Rapid-melted copolyester hot melt glue and preparation method thereof

A technology of copolyester and hot-melt adhesives, which is applied in the direction of adhesives, etc., can solve problems that affect the bonding performance of hot-melt adhesive products and are not clear, and achieve the effects of shortening melting time, improving production efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

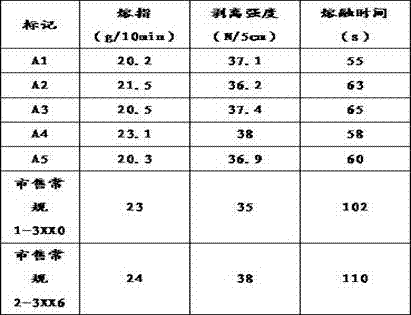

Examples

Embodiment 1

[0017] A fast-melting copolyester hot-melt adhesive, the composition of the dibasic acid in its main material is: 166g of terephthalic acid, 49.8g of isophthalic acid, 43.8g of 1,6-adipic acid; The composition of the diol is: 105.3g of 1,4-butanediol, 14.26g of ethylene glycol, 86.92g of diethylene glycol, and 21.24g of 1,6-hexanediol; among its auxiliary materials, the addition of tetrabutyl titanate The amount is 0.26g, and the addition amount of triphenyl phosphite is 0.65g.

[0018] The preparation method of the copolyester hot-melt adhesive of above-mentioned fast melting, step is as follows:

[0019] (1) Add the above-mentioned dibasic acid, dibasic alcohol and catalyst into a 1L reactor for esterification reaction, start stirring, and gradually raise the temperature to 160°C. At this time, water begins to distill, and continue to gradually raise the temperature to 210°C. When the water output reaches 95% or more of the theoretical value, the esterification reaction end...

Embodiment 2

[0023] A fast-melting copolyester hot-melt adhesive, the composition of the dibasic acid in its main material is: 166g of terephthalic acid, 66.4g of isophthalic acid, 21.9g of 1,6-adipic acid; The composition of the diol is: 97.2g of 1,4-butanediol, 26.66g of ethylene glycol, 57.24g of diethylene glycol, and 31.86g of 1,6-hexanediol; among its auxiliary materials, the addition of tetrabutyl titanate The amount is 0.25g, and the addition amount of triphenyl phosphite is 0.76g.

[0024] The preparation steps of the fast-melting copolyester hot-melt adhesive described in Example 2 are the same as in Example 1, and the resulting product prepared in Example 2 is marked as A2.

Embodiment 3

[0026] A fast-melting copolyester hot-melt adhesive, the composition of the dibasic acid in its main material is: 166g of terephthalic acid, 49.8g of isophthalic acid, 29.2g of 1,6-adipic acid; The composition of the diol is: 96.3g of 1,4-butanediol, 19.84g of ethylene glycol, 67.84g of diethylene glycol, and 24.78g of 1,6-hexanediol; among its auxiliary materials, the addition of tetrabutyl titanate The amount is 0.12g, and the addition amount of triphenyl phosphite is 0.61g.

[0027] The preparation steps of the fast-melting copolyester hot-melt adhesive described in Example 3 are the same as in Example 1, and the resulting product prepared in Example 3 is marked as A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com