Device and method for complete methanation of synthesis gas

A complete methanation and synthesis gas technology, applied in the field of coal chemical industry, can solve the problems of catalyst wear and affecting the conversion rate of methanation reaction, etc., and achieve the effect of improving heat transfer capacity, reducing production cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

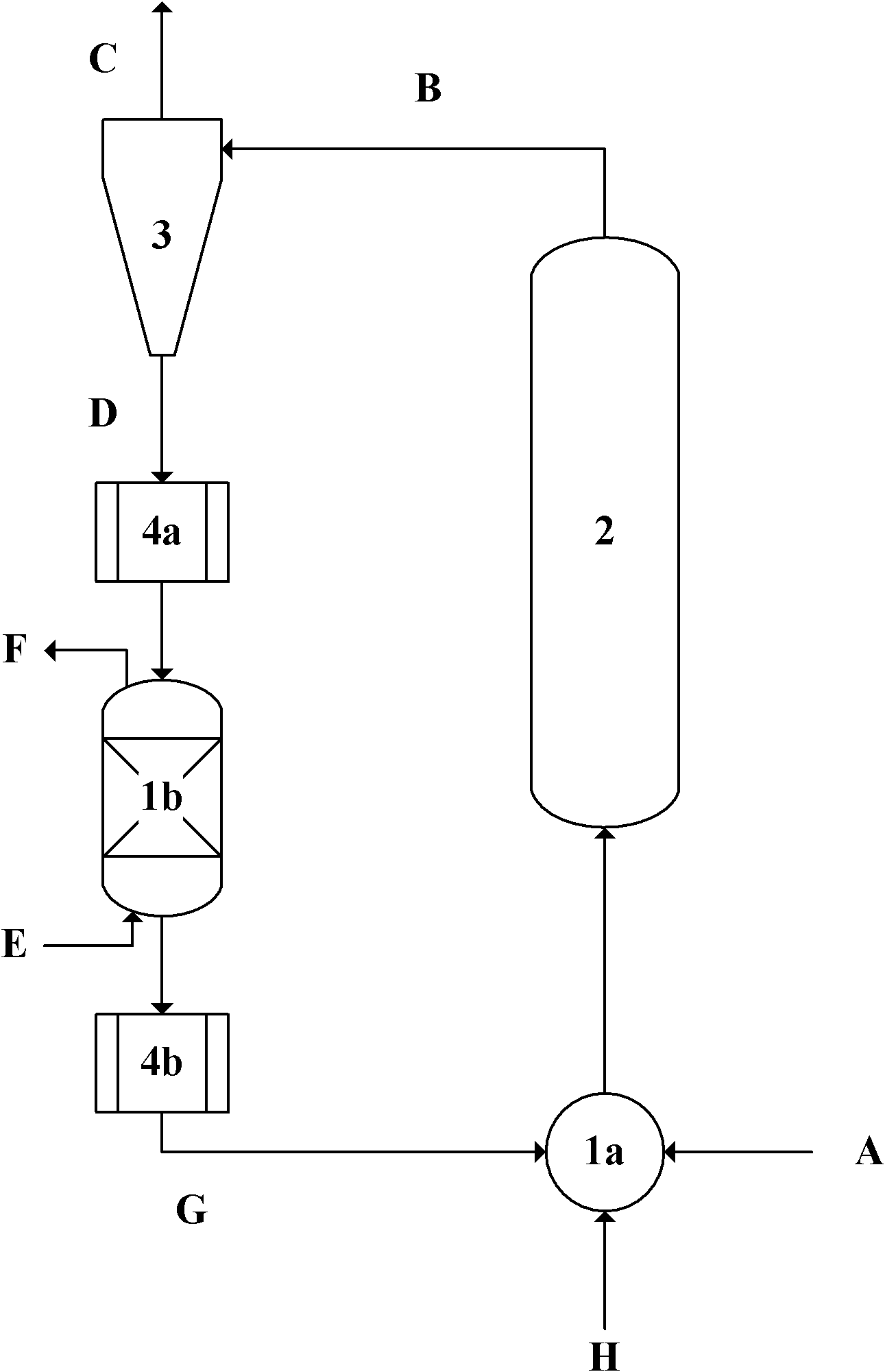

[0022] use as figure 1 The gas-solid-solid synthesis gas complete methanation device shown, the operation steps are as follows:

[0023] a. Using synthesis gas as raw material gas, the raw material gas and alumina microspheres are mixed in the mixer 1a, and after mixing, enter the gas-solid-solid reactor 2 equipped with a methanation catalyst, and in the gas-solid-solid Fully contact and react in Reactor 2; the molar ratio of hydrogen to carbon monoxide in the synthesis gas is 3.1, and the total volume flow rate is 5m 3 / h, the inlet temperature and outlet temperature of the gas-solid-solid reactor 2 are 370°C and 410°C respectively, and the operating pressure is 3.0MPa; the diameter of the catalyst particles is a cylinder with a diameter of φ5mm and a length of 3mm, and there are clover-shaped channel; the inner diameter of the gas-solid-solid reactor is 100mm, the height of the catalyst bed is 400mm; the particle size of alumina microspheres is 75 microns.

[0024] b, the ...

Embodiment 2

[0029] use as figure 1 The gas-solid-solid synthesis gas complete methanation device shown, the operation steps are as follows:

[0030] a. Using synthesis gas as the feed gas, mix the feed gas and quartz sand in the mixer 1a, after mixing, enter the gas-solid-solid reactor 2 equipped with a methanation catalyst, and in the gas-solid-solid reactor 2 for sufficient contact and reaction; the molar ratio of hydrogen to carbon monoxide in the synthesis gas is 3.5, and the total volume flow rate is 5m 3 / h, the inlet temperature and outlet temperature of the gas-solid-solid reactor 2 are 350°C and 390°C respectively, and the operating pressure is 3.0MPa; the diameter of the catalyst particles is a cylinder with a diameter of φ10mm and a length of 8mm, and there are clover-shaped channel; the inner diameter of the gas-solid-solid reactor is 100 mm, the height of the catalyst bed is 400 mm; the particle size of the quartz sand is 50 microns.

[0031] b, the gas-solid mixture coming...

Embodiment 3

[0036] use as figure 1 The gas-solid-solid synthesis gas complete methanation device shown, the operation steps are as follows:

[0037] a. Using synthesis gas as the feed gas, mix the feed gas and quartz sand in the mixer 1a, after mixing, enter the gas-solid-solid reactor 2 equipped with a methanation catalyst, and in the gas-solid-solid reactor 2 for sufficient contact and reaction; the molar ratio of hydrogen to carbon monoxide in the synthesis gas is 3.5, and the total volume flow rate is 5m 3 / h, the inlet temperature and outlet temperature of the gas-solid-solid reactor 2 are 350°C and 390°C respectively, and the operating pressure is 4.0MPa; the diameter of the catalyst particles is a cylinder with a diameter of φ10mm and a length of 6mm, and there are clover-shaped channel; the inner diameter of the gas-solid-solid reactor is 100 mm, the height of the catalyst bed is 400 mm; the particle size of the quartz sand is 75 microns.

[0038] b, the gas-solid mixture coming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com