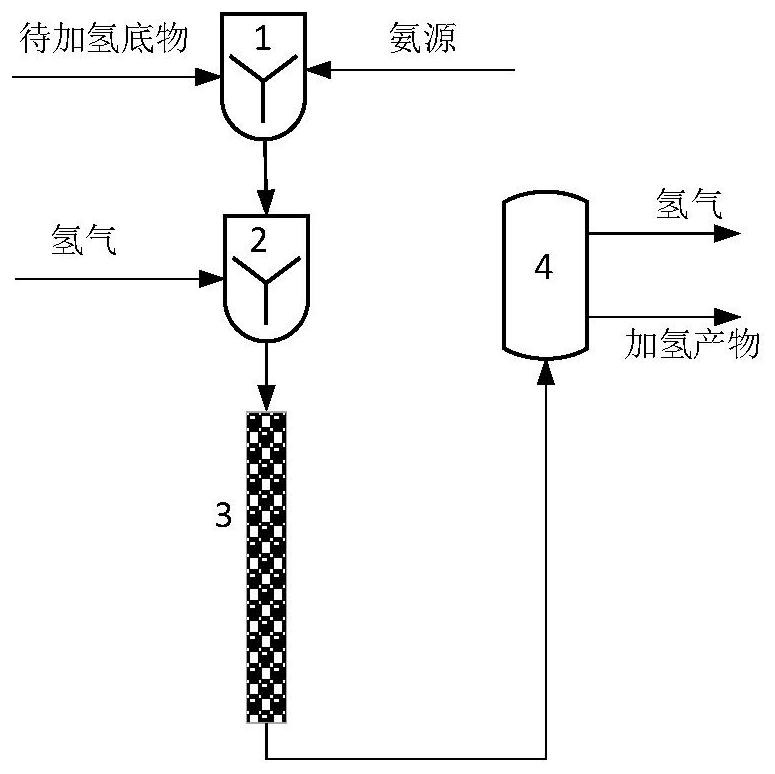

A device for continuously synthesizing benzylamines by heterogeneous hydrogenation in a microreactor

A micro-reactor, benzylamine technology, applied in the field of chemical reactions, can solve the problems of poor control accuracy of process conditions, large catalyst dosage, large reactor volume, etc., to avoid local excessive hydrogenation, reduce by-products, and transmit high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Carry out experiment according to this method, configure the ethyl acetate solution of benzaldehyde, concentration is 5wt%, mixes with ammonia gas in inlet film dispersion micro-mixer 1, the molar ratio of control ammonia / benzaldehyde is 15:1, mixes with hydrogen afterwards Mix in the entrance film dispersion micro-mixer 2, the formed gas-liquid mixture passes through the micro-packed bed reactor filled with Raney nickel catalyst, the control reaction temperature is 150°C, the pressure is 5.0MPa, and the control residence time is 0.5min. Gas-liquid phase separation was carried out at the outlet of the packed bed, and the obtained ethyl acetate solution was analyzed. The conversion rate of the reaction was 100%, and the yield of benzylamine was 96%.

Embodiment 2

[0034] Carry out experiment according to this method, configure the methanol solution of benzaldehyde, concentration is 10wt%, mixes with ammonia in inlet micro-sieve micro-mixer 1, the molar ratio of control ammonia / benzaldehyde is 0.5:1, then mixes with hydrogen in Mix in the inlet micro-sieve micro-mixer 2, and the formed gas-liquid mixture passes through the micro-packed bed reactor filled with palladium-carbon catalyst. The reaction temperature is controlled to be 100°C, the pressure is 10.0MPa, and the residence time is controlled to be 2min. The micro-packed bed Gas-liquid phase separation was carried out at the outlet, and the obtained methanol solution was analyzed. The conversion rate of the reaction was 100%, and the yield of dibenzylamine was 90%.

Embodiment 3

[0036] Carry out experiment according to this method, configure the propanol solution of p-tert-butylbenzaldehyde, concentration is 20wt%, add phase-transfer catalyst benzyltriethylammonium chloride, add-on is 0.5% of substrate concentration to be hydrogenated, and Ammonia is mixed in the inlet T-type micro-mixer 1, and the molar ratio of ammonia / benzaldehyde is controlled to be 5:1, and then mixed with hydrogen in the inlet membrane dispersion micro-mixer 2, and the formed gas-liquid mixture passes through the ruthenium alumina The micro-packed bed reactor of the catalyst, the reaction temperature is controlled at 80°C, the pressure is 4.0MPa, and the residence time is controlled at 3min. The gas-liquid phase separation is carried out at the outlet of the micro-packed bed, and the obtained propanol solution is analyzed. The conversion rate of the reaction is 100%, the yield of p-tert-butylbenzylamine is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com