Method for preparing degreased soybean meal iron storage polypeptide by protease and application

A protease and soybean meal technology, which is applied in the field of preparing defatted soybean meal iron storage polypeptides, can solve the problems of affecting the protein stability of iron absorption, affecting the effect of iron supplementation, accelerating the release of iron ions, etc., achieving broad development potential and application prospects, and improving biological Utilization, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

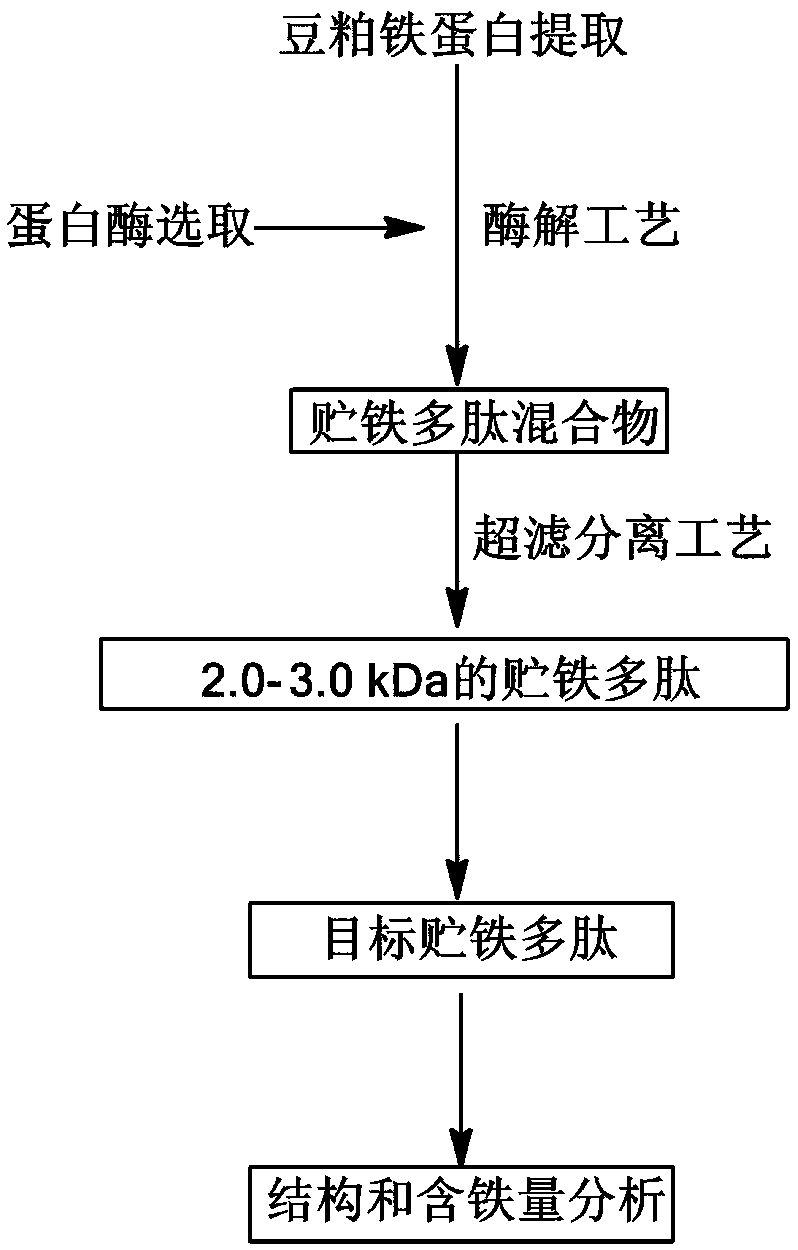

[0034] A method for preparing defatted soybean meal iron-storing polypeptide by using protease, the steps are as follows:

[0035] Using defatted soybean meal as raw material, the ferritin is extracted and separated by water extraction, the iron-containing polypeptide components are obtained by proteolysis technology, and the iron-storing polypeptide with high iron content is obtained by further applying the hierarchical ultrafiltration technology.

[0036] Preferably, the specific steps are as follows:

[0037] (1) Utilize defatted soybean meal as raw material, soak soybean meal with 0.05-0.10M phosphate buffer solution, the pH of the phosphate buffer solution is 7.0, and it contains polyvinylpyrrolidone with a mass percentage of 1%, phosphate buffer solution: soybean meal The mass ratio is 10-15:1, the soaking time is 6-8 hours, and then homogenized with an internal cutting homogenizer for 2-3 minutes to obtain crude protein extract;

[0038] (2) Add MgCl with a concentrati...

Embodiment 2

[0049] A method for preparing defatted soybean meal iron-storing polypeptide by using protease, the steps are as follows:

[0050] (1) Preparation of soybean meal soybean ferritin

[0051] Select the defatted soybean meal as raw material, soak the soybean meal in distilled water at 4°C overnight, add 2 times the volume of buffer solution (containing 0.05M phosphate buffer, pH 7.0, and 1% polyvinylpyrrolidone by mass percentage), Soak for 7 hours, and homogenize for 2 minutes with an internal cutting homogenizer to obtain a crude protein extract. The crude protein extract can also be filtered with gauze to remove bean dregs and take the supernatant.

[0052] A concentration of 50 mM MgCl was added to the crude extract 2 After the crystals are dissolved, immediately centrifuge at 4800g for 5min, discard the precipitate, and after the supernatant is allowed to stand for 20min, add trisodium citrate crystals with a concentration of 70mM and let stand overnight. liquid. Add 1.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com