Continuous hot-pressing sintering device and method for metal oxide evaporation target

A hot-pressing sintering and oxide technology, applied in cooking furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of unfavorable and precise control of the size of sintered products, large shrinkage of product diameters, and low production efficiency, and can avoid heating and cooling. Operation, saving sintering time, the effect of short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

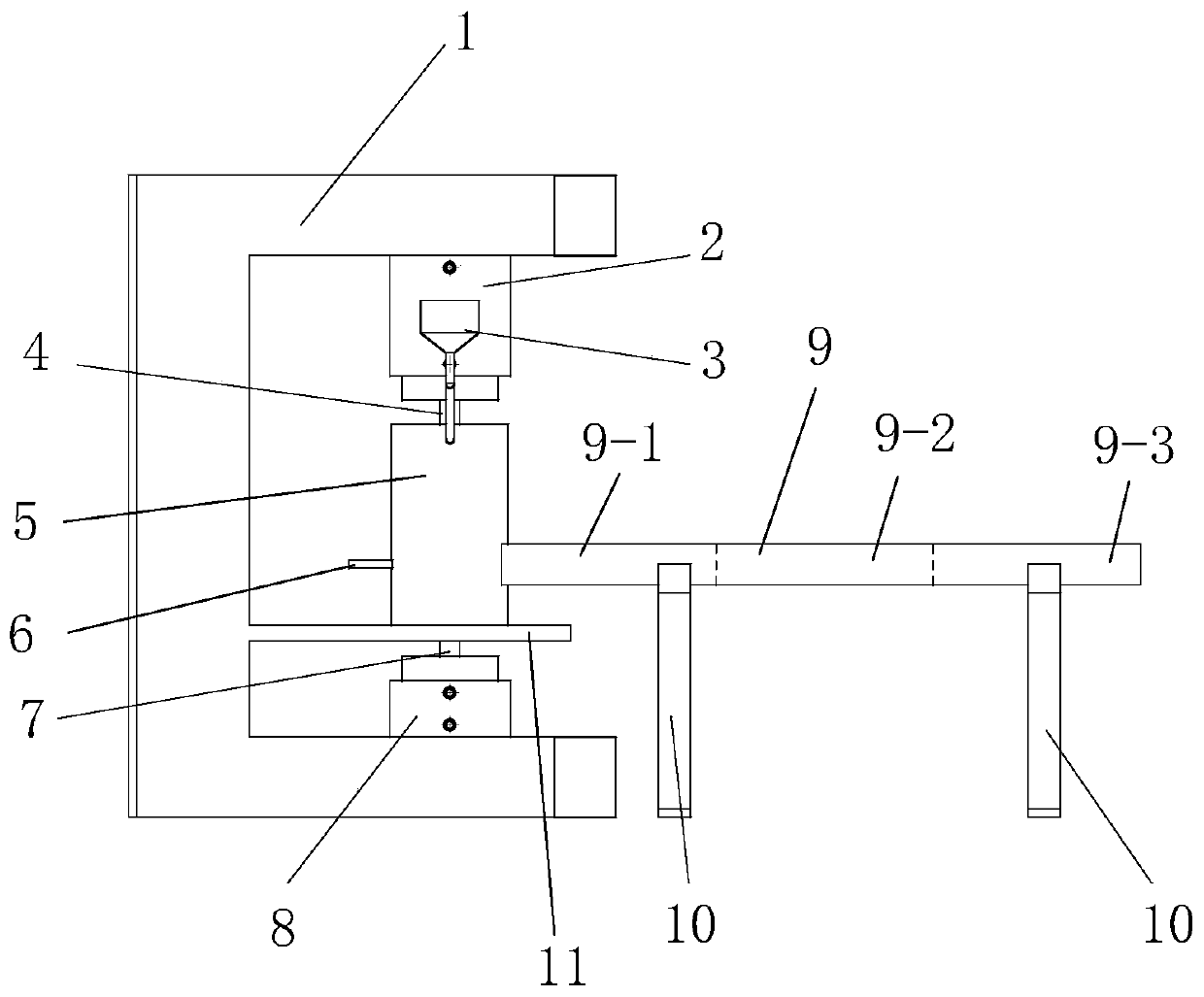

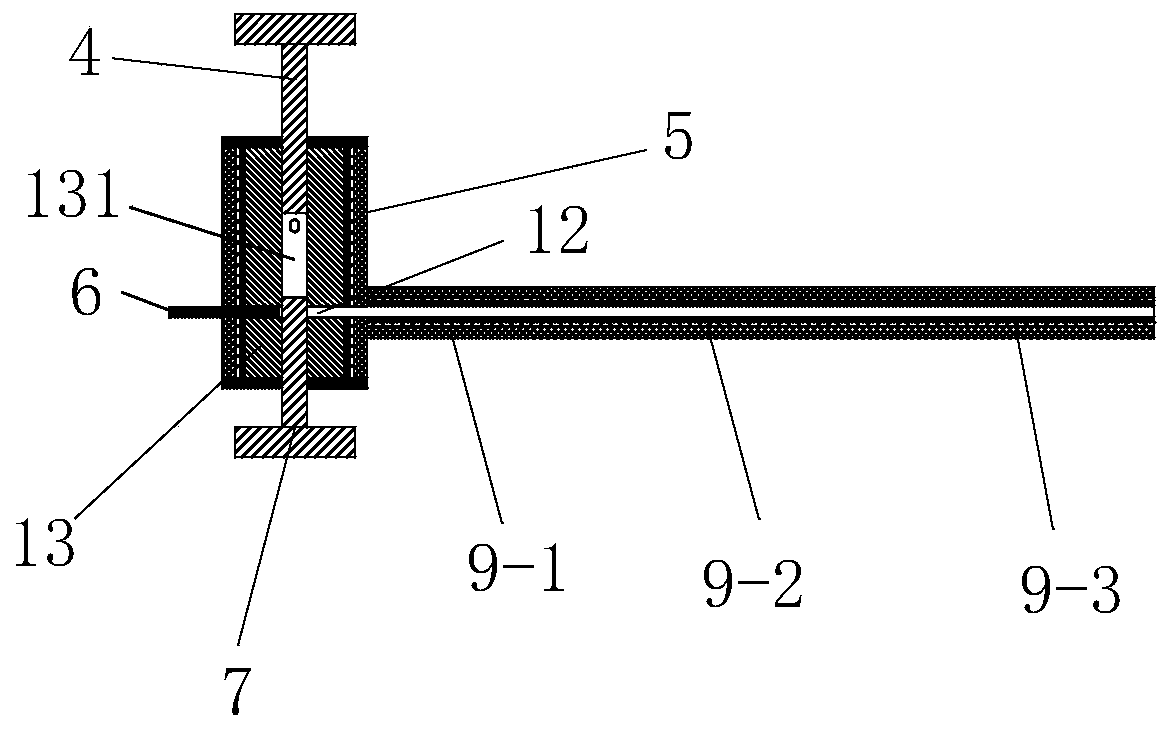

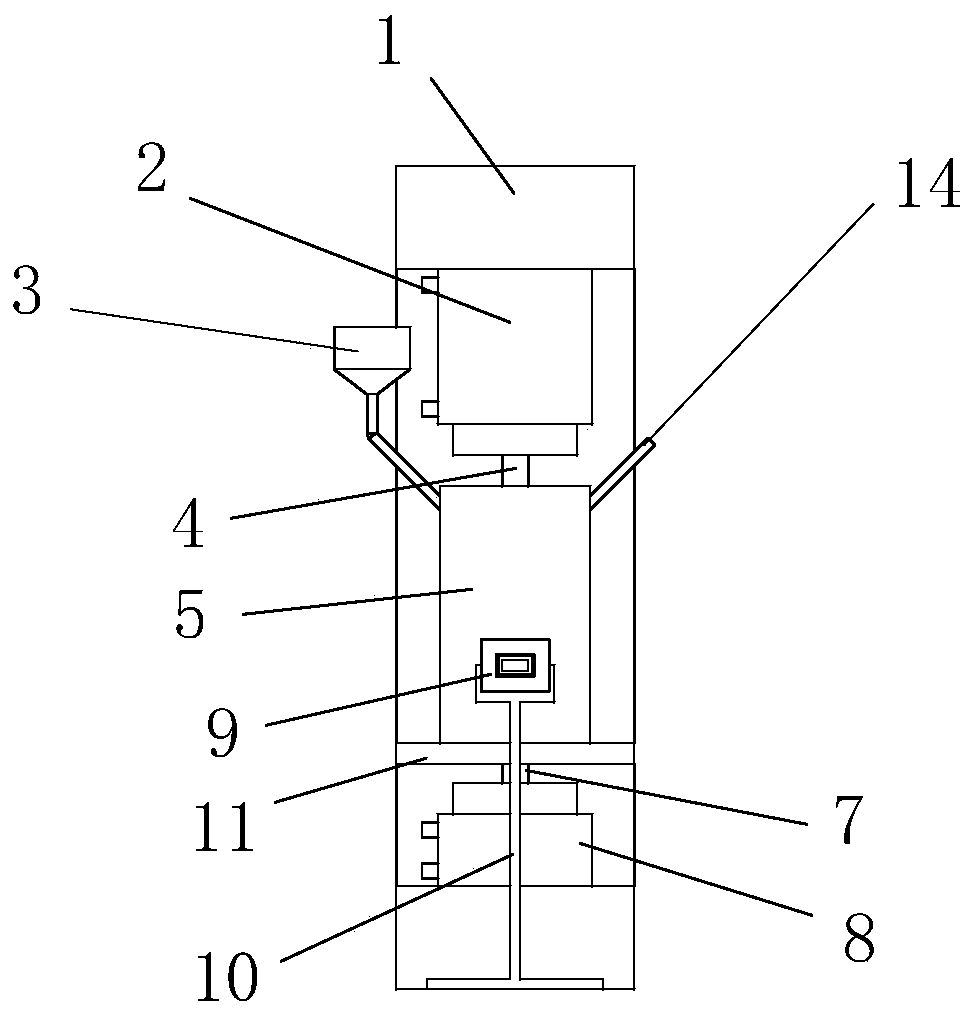

[0024] Example 1: A continuous hot-press sintering device for metal oxide evaporation targets, such as Figure 1-Figure 4 As shown, it includes a hydraulic machine frame 1, an upper hydraulic ram 2, a lower hydraulic ejector 8, a hot-press furnace body 5, a three-temperature section heat pipe 9 and a graphite mold 13 for target molding. The upper hydraulic ram 2 and the lower hydraulic ejector head 8 are respectively installed on the upper and lower ends of the hydraulic machine frame 1, the hot-press furnace body 5 is installed on the hydraulic machine frame 1 through the support plate 11, and the hot-press furnace body is located on the upper hydraulic pressure head 2 and the lower hydraulic pressure head. Between the heads 8, the graphite mold 13 is a cylinder with a target forming moving channel 131 in the middle, the graphite mold is installed in the hot press furnace body, and the upper hydraulic head is connected with a The graphite upper die rod 4 is connected with the...

Embodiment 2

[0028] Embodiment 2: A continuous hot-press sintering method for a metal oxide evaporation target, the device used is the continuous hot-press sintering device for a metal oxide evaporation target described in Example 1, comprising the following steps:

[0029] (1) Raise the temperature in the furnace cavity of the hot-pressing furnace body 5 to the sintering temperature of 1000°C and keep it constant;

[0030] ⑵Adjust the position of the graphite upper mold rod 4 and the graphite lower mold rod 7 through the upper hydraulic pressure head 2 and the lower hydraulic ejector head 8 to form the required mold cavity;

[0031] (3) Add a certain amount (21g) of powder through the powder inlet 3, and vacuum the mold cavity through the suction port 14. After the gas in the mold cavity and powder is discharged, the upper hydraulic pressure head drives the graphite upper mold rod to Move down and keep it in the required position for 10 minutes, so that the powder is sintered under pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com