Micro-jet-flow water-cooling system for luminuous diode LED

A light-emitting diode and cooling system technology, which is applied in the cooling/heating device, cooling/ventilation/heating transformation of lighting devices, lighting devices, etc., can solve the problems of not being able to meet the temperature requirements of LEDs, and achieve large heat transfer coefficients and flexible control , Good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

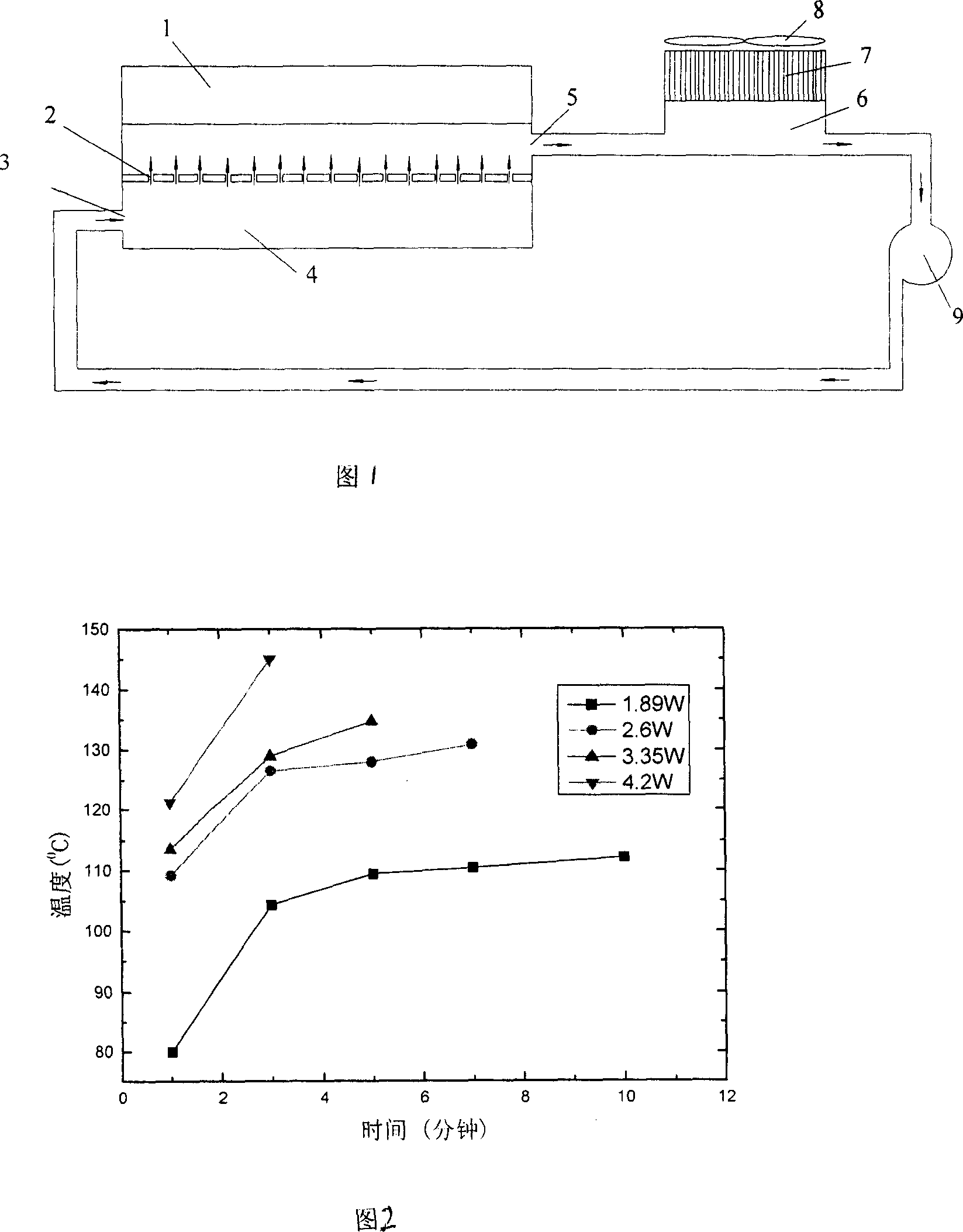

[0017] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0018] The lower surface of the base 1 of the LED chip is installed on the shell of the micro jet, and the micro jet is made of carbon nanotubes, high thermal conductivity metal, diamond and other high thermal conductivity materials. The outer surface of the micro jet is connected with the lower surface of the base 1 of the LED chip by using heat conduction paste to increase the heat conduction effect. A cavity 4 is provided in the micro-jet, and the middle of the micro-jet cavity 4 is divided into upper and lower two monomers 10, 12 by a partition plate 2 with a plurality of micro-spouts. The micro-jet adopts Carbon nanotubes, high thermal conductivity metals, diamonds and other high thermal conductivity materials. Both sides of the cavity 4 are respectively provided with a cooling water inlet 3 and a cooling water outlet 5, the cooling water inlet 3 is co...

Embodiment 2

[0022] Embodiment 2 is the same as Embodiment 1, except that Embodiment 1 adopts the middle of the micro-jet fluidizer cavity to be divided into upper and lower two monomers 10, 12 by a partition plate 2 with a plurality of micro-orifices. And embodiment 2 is divided into upper, middle and lower three monomers 10, 11, 12 by two partitions 2 with a plurality of micro nozzles. This design is mainly to cool the double-sided LED chipset. See Figure 5. In the figure, the cooling water flows in from the inlet 3 and enters the middle monomer 11 of the micro-jet cavity. Under the action of pressure, the cooling water forms jets at the nozzles 2 on both sides respectively, and impacts on the base 1 of the LED chip. On the inner side of the contact surface of the micro-jet fluidizers whose lower surfaces are closely connected, the cooling water after heat exchange respectively flows out from the lower monomer 12 and the upper monomer 10 and joins at the outlet 5, and re-enters the main...

Embodiment 3

[0024] Embodiment 3 is the same as Embodiment 2, except that in Embodiment 3, the cold plate 18 etched with microchannels is directly installed inside the water tank 6 . When the heated water flows in from the water tank inlet 14, after flowing to the cold plate 18 etched with microchannels, it will be divided into many streams of small fluids, and then flow out from the water tank outlet 15 confluence. Due to the use of micro-channels, the heat transfer coefficient will be greatly enhanced, and the heat in the water will be quickly transferred to the water tank. After the cooling effect of the heat sink and the fan, the heat will be diffused to the environment as soon as possible. See Figure 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com