Method for preparing nitro-containing oxime ester photoinitiator by nitrification in micro-channel

A photoinitiator and microchannel technology, which is applied in chemical instruments and methods, formation/introduction of nitro/nitroso groups, oxime preparation, etc., can solve problems such as inability to use sulfuric acid and nitric acid, difficulty in obtaining target products, and safety issues, etc. problems, to achieve the effect of improving reaction efficiency and safety, enhancing mass transfer and heat transfer capabilities between phases, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

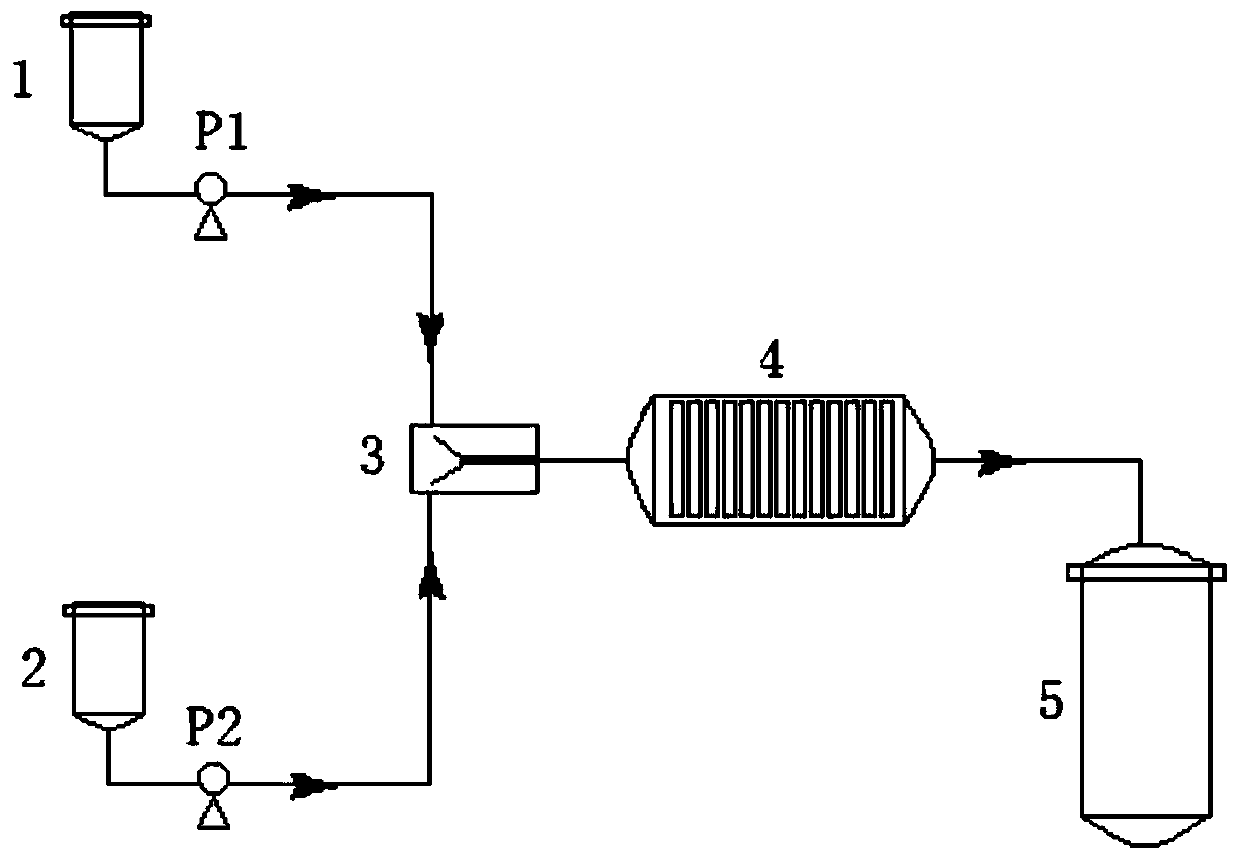

Method used

Image

Examples

Embodiment 1

[0041]

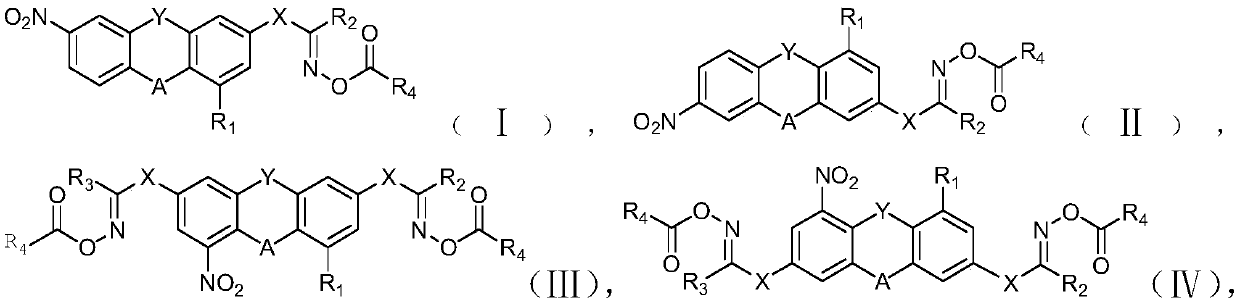

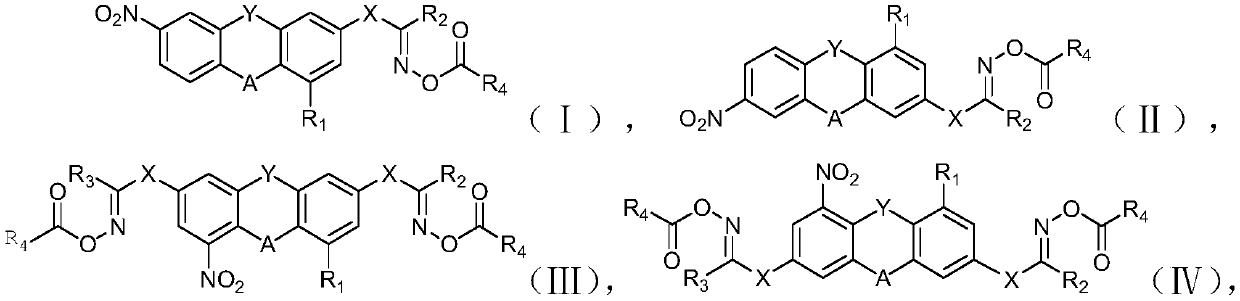

[0042] The oxime ester initiator intermediate uses N-ethyl carbazole as a raw material, and is prepared through well-known acylation reactions, oximation reactions and esterification reactions.

[0043] Dissolving the oxime ester initiator intermediate in the inert solvent dichloromethane and acetic anhydride to form a solution with a mass fraction of 5% is used as a continuous phase, with nitric acid (mass concentration 60%) as a dispersed phase, the mass fraction of nitric acid and acetic anhydride The ratio is 0.1, the temperature of the nitrification reaction is controlled to be 0°C, and the pressure is 0.3 MPa. The dispersed phase is dispersed into the continuous phase in the membrane dispersed microchannel reactor. The molar ratio of the active ingredient in the nitric acid to the oxime ester initiator intermediate is 2.2, control the residence time of the mixed material (i.e. the nitration reaction time, the same below) to be 5min, after the reaction, the mat...

Embodiment 2

[0045] Using the oxime ester initiator intermediate in Example 1 as a raw material, the experiment was carried out according to this method, and the oxime ester initiator intermediate was dissolved in dimethylformamide and acetic anhydride to form a solution with a mass fraction of 20%. As the continuous phase, nitric acid (mass concentration 60%) is used as the dispersed phase, the mass ratio of nitric acid and acetic anhydride is 0.5, the controlled nitration reaction temperature is 20°C, and the pressure is 0.5MPa. Dispersed in the continuous phase, the molar ratio of active ingredient in nitric acid to oxime ester initiator intermediate is 2.8, and the residence time of the mixed material (i.e. nitration reaction time) is controlled to be 5min. After the reaction, the material enters the phase separation tank for phase separation. The obtained solution was analyzed, and the conversion rate of the oxime ester initiator intermediate was 98.3%, and the selectivity of the produ...

Embodiment 3

[0047]

[0048] Oxime ester initiator intermediate Ⅱ

[0049] The oxime ester initiator intermediate II is prepared from diphenyl sulfide through well-known acylation reaction, oximation reaction and esterification reaction.

[0050] Carry out experiment according to this method, dissolve initiator intermediate in ethylene dichloride and acetic anhydride and be made into the solution that mass fraction is 10% as continuous phase, take nitric acid (mass concentration 60%) as dispersed phase, nitric acid and acetic anhydride The mass ratio is 0.2, the control reaction temperature is 10°C, the pressure is 0.5MPa, the dispersed phase is dispersed into the continuous phase in the membrane dispersed microchannel reactor, and the molar ratio of nitric acid to oxime ester initiator intermediate II is 2.3 , the residence time of the mixed material is controlled to be 8min, and finally the material enters the phase separation tank for phase separation, and the obtained solution is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com