Precast piece for busbar of storage battery and method for welding same with polar plates of storage battery

A battery and busbar technology, applied in battery pack parts, electrical components, welding equipment, etc., can solve the problems of easy corrosion, loose welding surface of tabs, long welding time, etc., to ensure quality, prolong service life, The effect of reducing the chance of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

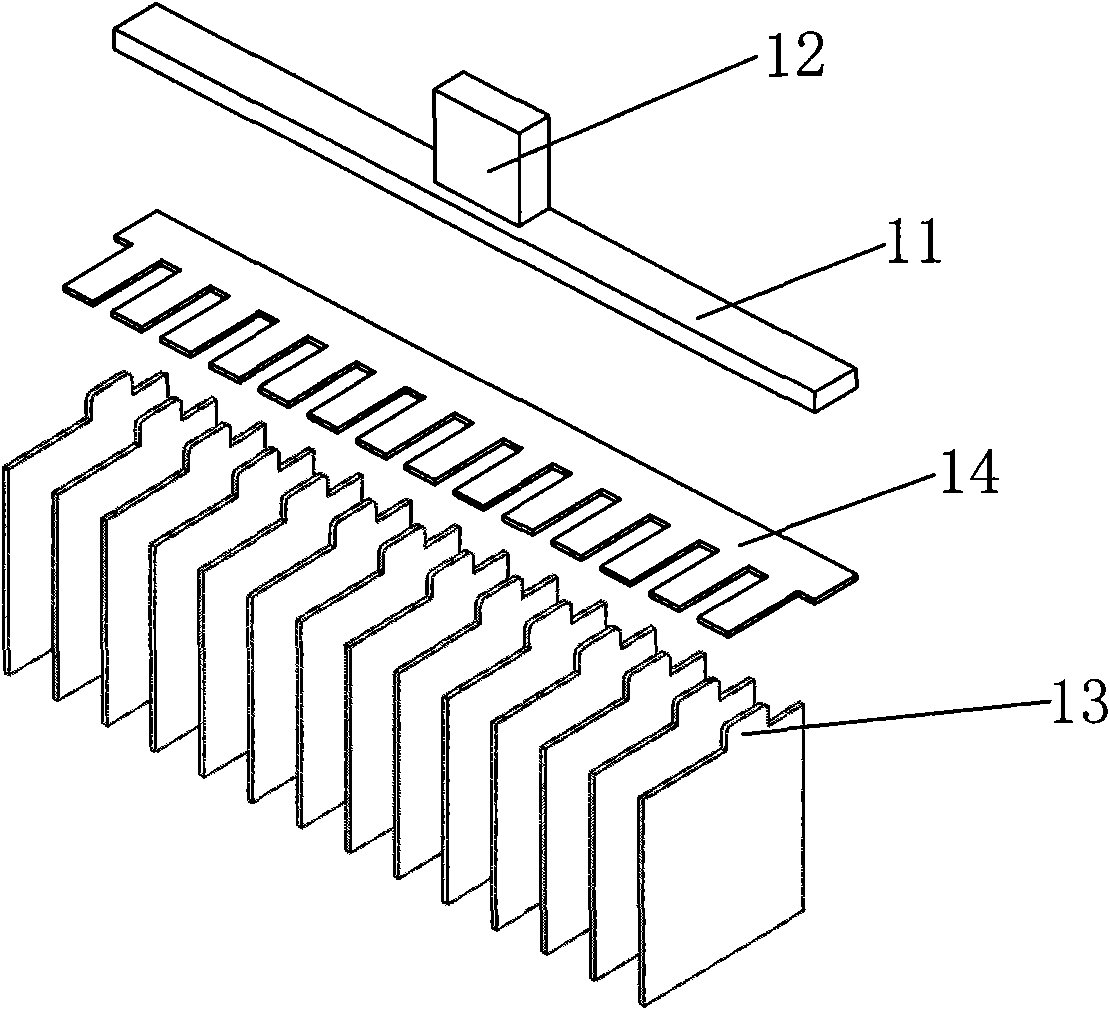

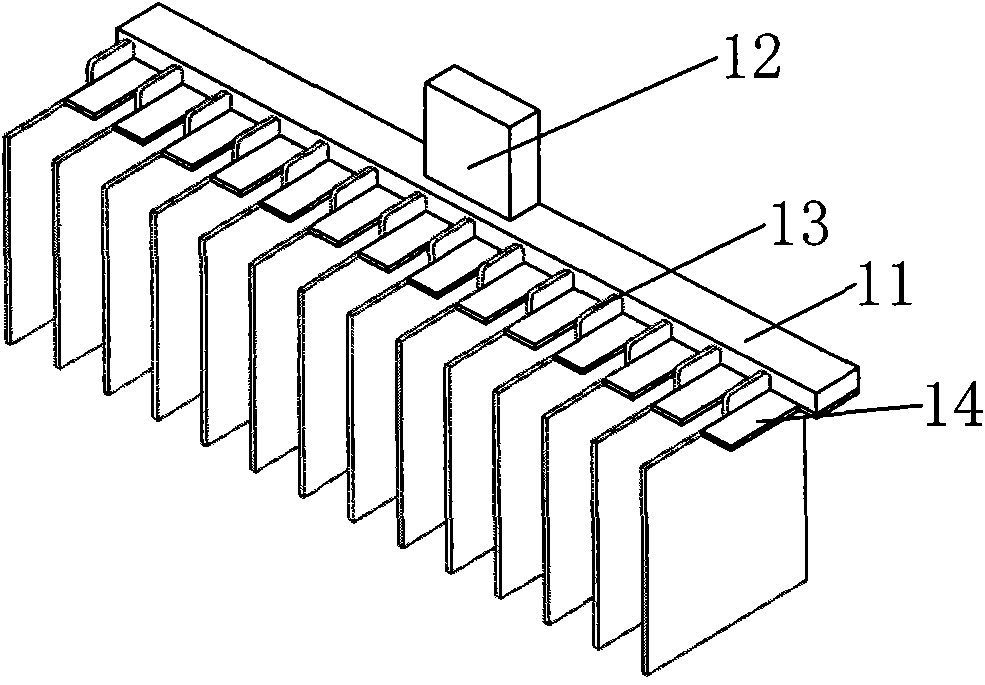

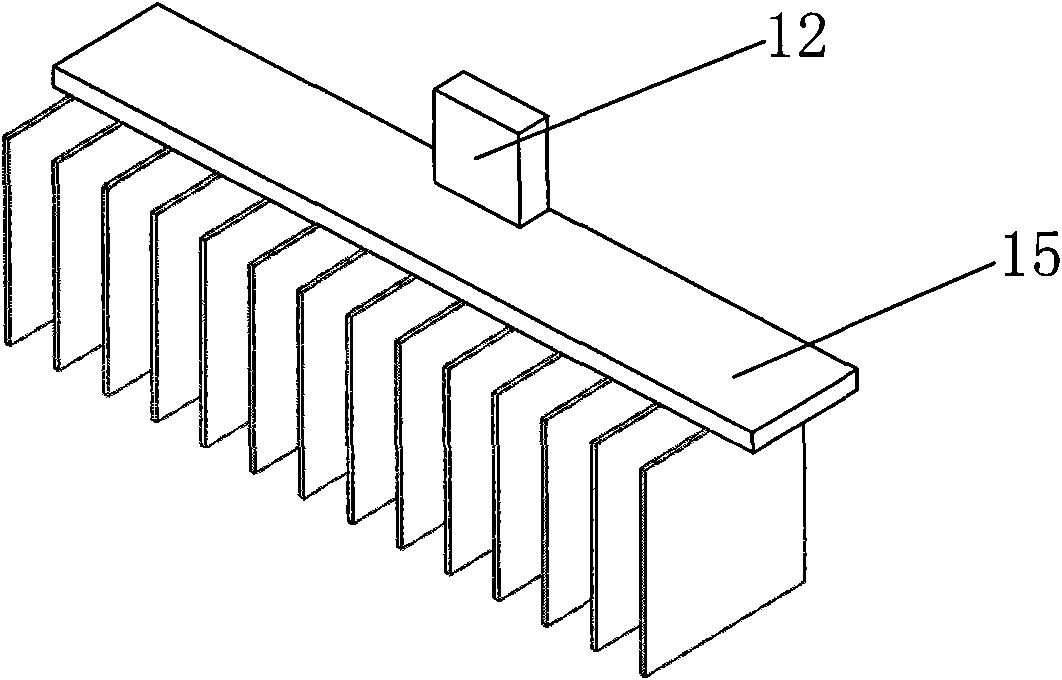

[0025] like Figure 4 , 5 As shown, the large-capacity bus precast of the present invention is composed of a strip-shaped connecting main board 21 and a copper core pole 22 that is cast on the connecting main board and is perpendicular to the connecting main board, and extends along the side of the longer side of the connecting main board. Comb-shaped spare tooth bar 211, the cross-section of this spare tooth bar is semicircular, its bottom surface 212 is flat with the bottom surface of the precast part connected to the main board, and the apex of the arc surface is slightly lower than the top surface of the precast part connected to the main board. The width of the bottom surface of the bar is equivalent to the width of the welding frame tooth plate 24, and the gap between the two comb-shaped stock tooth bars equals the width of the welding frame tooth plate groove; One side of the connecting mainboard shrinks from the middle to both ends, forming two slopes 213. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com