Direct reduction iron hot-charging method by use of chain conveyer

A technology of reducing iron and chain bucket machine, applied in the direction of fluidized bed furnace, etc., can solve the problems of large investment and operating costs, and achieve the effects of convenient equipment maintenance, less energy consumption, and reduced temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

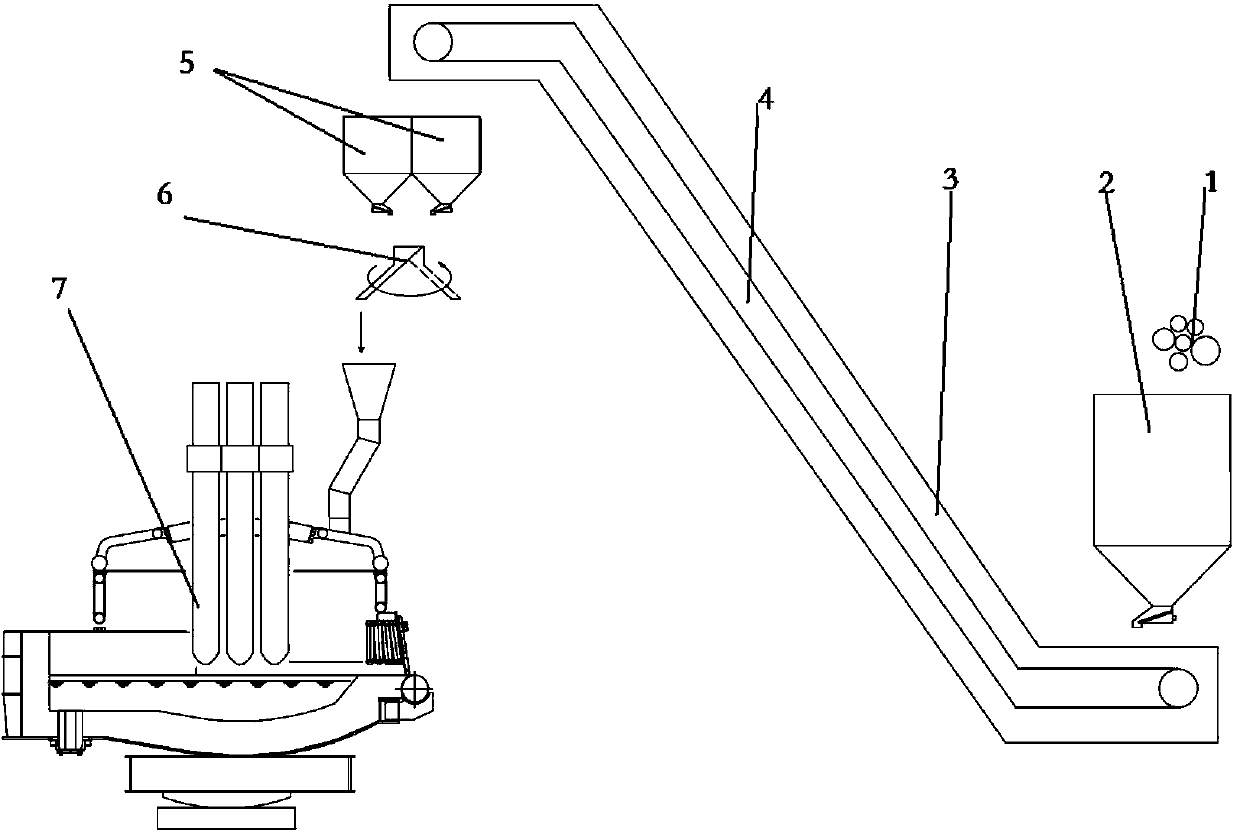

[0013] figure 1 It is a specific embodiment of the present invention.

[0014] 1. The hot direct reduced iron 1 with a temperature above 600°C is discharged into the storage tank 2;

[0015] 2. The storage tank 2 unloads the hot direct reduced iron 1 into the chain bucket machine 4;

[0016] 3. The chain bucket machine 4 transports the hot direct reduced iron 1 to the electric furnace workshop, and unloads it into the furnace top transition tank 5;

[0017] 4. The feeding chute 6 is rotated to the feeding position, and the furnace top transition material tank 5 loads the hot direct reduced iron 1 into the electric furnace 7 through the feeding chute 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com