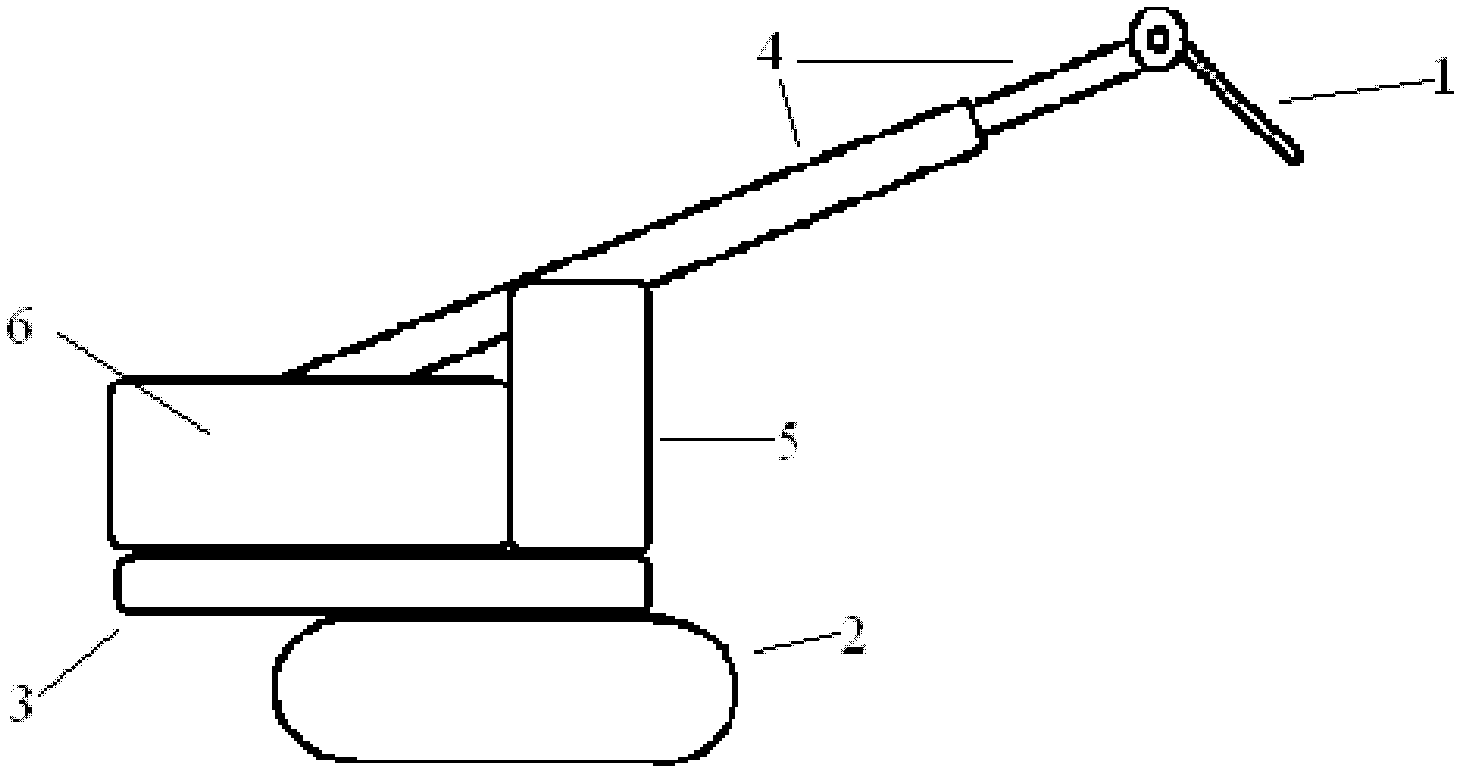

[0019] The vehicle-mounted slag removal machine for converters of the present invention comprises a slag removal board, a traveling chassis, a rotary middle plate, a telescopic working arm, a driver's cab, and a power system. The slewing center plate is above the walking chassis, the power system is on the left side directly above the slewing center plate, the cab is on the right side directly above the slewing center plate, and the power system is adjacent to the cab; one end of the telescopic working arm is connected to the power system, and the other end Connect the slag scraper. The slag removal board is made of high temperature resistant steel plate with a width of 0.4m, a height of 0.5m and a thickness of 8cm.

[0020] The vehicle-mounted slag removal machine for the converter of the present invention is a vehicle-mounted slag removal device, the locomotive can travel on the converter platform, and the slag removal object is the slag in the converter furnace.

[0021] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com