Coupling reactor for synthesizing ethylene glycol by alkyl oxalate hydrogenation

The technology of alkyl oxalate and ethylene glycol is applied in the field of chemical technology, which can solve the problems of inability to guarantee the service life of the catalyst, uneven axial distribution of the fluid, and high catalyst loading coefficient, and achieves good industrial application prospects and uniform distribution of reaction gas. , Improve the effect of bed utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

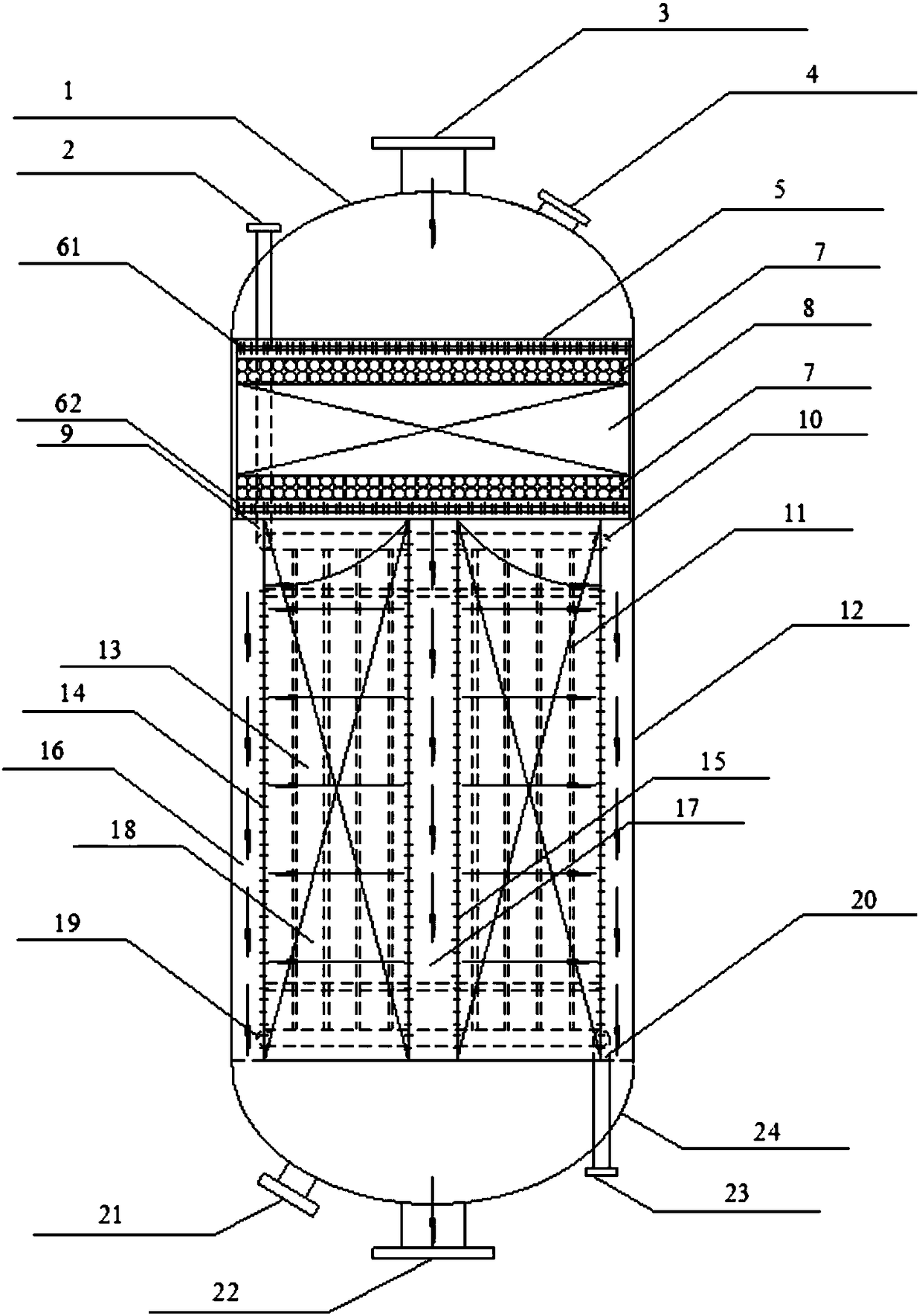

[0032] Such as figure 1 As shown, a coupling reactor for the hydrogenation of alkyl oxalate to ethylene glycol includes an upper head 1, a lower head 24 and a reactor shell arranged between the upper head 1 and the lower head 24 Body 12, upper head 1 is provided with reaction gas inlet 3, refrigerant outlet 2 and manhole 4, lower head 24 is provided with reaction gas outlet 22, refrigerant inlet 23 and catalyst discharge port 21, the inside of reactor shell 12 is composed of A first gas distributor 61 , an adiabatic reaction section 5 , a second gas distributor 62 , and an axial radial reaction section 13 are provided sequentially from top to bottom.

[0033] Wherein, the adiabatic reaction section 5 adopts a detachable overall frame structure, including refractory ceramic ball layers 7 arranged in parallel above and below, and an adiabatic section catalyst layer 8 arranged between the two refractory ceramic ball layers 7 .

[0034] The axial radial reaction section 13 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com