Gradient functional material synthesis and additive manufacturing integrated mechanism

A gradient functional material and additive manufacturing technology, applied in the field of additive manufacturing, can solve the unseen problems of FGM material synthesis and additive manufacturing integration mechanism and technology, singleness, etc., achieve broad market prospects and development potential, and broaden applications area, the effect of improving molding efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings, and preferred embodiments described herein are intended to illustrate and explain the present invention, and is not intended to limit the invention.

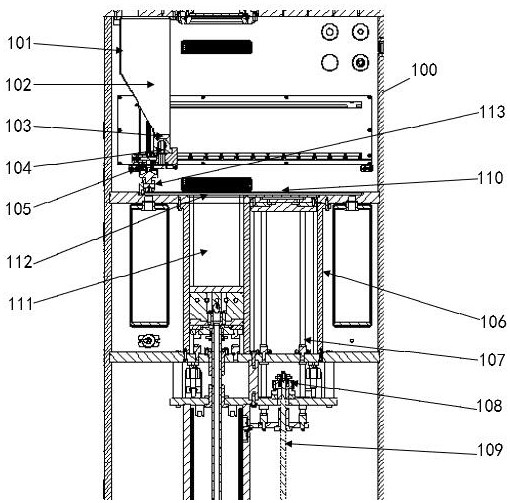

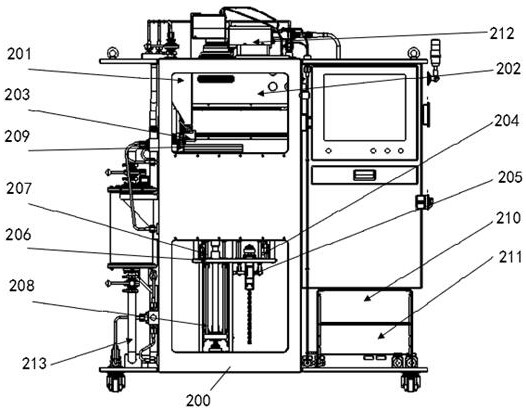

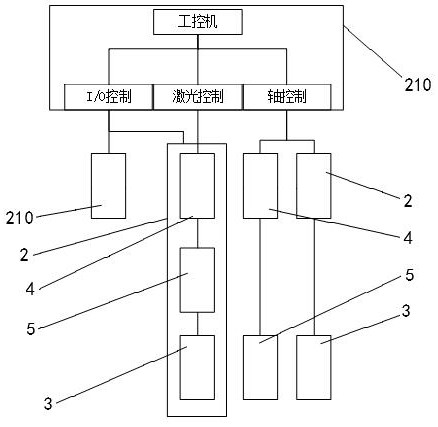

[0028] Refer to the instructions Figure 1-3 A gradient functional material synthesis and additive manufacturing integrated mechanism of this embodiment, including a bracket 100, a housing 200, a feed chamber servo drive system 2, a feed chamber lifting mechanism 3, a molding cabinet servo drive system 4, molding The compensation mechanism 5, the spray mirror control card 7, the spray mirror 8, the laser 9, the CNC system 210, the servo drive system 211, the laser system 212, and the atmosphere system 213, the bracket 100 fixedly mounting powder and powder mechanism, The housing 200 is fixedly mounted to mount FGM material synthesis and adding material manufacturing integrated mechanism, which includes the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com