Premelting molten iron pretreatment dephosphorization agent

A technology of hot metal pretreatment and dephosphorization agent, applied in the field of dephosphorization agent for molten iron pretreatment, can solve the problems of component segregation, increase pretreatment time, difficult storage and transportation, etc., achieve fast melting speed and reduce heat Effects of loss, ease of storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

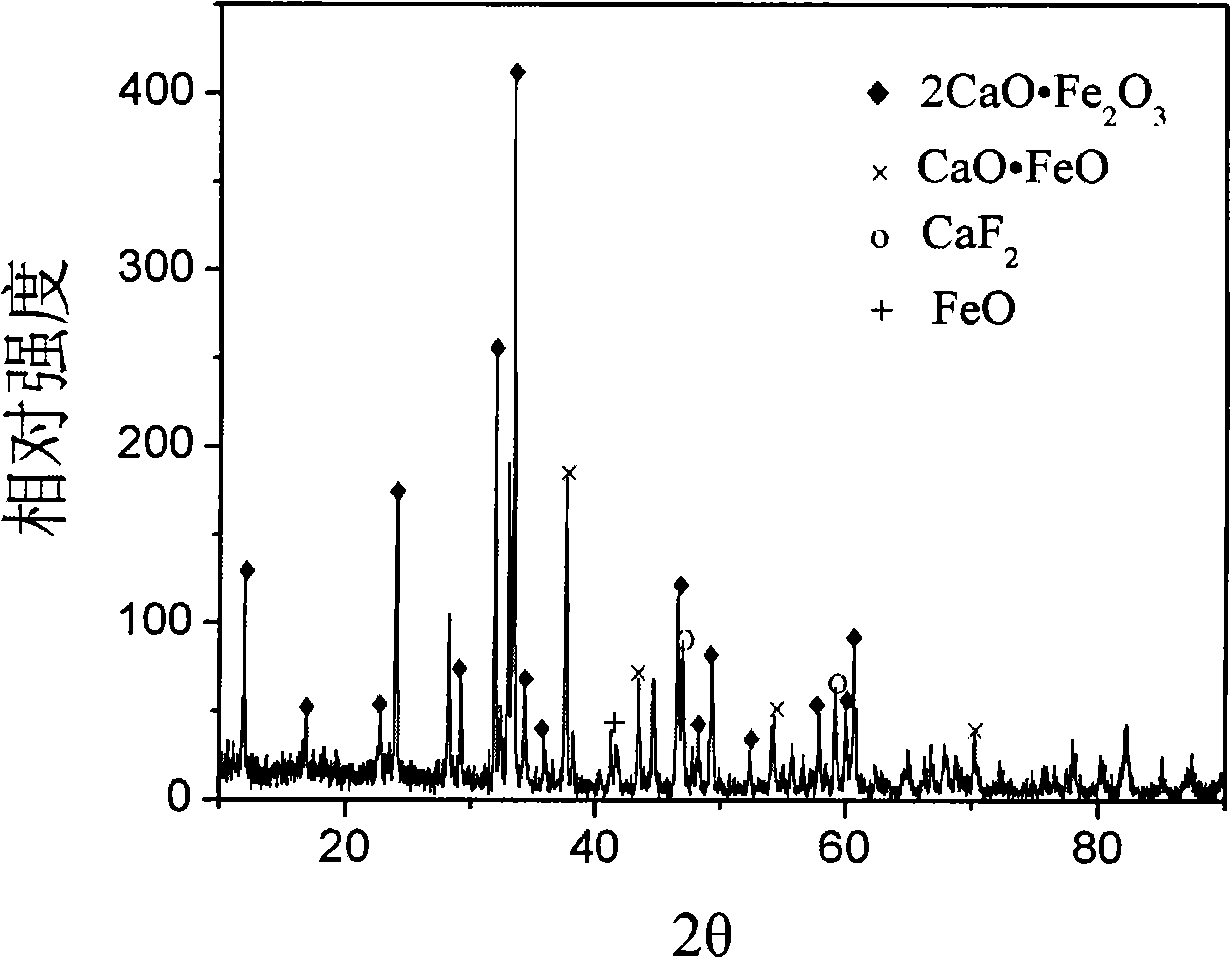

Image

Examples

Embodiment 1

[0034] In this embodiment, the composition and weight percentage of the pre-melted hot metal pretreatment dephosphorization agent are: active lime: 40%, rolling steel oxide scale: 50%, fluorite: 10%.

[0035] The CaO content in the above-mentioned activated lime is ≥90%. CaF in fluorite 2 Content ≥ 88%.

[0036] For the pre-melted hot metal pretreatment dephosphorization agent in this embodiment, the raw materials of the formula are mixed according to the ratio before use, and then heated to 1250°C to 1400°C in the slag melting furnace to melt into liquid slag, and then it is taken out of the furnace and cooled rapidly , broken into granules. The dephosphorization effect of using this pre-melted molten iron pretreatment dephosphorization agent is as follows: the phosphorus content of the molten iron before treatment is 0.21%, and after 3 minutes of dephosphorization treatment, the phosphorus in the molten iron can be reduced to 0.0081%, and the dephosphorization rate is 96.1...

Embodiment 2

[0038] In this embodiment, the composition and weight percentage of the pre-melted hot metal pretreatment dephosphorization agent are: active lime: 49%, rolled steel oxide scale: 45%, fluorite: 6%. All the other are the same as in Example 1, the dephosphorization effect of using this premelting type molten iron pretreatment dephosphorization agent is: the phosphorus content of molten iron before treatment is 0.23%, and the phosphorus in molten iron can be reduced to 0.049% through 3min dephosphorization treatment, The dephosphorization rate was 78.7%. After 10 minutes of dephosphorization treatment, the phosphorus in the molten iron was reduced to 0.0077%, and the dephosphorization rate was 96.65%. After that, the phosphorus in the molten iron basically remained at a level of less than 0.01%.

Embodiment 3

[0040] In this embodiment, the composition and weight percentage of the pre-melted hot metal pretreatment dephosphorization agent are: active lime: 44%, rolled steel oxide scale: 50%, fluorite: 6%. All the other are the same as in Example 1, using this pre-melt type molten iron pretreatment dephosphorization agent, the phosphorus content of the molten iron before treatment is 0.19%, and the phosphorus in the molten iron can be reduced to 0.011% through 3min dephosphorization treatment, and the dephosphorization rate is 94.21%; after 10 minutes of dephosphorization treatment, the phosphorus in the molten iron was reduced to 0.0052%, and the dephosphorization rate was 97.26%. After that, the phosphorus in the molten iron basically remained at a level of less than 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com