Milk product filling technology and apparatus thereof

A filling device and technology for dairy products, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of high energy consumption, high production cost, and many production links, and achieve low energy consumption, reduced energy consumption, and simplified The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

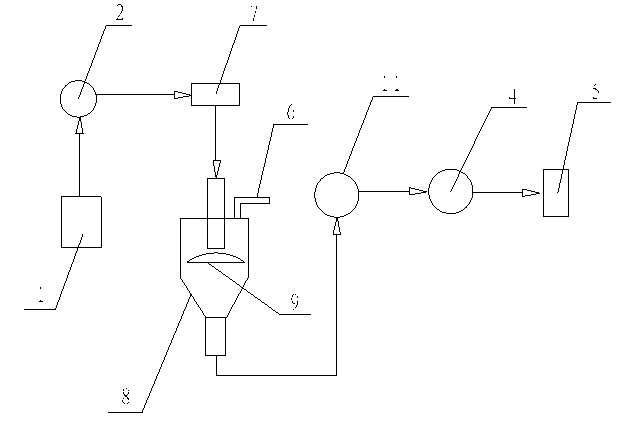

Image

Examples

Embodiment 1

[0025] A milk product filling process, comprising the following steps:

[0026] 1) Inject the milk to be filled into the degassing membrane degassing device at a pressure of 0.1Mpa for degassing treatment, and the vacuum pressure of the degassing membrane degassing device is -0.08Mpa;

[0027] 2) Pasteurize the degassed milk to be filled before filling.

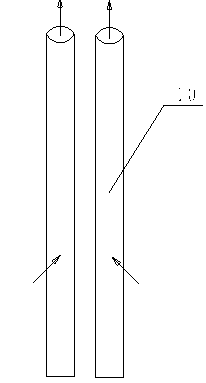

[0028] Step 1) The PP degassing membrane in the degassing membrane degassing device has an outer diameter of 0.3mm and a thickness of 0.05mm.

[0029] The shell of the degassing membrane degassing device is made of stainless steel.

[0030] The degassing membrane degassing device is packaged with epoxy resin that can withstand high temperatures of 50 ° C to 100 ° C.

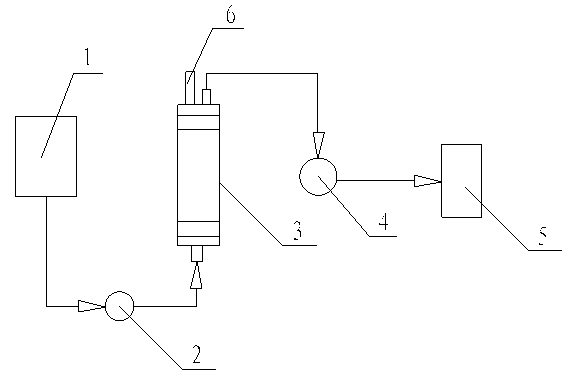

[0031] A dairy product filling device, such as figure 2 As shown, it includes a milk tank 1 and a booster pump 2 connected in sequence. The booster pump 2 is connected to the inlet of the degassing membrane degasser 3, and the outlet of the degassing membran...

Embodiment 2

[0035] A milk product filling device is the same as in Example 1, the difference is that the degassing membrane of the degassing membrane degassing device 3 is made of PTFE material, and the milk is injected into the degassing membrane at a pressure of 0.05Mpa to be degassed. The device is degassed, and the vacuum pressure of the degassing membrane degassing device is -0.09Mpa.

Embodiment 3

[0037] A milk product filling device is the same as in Example 1. The milk to be filled is injected into a degassing membrane degassing device at a pressure of 1 MPa for degassing treatment. The vacuuming pressure of the degassing membrane degassing device is -0.01 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com