Precision thermostatic control laboratory box

A technology of constant temperature control and constant temperature controller, which is applied in the direction of using electric means for temperature control, electric controller, controller with specific characteristics, etc., can solve the problems of publicity and no specific structure, and reduce breakdown damage. , Good thermal insulation effect, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

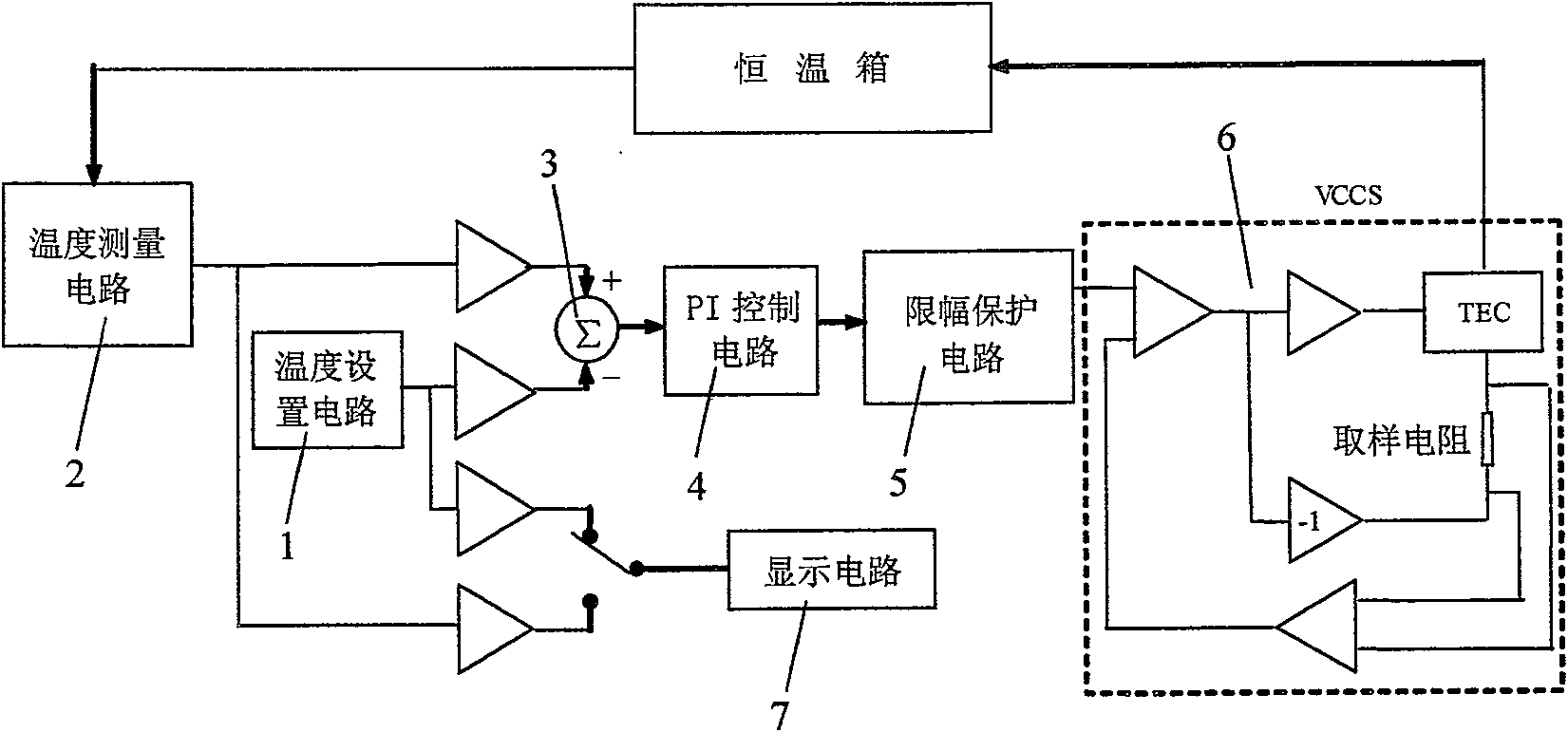

[0057] Embodiment 1 The general structure of the present invention is described with reference to the accompanying drawings

[0058] The precise constant temperature control box of the present invention can be divided into two parts: a constant temperature box and a constant temperature controller.

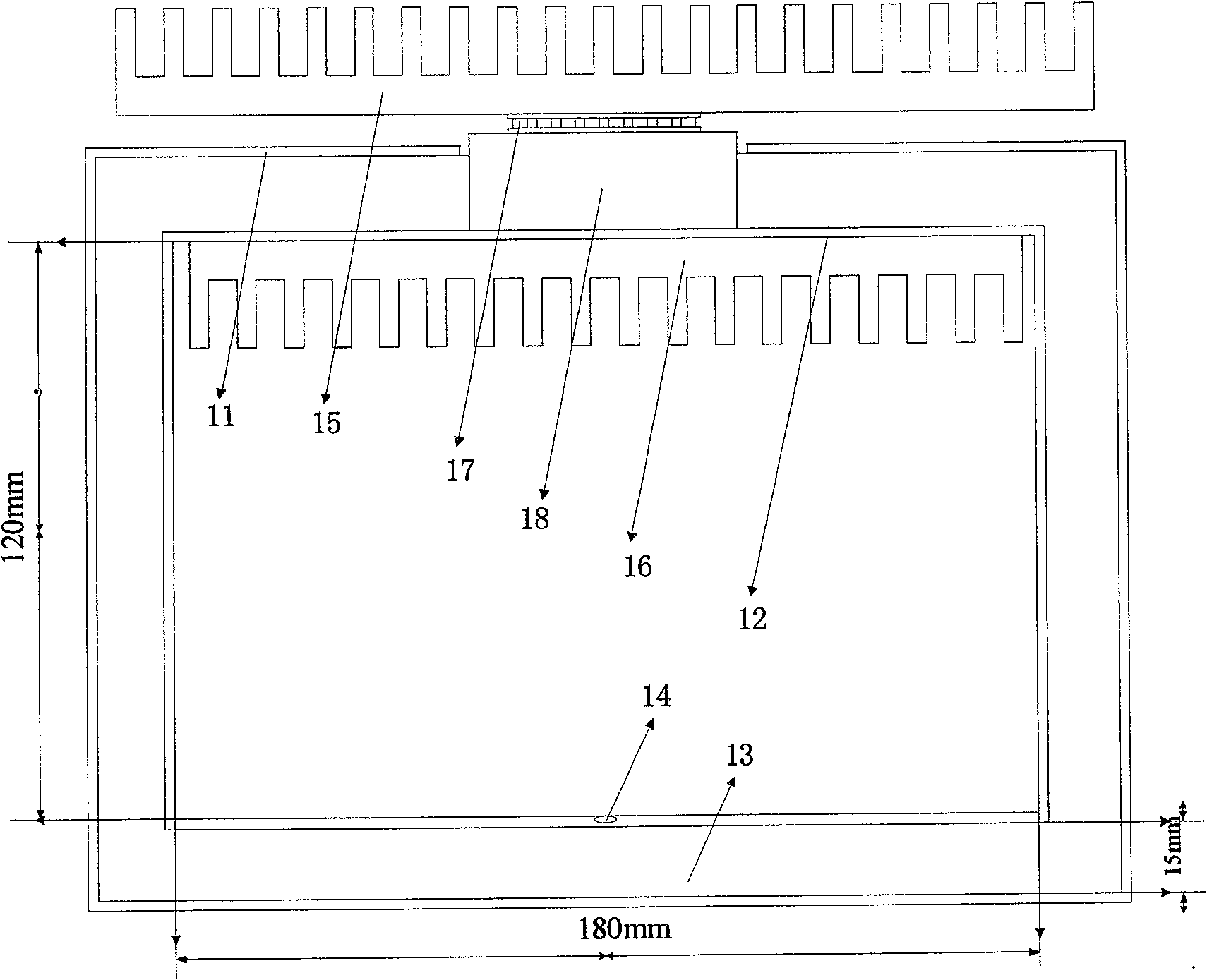

[0059] The incubator includes a heat preservation part member and a heat transfer part member.

[0060] The function of the insulation part is to make the heat transferred by the heat transfer part return to the external environment as little as possible. like figure 2 As shown, the components of the thermal insulation part of the incubator are as follows: the outer shell (11) of the box is designed with stainless steel, which ensures the strength of the entire box. In order to keep the air temperature in the box as consistent as possible, aluminum with better thermal conductivity is used as the material of the inner tank (12). The thermal insulation layer (13) is made of poly...

Embodiment 2

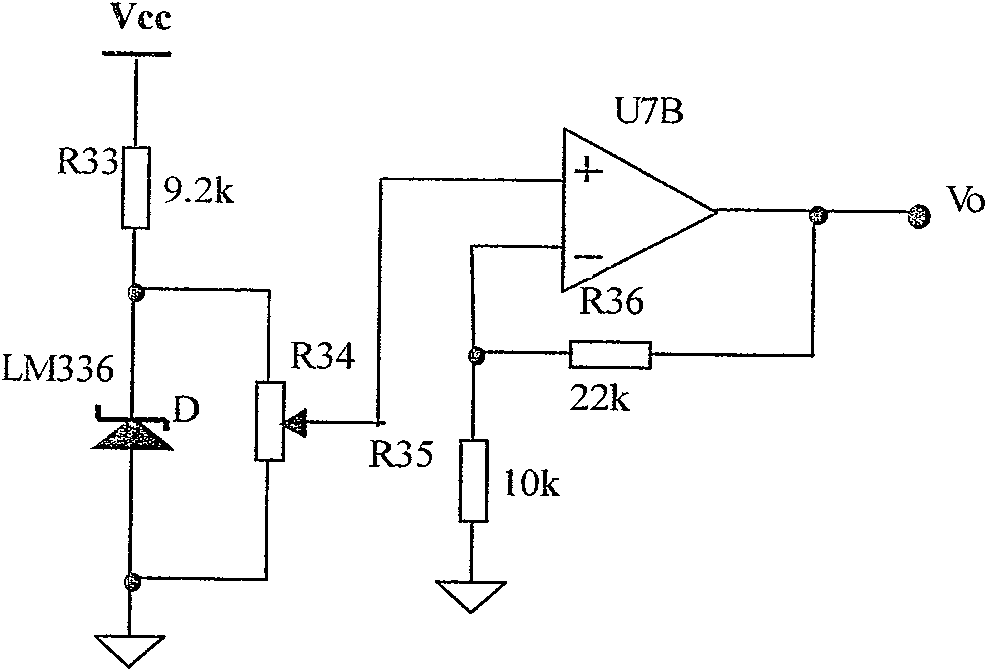

[0065] Embodiment 2 The circuit structure of the thermostatic controller is described with reference to the accompanying drawings

[0066] like image 3 As shown, the temperature setting circuit (1) of the thermostatic controller includes: an external DC power supply (Vcc) is connected to a 9.1k resistor and then a precision voltage reference module (LM336) is grounded; LM336 is connected to a 10k potentiometer in parallel, and its tap It is connected to the non-inverting input terminal of the operational amplifier U7B; the inverting input terminal of the operational amplifier U7B is connected to a 10k resistor to ground, and then a 22k resistor is connected to the U7B output. In addition, in order to improve the driving ability, a voltage follower composed of U2B is added to the output end of U7B. The non-inverting input end of U2B is connected to the output end of U7B, and the inverting input end of U2B is connected to its output end.

[0067] like Figure 4 As shown, the ...

Embodiment 3

[0073] Embodiment 3 Design of PID control system of the present invention

[0074] The constant temperature controller part of the constant temperature control experiment box is obtained by changing the PID control parameters. The method for determining this parameter is as follows:

[0075] Because the whole system involves many links, it is inconvenient to directly analyze it in the time domain, so it is necessary to establish the model of the system in the S domain. The open-loop transfer function of the system consists of two parts: the PID control system transfer function and the controlled system transfer function, namely G(s)=G 1 (s) · G 2 (s), and because C(s)=G(s)·[R(s)-C(s)], the system closed-loop transfer function is:

[0076] C ( s ) R ( s ) = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com