Forced heat exchange tube

A technology that enhances heat exchange and heat exchange tubes. It is applied to tubular elements, heat exchange equipment, lighting and heating equipment, etc. It can solve the problems of heat transfer performance degradation, poor synergy between speed and temperature gradient, etc., and achieve increased heat transfer. Heat area, effect of improving heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

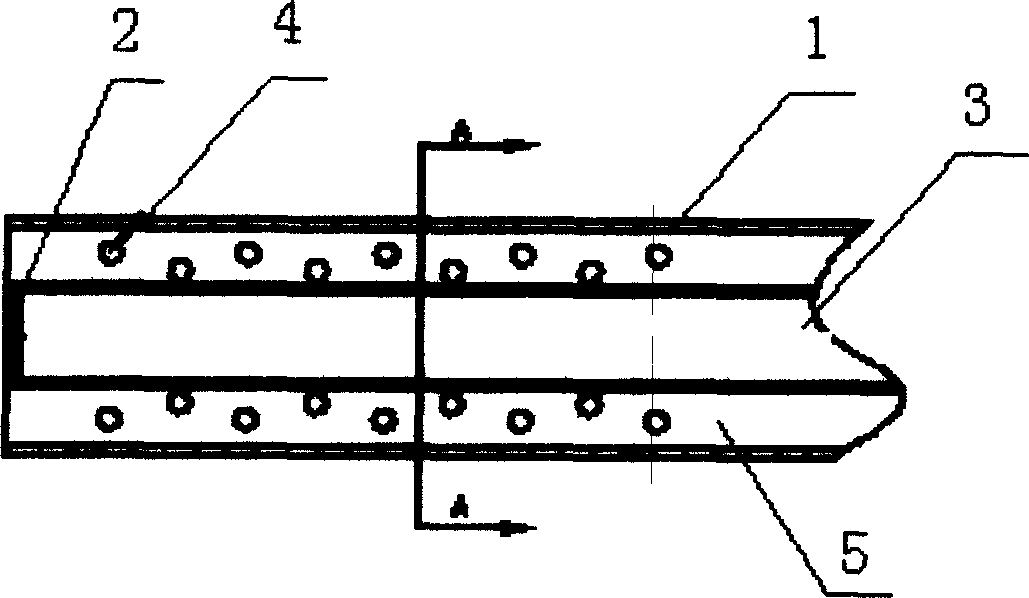

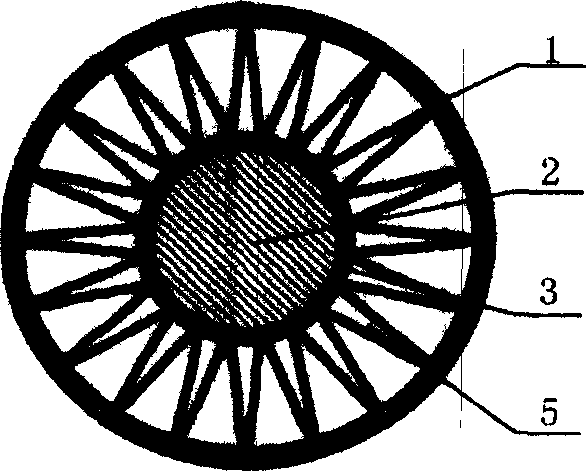

[0012] see figure 1 , 2. The present invention includes an external base pipe 1, an internal core pipe 3 with both ends plugged 2, and 2 to 30 corrugated fins 5 uniformly arranged along the circumference of the internal core pipe 3. On the side of the corrugated fins 5 There are through holes 4 on the wall. Since the through holes 4 are opened on the corrugated fins 5 , the flow channel is an incompletely separated annular channel, and the perforated corrugated fin runs through the entire flow channel in the annular flow tube.

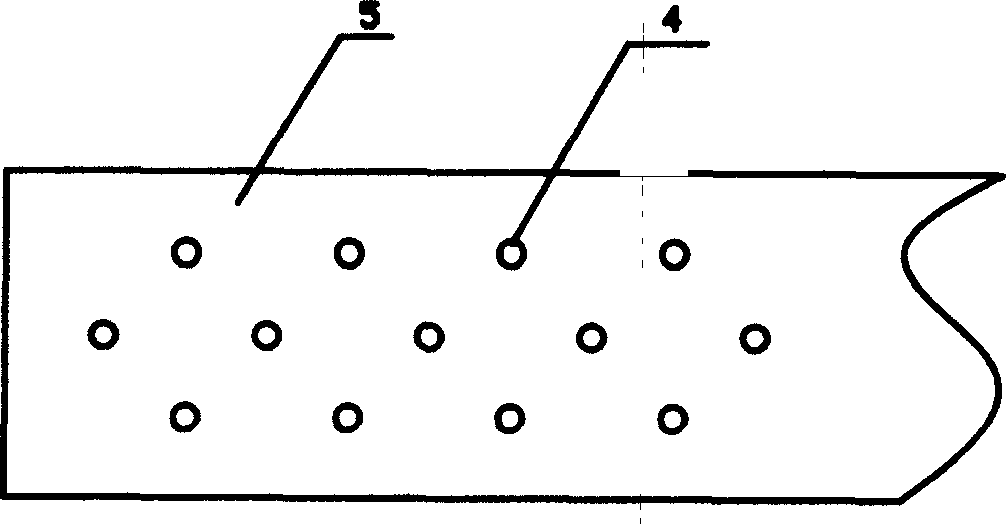

[0013] see image 3 According to the present invention, the corrugated fins 5 are provided with through holes 4 with a hole pitch of 10 mm and a diameter of 3 mm.

[0014] The corrugated fin 5 of the present invention adopts a straight edge, which is convenient to manufacture, and the gas flow resistance will not increase significan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com