Electric servo main transmission bus punching device

A main drive, electric servo technology, applied in metal processing equipment, manufacturing tools, perforation tools, etc., can solve the problems of 5S indicators affecting the user's production site, oil leakage in the hydraulic part, and high maintenance costs, to omit cooling links and avoid energy. The effect of waste, precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

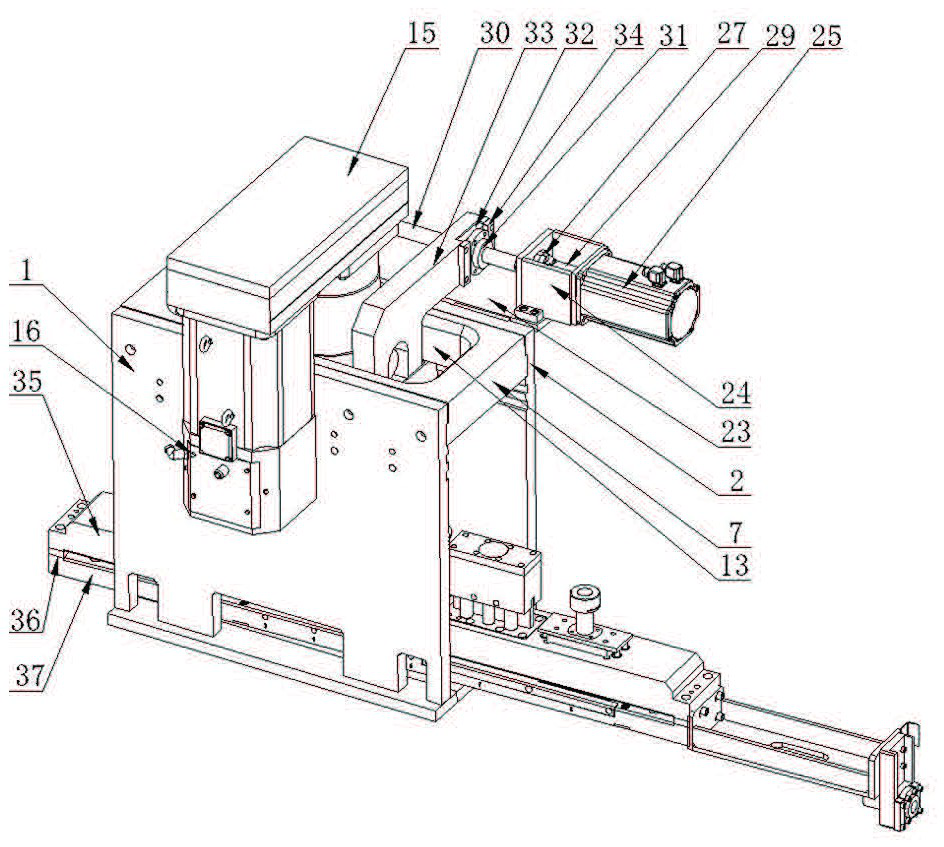

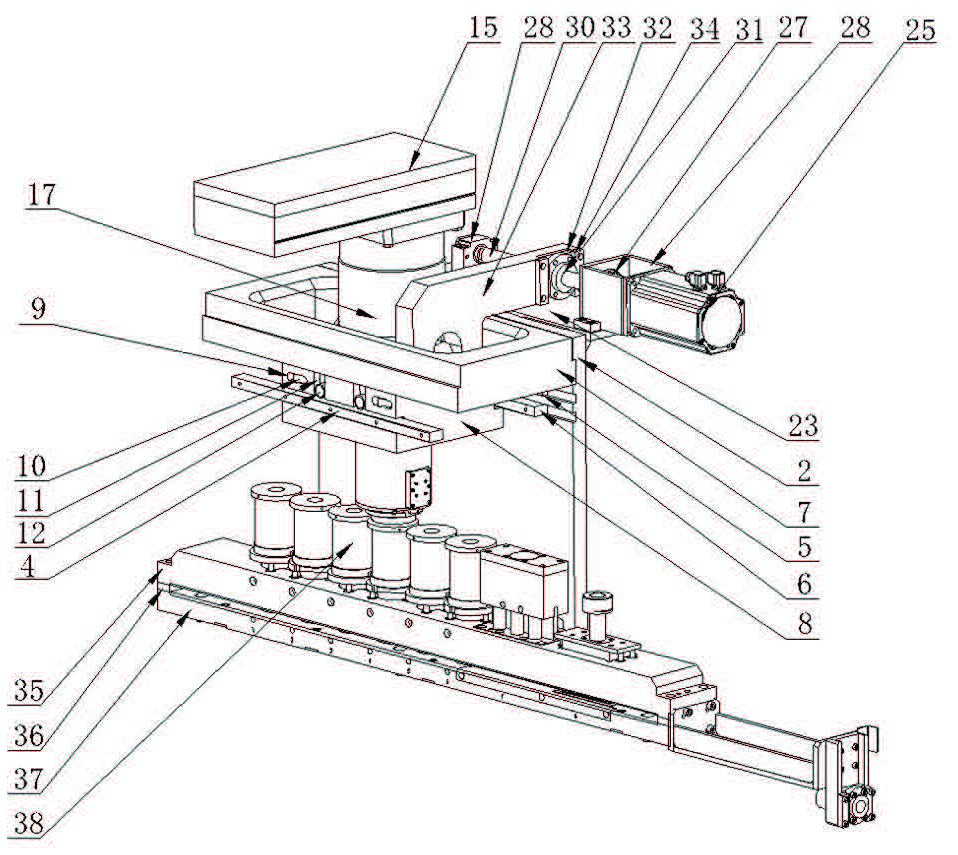

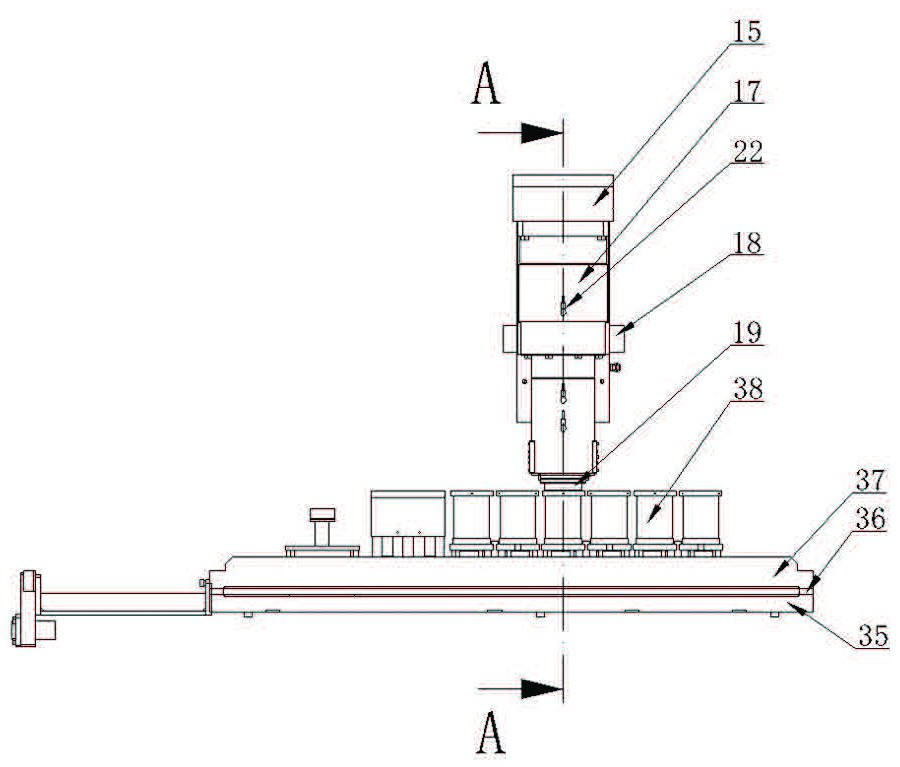

[0016] like Figures 1~6 The shown electric servo main drive busbar punching device includes a left frame 1 and a right frame 2. Both the left frame 1 and the right frame 2 are fixedly connected to the main engine of the bus punching machine, and the left frame 1 and the right frame are fixedly connected. A punching channel is formed between the racks 2, the left rack 1 and the right rack 2 are arranged oppositely, the inner surface of the left rack 1 is provided with a left positioning rail 3 and a left guide rail 4, and the inner surface of the right rack 2 is provided with a left positioning rail 3 and a left rail 4. The right positioning rail 5 and the right rail 6, the left rack 1 and the right rack 2 are slidably installed with a mounting plate 7 through the left rail 4 and the right rail 6, and a support 8 is arranged above the mounting plate 7. The two sides are fixedly connected with the left frame 1 and the right frame 2; the top of the left frame 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com