Polylactic acid modified material containing plant fibers and preparation method thereof

A technology of modified materials and plant fibers, applied in the field of polylactic acid modified materials, can solve the problems of underutilization of cellulose, and achieve the effects of low density, reduced production cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

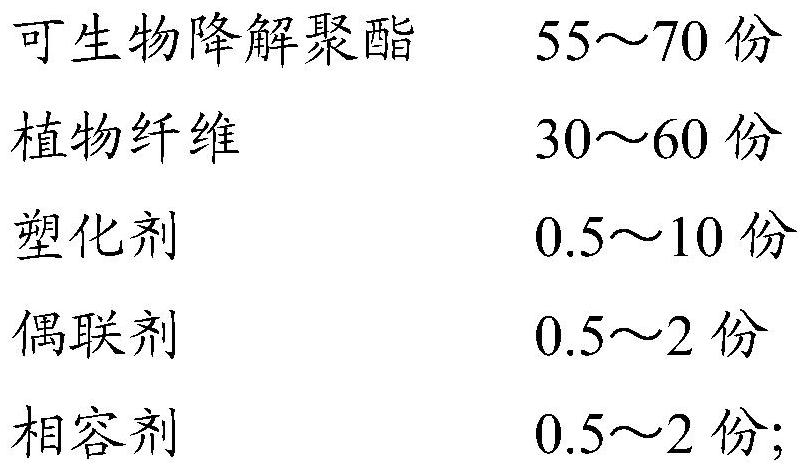

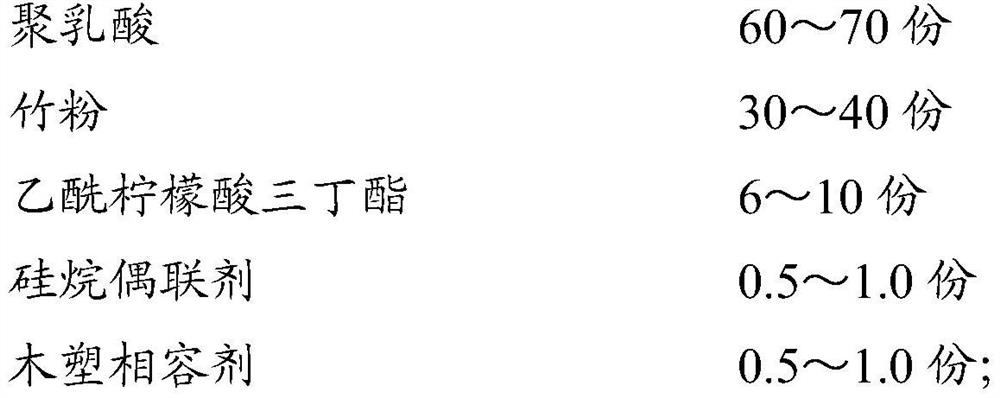

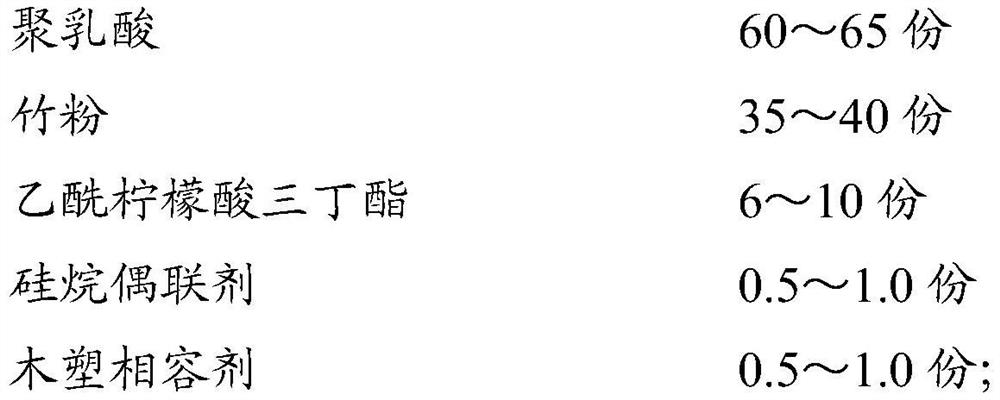

[0054] This embodiment provides a polylactic acid modified material containing plant fibers, and the raw materials for preparing the modified material are composed of the following materials in parts by weight:

[0055]

[0056] Among them, PLLA (L-polylactic acid) has an optical purity of 98.5%, a weight-average molecular weight of 130,000, and a melt flow index of 12.0g / 10min (at 190°C, under a weight pressure of 2.16kg);

[0057] Bamboo powder is passed through a 200 mesh sieve, with an ash content of 0.4%;

[0058] ATBC was purchased from Zibo Shiheng Chemical Co., Ltd.;

[0059] KH550 was purchased from Yizheng Tianyang Chemical Co., Ltd.;

[0060] YS-5031 was purchased from Guangzhou Yuantai Synthetic Materials Co., Ltd.

[0061] The preparation method of this polylactic acid modified material is:

[0062] 1) Dry PLLA at -0.1Mpa, 80°C for 30 minutes; dry bamboo powder at 65°C for 90 minutes;

[0063] 2) The preparation adopts a combination of twin-screw units, spe...

Embodiment 2

[0068] The difference between this embodiment and the embodiment is that the bamboo powder in the embodiment 1 is replaced with wheat straw, and the consumption is unchanged. Other raw materials are all unchanged. The wheat straw is deashed and pulverized, with an ash content of 8.7%, and passed through a 200-mesh sieve. The preparation method refers to the preparation method of Example 1.

Embodiment 3

[0070] The difference between this embodiment and the embodiment is that the PLLA in the embodiment 1 is replaced with PDLA, and the dosage remains unchanged. Other raw materials are all unchanged. Specifically, the properties of PDLA (dextrorotary polylactic acid) are as follows: optical purity 96.5%, weight average molecular weight 112,000, melt flow index 14.2g / 10min (at 190°C, 2.16kg weight pressure).

[0071] During the granulation process, due to the high melting temperature of PDLA, the temperature in each area of unit 1 was raised by 20°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com