Downward chilling external heat removal pulverized coal pressurized gasification device

A technology of pressurized gasification and dry coal powder, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. Outage and other problems, to achieve the effect of improving heat removal capacity, improving safe operation stability, and simplifying the gasification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

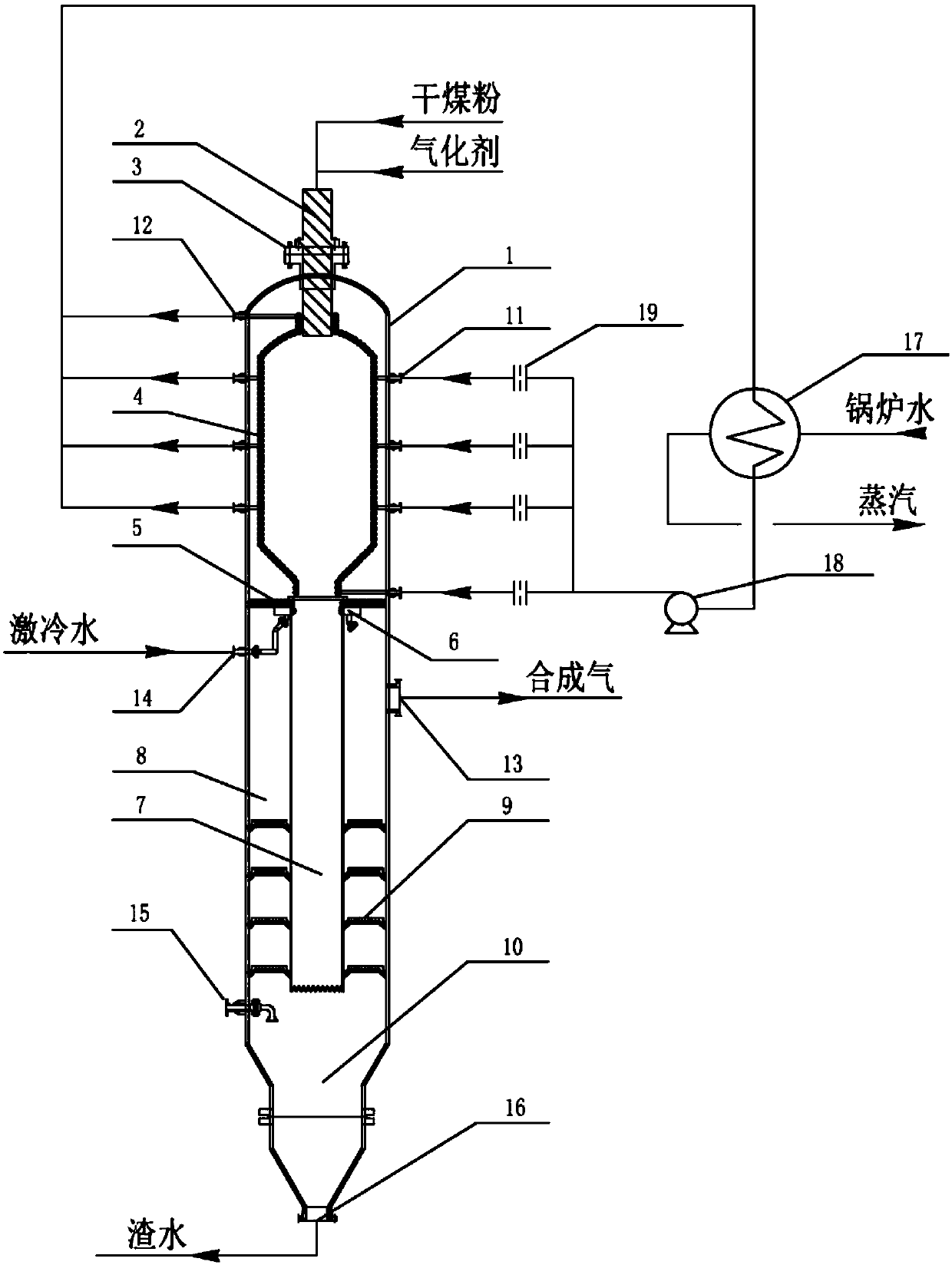

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

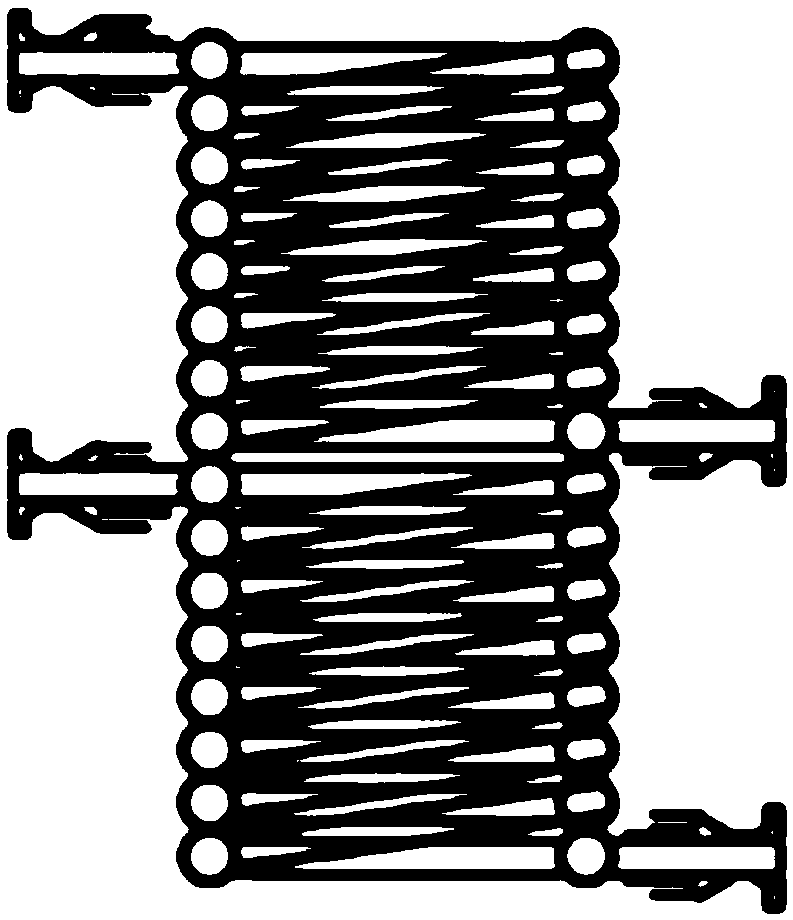

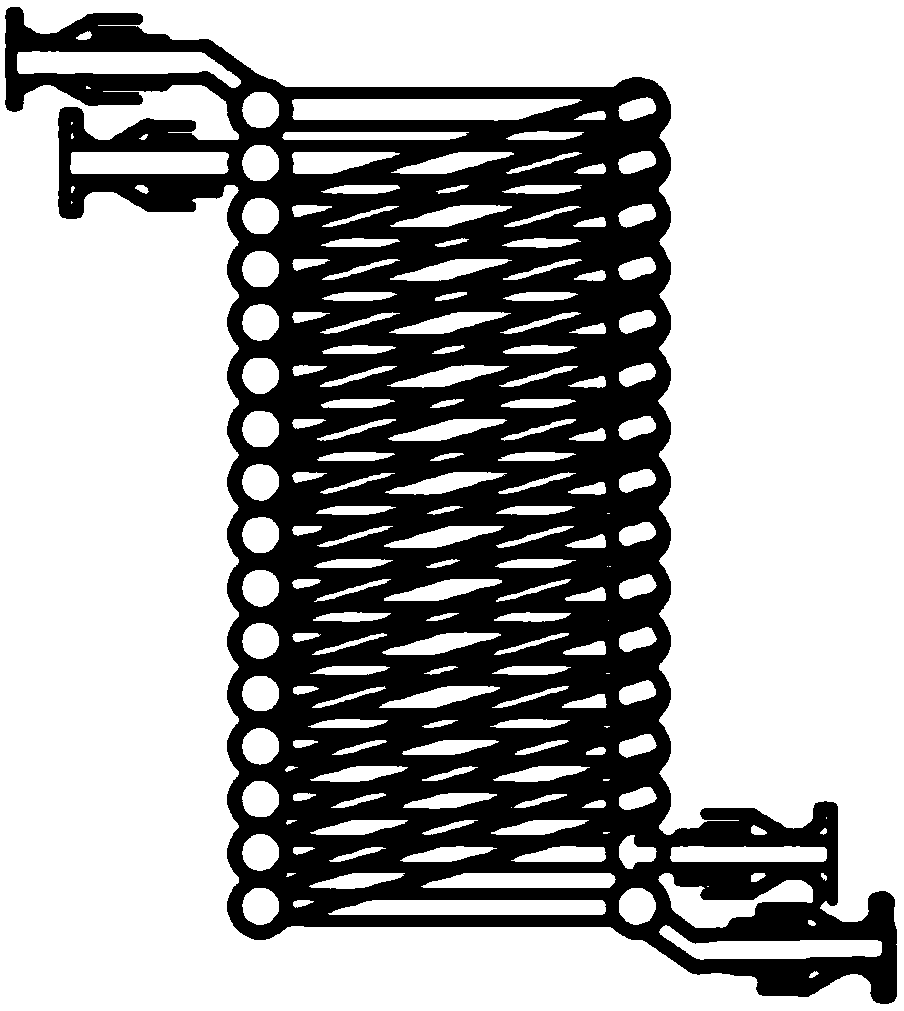

[0023] refer to figure 1 , the pressurized gasification device for dry pulverized coal that transfers heat outside the downstream quenching furnace according to the present invention includes a heat transfer system outside the furnace, a gasifier shell 1 and a partition plate arranged in the gasifier shell 1 5. Among them, the gasifier shell 1 is divided into a water-cooled wall installation cavity at the top and a quenching chamber 8 at the bottom by a partition plate 5, wherein a water-cooled wall 4 is arranged in the water-cooled wall installation cavity, and the interior of the water-cooled wall 4 A gasification reaction chamber is formed, the inlet of the heat transfer system outside the furnace is connected with the outlet of the water-cooled wall 4, the outlet of the heat transfer system outside the furnace is connected with the inlet of the water-cooled wall 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com