High binding force nano-amorphous sprayed welding wire

A nano-amorphous, bonding force technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of low bonding force, high cost, weak stability, etc., achieve high bonding force, reduce melting time, the effect of prolonging the molten state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

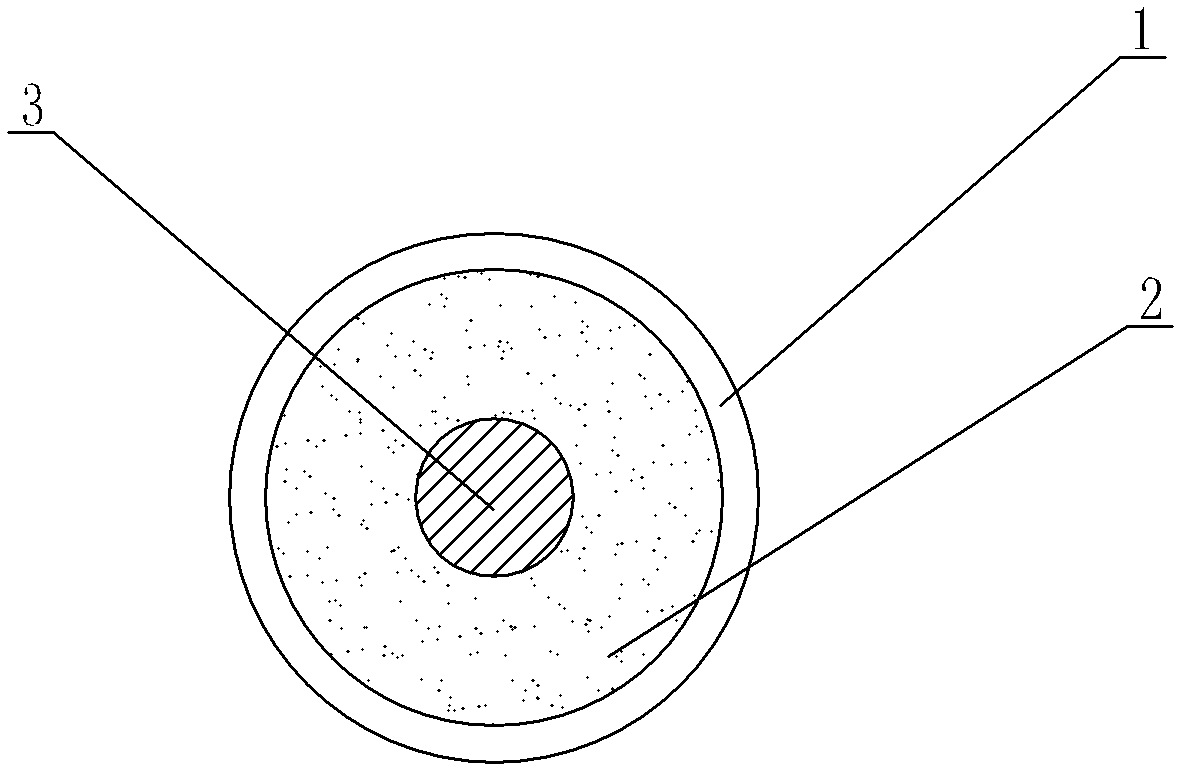

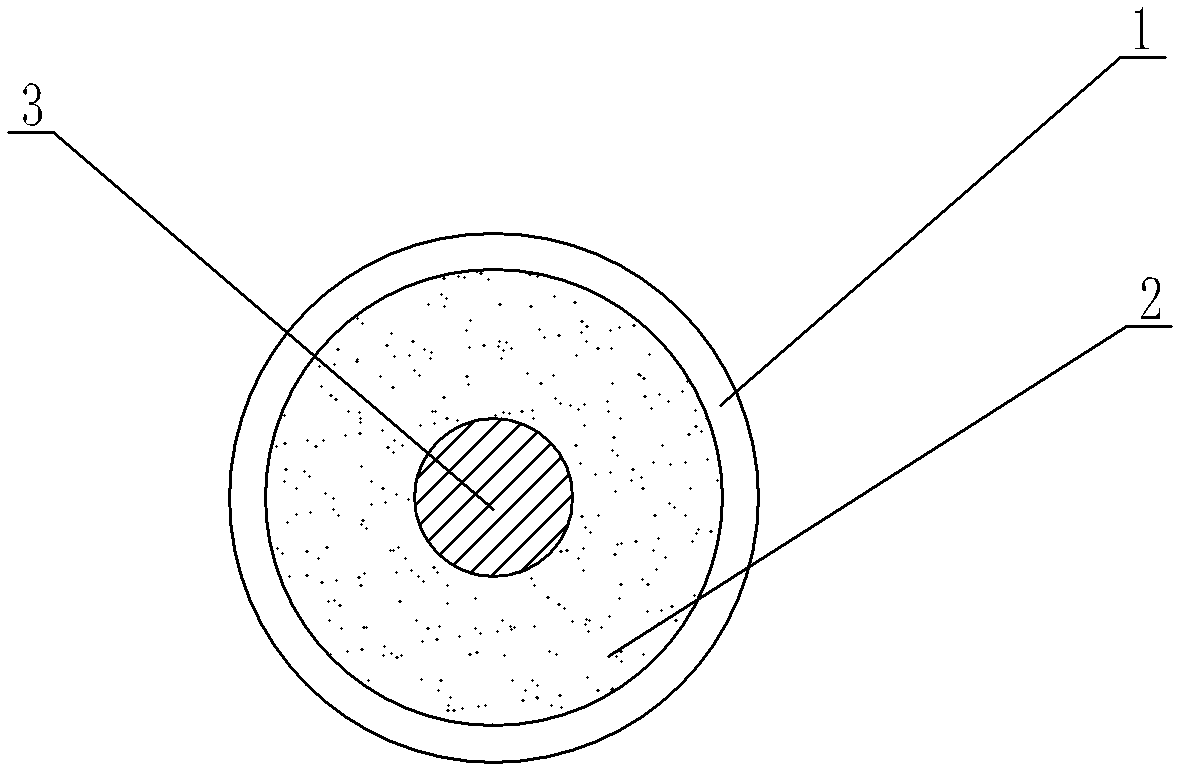

[0017] Embodiment 1: The strip matrix 1 is an iron-based strip, the iron-based strip is made of low-carbon steel, the filling powder is a mixture of ferroboron, ferro-tungsten, and ferroniobium, and the central welding wire is aluminum welding wire .

Embodiment 2

[0018] Embodiment 2: The strip matrix is a nickel-based strip, the nickel-based strip is made of pure nickel, and the filling powder is ferronium, ferrotungsten, niobium powder, iron powder, chromium powder, nickel powder, molybdenum powder , carbon powder, ferromolybdenum, tungsten carbide, ferrochrome powder and a mixture of ferronickel, and the central welding wire is aluminum-magnesium welding wire.

Embodiment 3

[0019] Embodiment 3: the strip matrix is an iron-based strip, the iron-based strip is made of austenitic ferritic stainless steel, and the filling powder is ferronium, tungsten powder, ferroniobium, chromium powder, nickel powder, A mixture of molybdenum powder, carbon powder, ferromolybdenum, and tungsten carbide, and the central welding wire is an aluminum-silicon welding wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com