A composite heat treatment process for improving surface compactness of nitrocarburizing strengthening layer

A composite heat treatment and nitrocarburizing technology, applied in the field of surface heat treatment, can solve the problems of prolonging the austenitizing treatment time, reducing the density, increasing the degree of nitrogen loss, etc., to improve the surface density and comprehensive performance, Eliminates the effects of weak areas of surface hardness, brittle toughness and wear resistance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

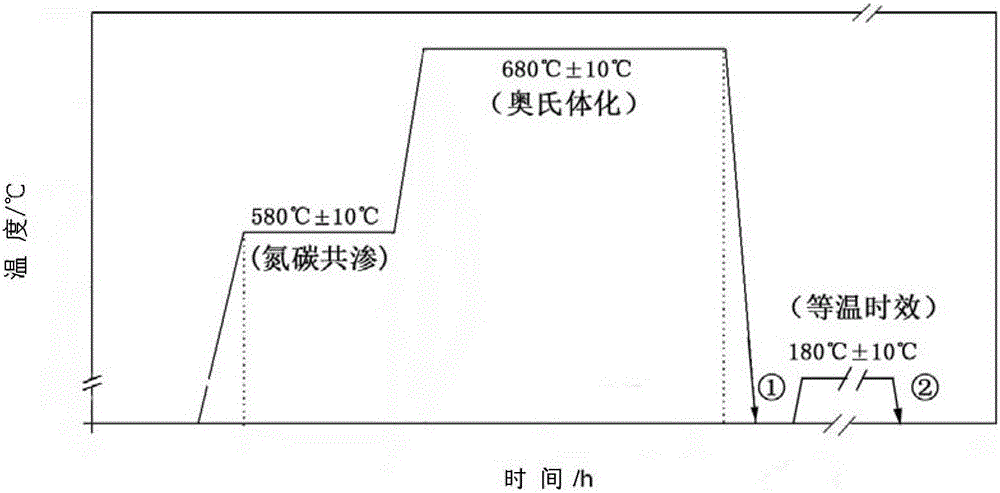

Method used

Image

Examples

Embodiment 1

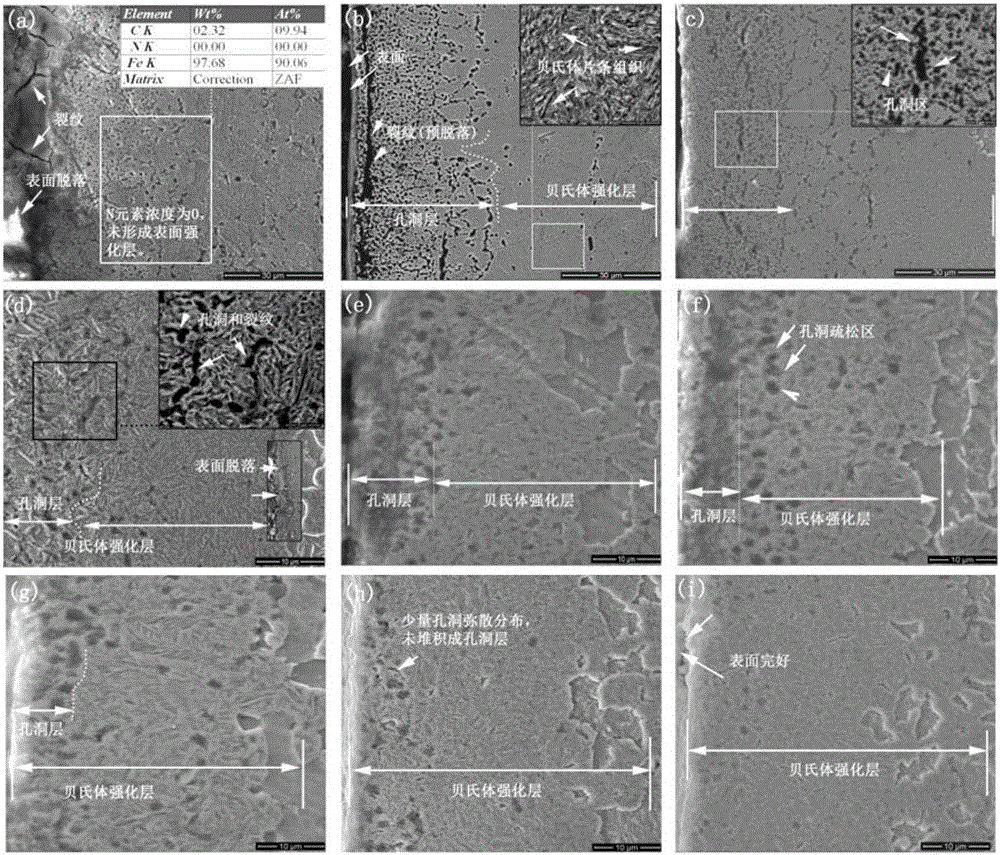

[0077] The sample is made of No. 10 carbon steel, and there are 9 groups of samples in total. After 2 hours of bulk treatment, water quenching, and then isothermal aging at 180°C±10°C for 14 hours, see Table 1 for the specific process parameters and the strengthening layer of the sample (thickness of the hole layer is adopted FEI Quanta200 type Observation by scanning electron microscope, and measure with electronic ruler, take the average value of 20 measurement data for each value; surface hardness adopts HV-1000Z type Microhardness tester test, the experimental load is 0.49N, the duration is 15s, and the average value of 20 test points is taken for each value);

[0078] Table 1

[0079]

[0080] use FEI Quanta200 type Environmental scanning electron microscope was used to characterize the cross-section strengthening layer of 9 groups of samples, and the results are shown in the attached figure 2 ;from figure 2 see:

[0081] Samples (a) to (c) with nitrocarburiz...

Embodiment 2

[0095] The sample is made of 0Mn12Ni2 alloy steel, and the test method and operation steps are the same as those of Scheme 1. One group of test pieces, after ferrite nitrocarburizing at 580°C±10°C, is heated to 680°C±10°C with the furnace, nitrogen protection Austrian After tempering treatment for 2 hours, water quenching, and then isothermal aging at 180℃±10℃ for 14 hours.

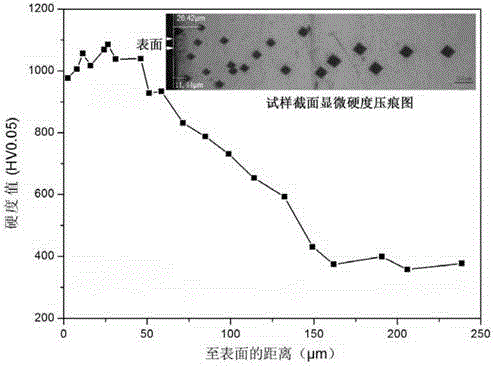

[0096] Nitrocarburizing treatment time is 1h, and the experimental nitriding potential value is 0.42atm -1 / 2 . The microhardness test was carried out on the surface and section of the sample by a microhardness tester, and the results are shown in the appendix Image 6 , from attached Image 6 It can be seen that the nitriding potential value K in nitrocarburizing treatment N 0.42atm -1 / 2 , when the nitriding time is 1h, the surface hardness of the specimen reaches 987HV, and the thickness of the strengthening layer is about 100μm.

[0097] From the experimental data and test results of Examples 1 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com