Axial-radial reactor for synthesizing ethylene glycol by alkyl oxalate hydrogenation

An alkyl oxalate and reactor technology, applied in the field of reactors, can solve the problems of uneven axial distribution of fluid, high catalyst loading coefficient, large production capacity, etc., to enhance heat transfer effect and reduce over-hydrogenation by-products , the effect of reducing the hot spot temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

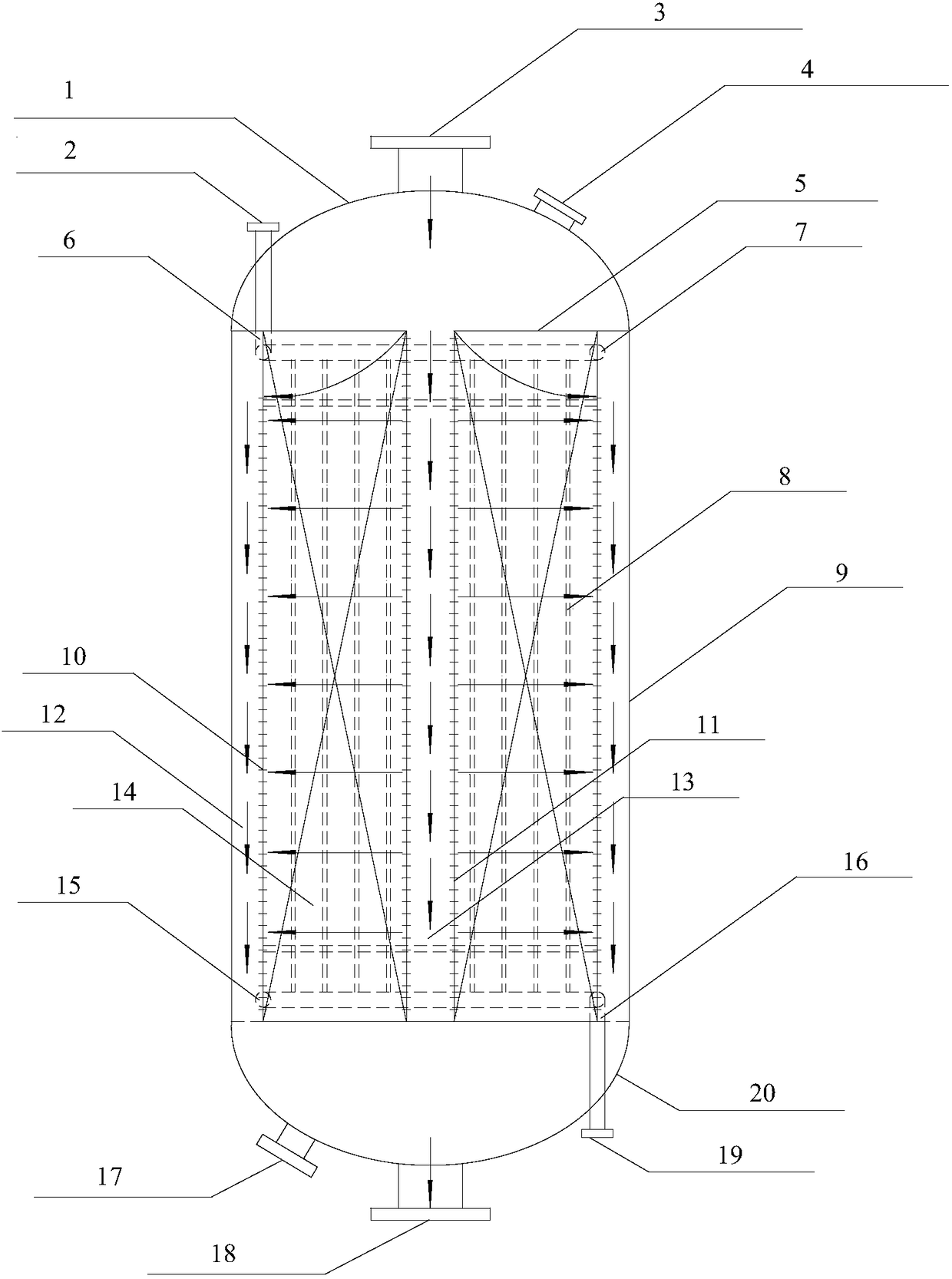

[0026] A radial reactor for the hydrogenation of alkyl oxalate to ethylene glycol (the alkyl oxalate in this embodiment can be selected from one of dimethyl oxalate, diethyl oxalate or dibutyl oxalate ),Such as figure 1 As shown, including the reactor body, the inside of the reactor body is provided with a shaft-diameter phase reaction zone 5, and the shaft-diameter reaction zone 5 is sequentially sleeved with an inner porous distribution cylinder 11 and an outer porous distribution cylinder 10. The cylinder 11 is used to form a distribution pipe 13, and one end is connected with a reaction gas inlet 3, and a first annular gap for placing a catalyst 14 is provided between the inner porous distribution cylinder 11 and the outer porous distribution cylinder 10, and the first annular gap is provided for A heat exchanger for exchanging heat with the catalyst, a second annulus for forming a header 12 is provided between the outer porous distribution cylinder 10 and the side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com