Converter oxide and nitrogen top-blown dephosphorizing method

A converter, oxygen and nitrogen technology, applied in the manufacture of converters, etc., can solve the problems of unfavorable decarburization furnace heat balance, reduced dephosphorization effect, low carbon content of molten iron, etc., to inhibit the decarburization reaction, improve the gas supply intensity, prevent The effect of slag overflow at the furnace mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

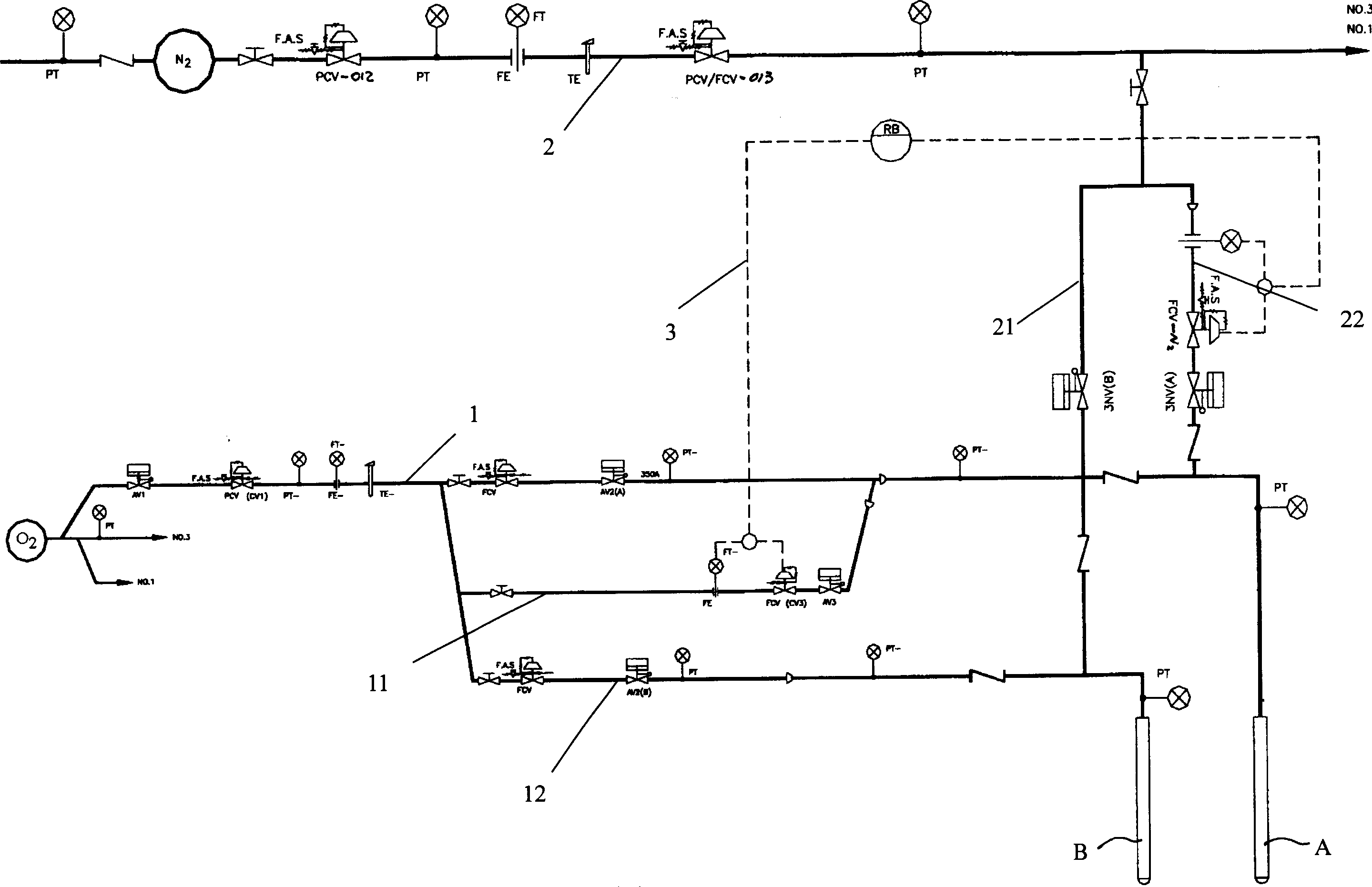

[0026] like figure 2 As shown, the converter oxygen nitrogen top-blowing dephosphorization method described in the present invention uses top-blowing oxygen nitrogen and bottom-blowing nitrogen in the top-bottom double-blowing converter to carry out dephosphorization treatment; wherein, the top-blowing oxygen lance A and the oxygen pipeline 1 and the oxygen branch pipeline 11 are connected; a nitrogen branch pipeline 22 is added at the main pipeline at the inlet of the top-blown oxygen lance A to communicate with the nitrogen pipeline 2, and the gas control valves FCV and 3NV (A ), check valve, etc., through the control circuit 12, the nitrogen branch pipeline 22 and the oxygen branch pipeline 11 are associated with the control, so that the top-blown oxygen lance A has two kinds of gas source control modes. The control and switching of pipeline 1 and nitrogen pipeline 2 are carried out with nitrogen and oxygen mixed blowing or oxygen / nitrogen intermittent blowing.

[0027] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com