Method for measuring iron content in kaolin through using spectrophotometer

A spectrophotometer and kaolin technology, applied in the measurement of color/spectral properties, etc., can solve the problems of high performance requirements and complicated steps of microwave digestion instruments, and achieve the effects of low equipment cost, simple operation and small sample volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Zhangzhou iron-stained kaolin was used as the sample. Its main mineral composition is kaolinite and a small amount of quartz, and its mineral structure is flake and a large number of tubes.

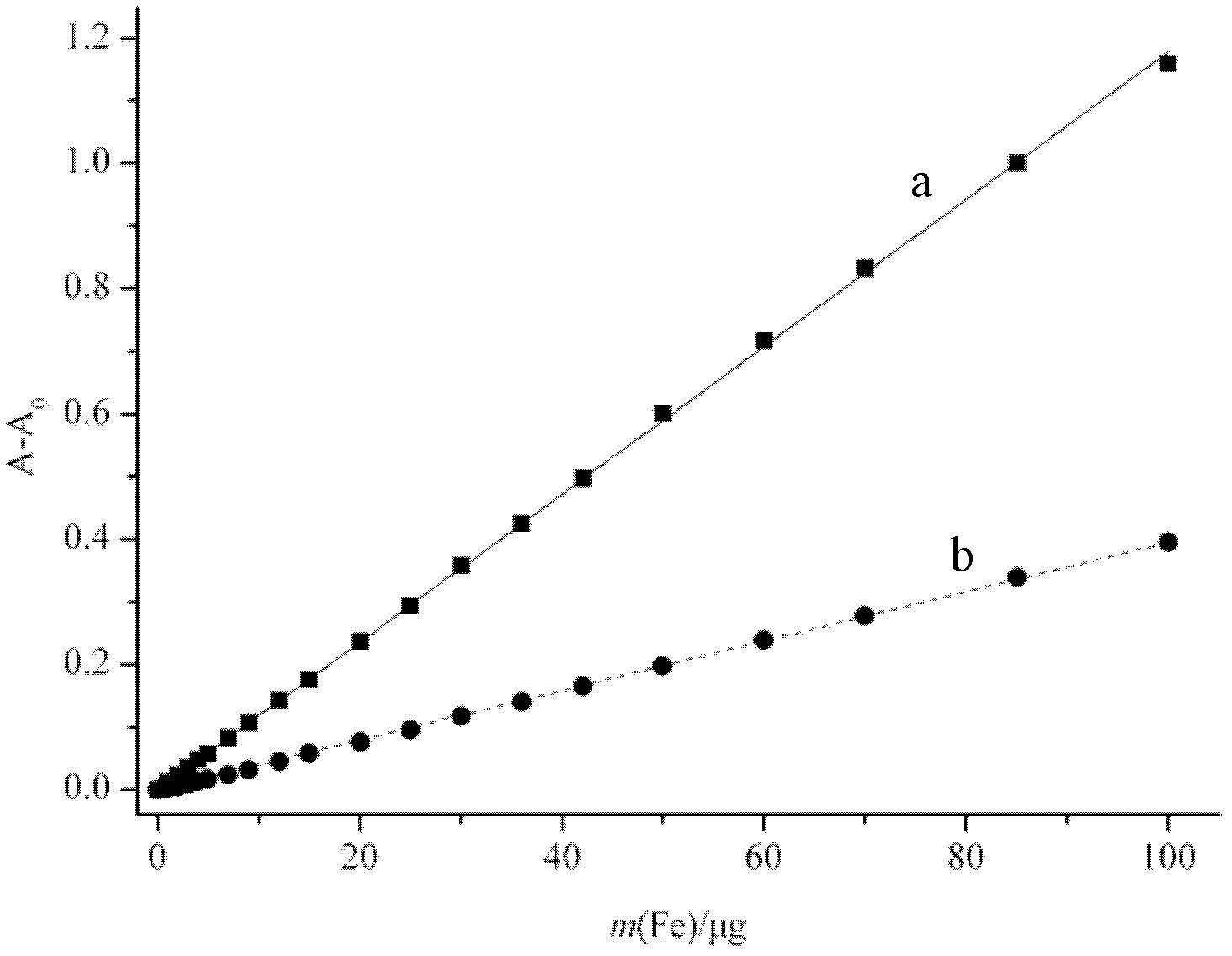

[0042] 2) Weigh 0.500g of kaolin sample, place it in a silver crucible paved with 2g of sodium hydroxide, add a few drops of absolute ethanol to wet the sample, and then cover the sample with a layer of 2.5g of sodium hydroxide , plus a crucible lid. The crucible is calcined in a high-temperature energy-saving electric furnace. The heating rate is 5°C / min, the calcination temperature is 650°C, the calcination time is 10min, and it is taken out for cooling. Clean the outside of the crucible, put it together with the cover into a 250mL beaker, soak the frit with boiling water, wash the crucible and the crucible cover with hot water and a broom, and add 25mL of concentrated hydrochloric acid to dissolve all the precipitate under constant stirring. Cool to room temperature, trans...

Embodiment 2

[0046] The analysis and testing process is the same as in Example 1. The sample is bleached Zhangzhou iron dyed kaolin. When melting the sample, the heating rate is 7.5°C / min, the calcination temperature is 600°C, and the calcination time is 20min. The volume of the time-shifted sample solution is 5mL. When using a 3cm absorption dish, the absorbance of the measured sample solution is A=0.614, and the absorbance of the blank is A 0 =0.042, the calculated iron content in kaolin is 0.485%. When using a 1cm absorption dish, the absorbance of the measured sample solution is A=0.237, and the absorbance of the blank is A 0 =0.045, the calculated iron content in kaolin is 0.486%. The two are basically close to the iron content (0.50%) determined by the EDTA complexometric titration method in the national standard GB / T 14563-2008.

Embodiment 3

[0048] The analysis and testing process is the same as in Example 1. The sample is Zhangzhou iron-dyed kaolin calcined at 980°C. When melting the sample, the heating rate is 10°C / min, the calcination temperature is 625°C, and the calcination time is 15min. The volume of the time-shifted sample solution is 2mL. When using a 3cm absorption dish, the absorbance of the measured sample solution is A=0.392, and the absorbance of the blank is A 0 =0.042, the calculated iron content in kaolin is 0.742%. When using a 1cm absorption dish, the absorbance of the measured sample solution is A=0.163, and the absorbance of the blank is A 0 =0.045, the calculated iron content in kaolin is 0.747%. The two are basically close to the iron content (0.74%) determined by the EDTA complexometric titration method in the national standard GB / T 14563-2008.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com