Liquid-cooling heat radiating device

A liquid-cooled heat dissipation and heat dissipation technology, which is applied in cooling/ventilation/heating transformation, indirect heat exchangers, lighting and heating equipment, etc. It can solve the problem of limited contact area between metal plates and pipes, which limits the overall heat dissipation performance of liquid-cooled heat sinks , limiting the ability to transfer heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

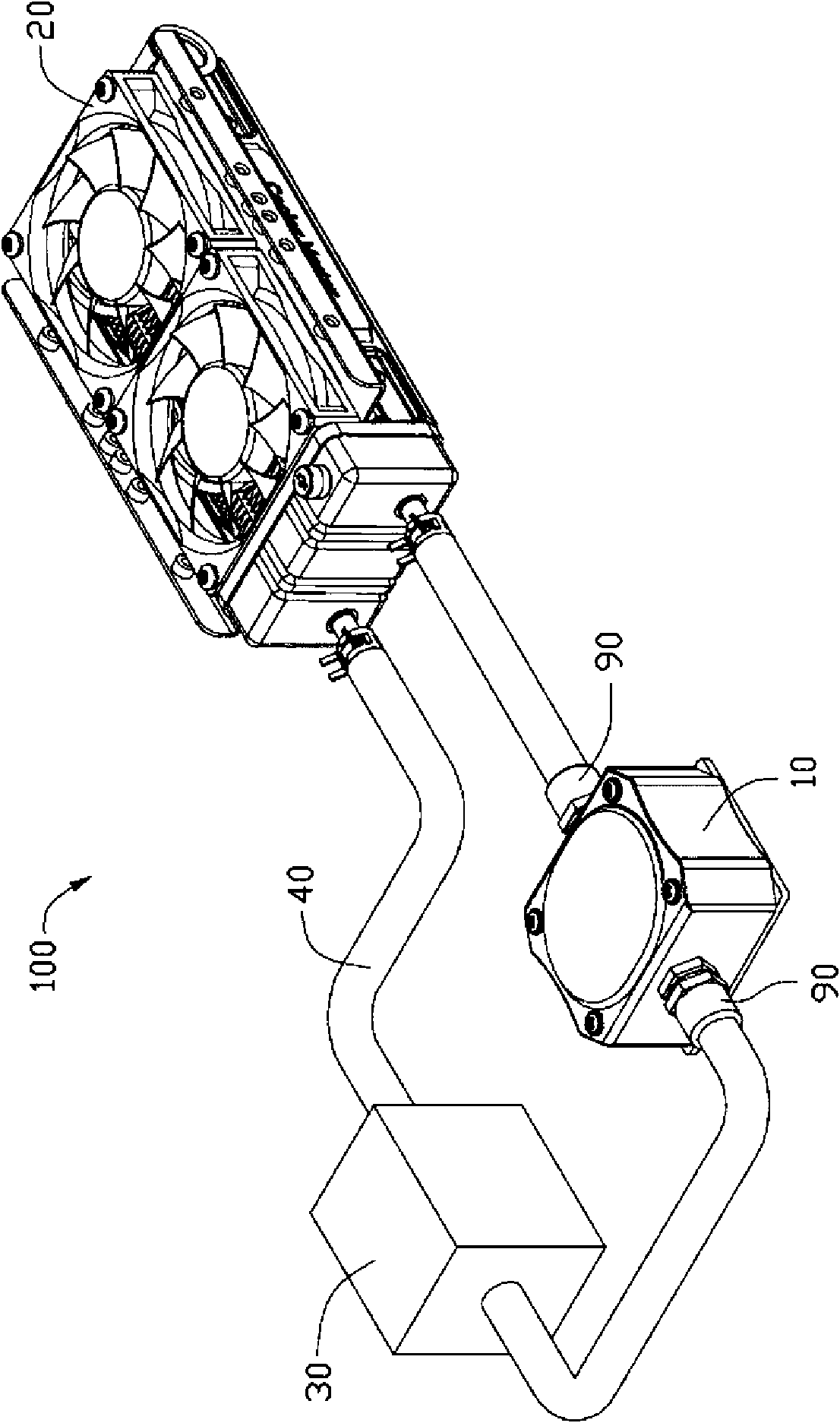

[0012] see figure 1 , the liquid cooling device 100 includes a heat absorber 10 , a heat sink 20 and a driver. The driver can be a pump 30 . The heat absorbing body 10 , the cooling body 20 and the pump 30 are sequentially connected to form a circuit through the pipeline 40 . This circuit is filled with cooling liquid.

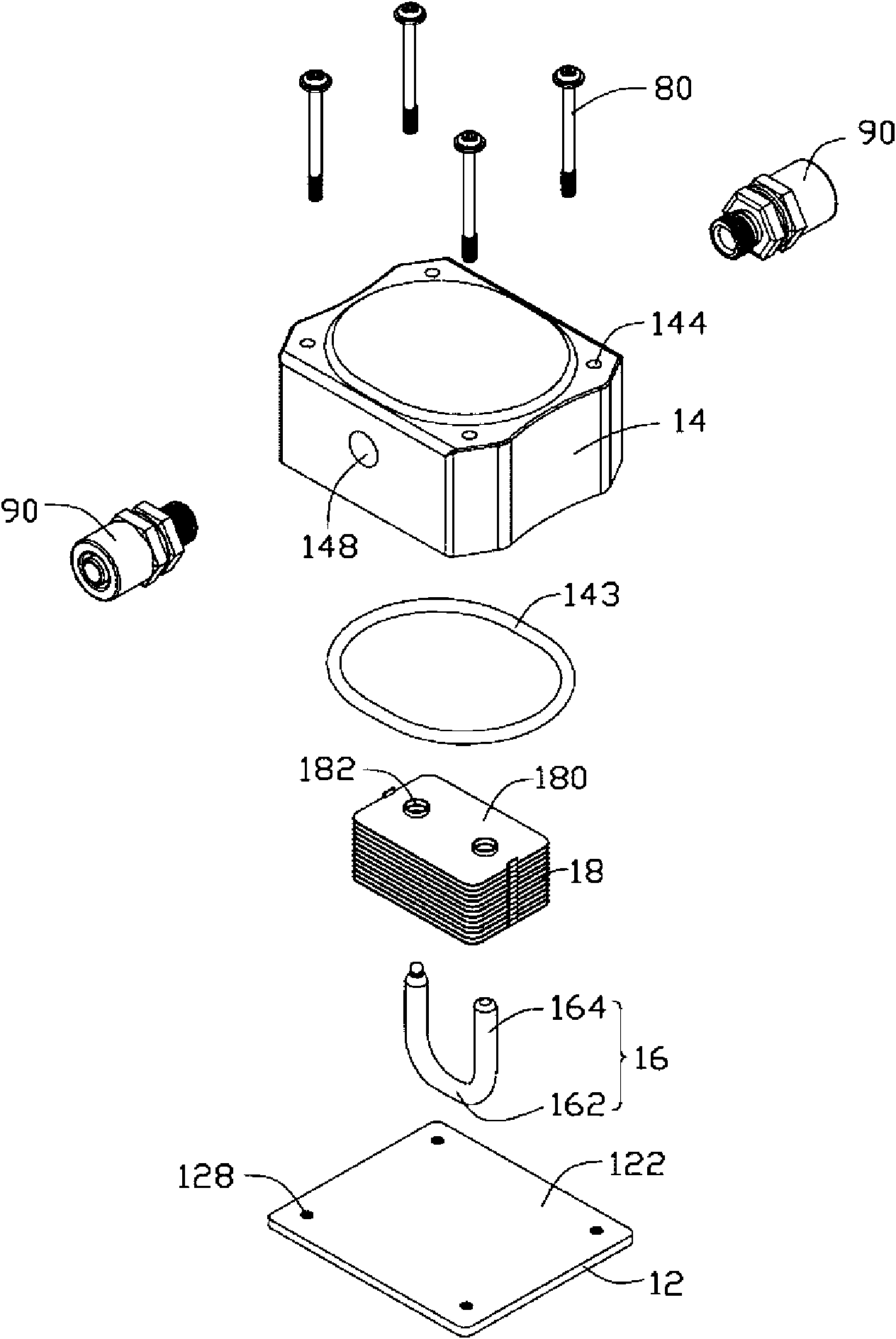

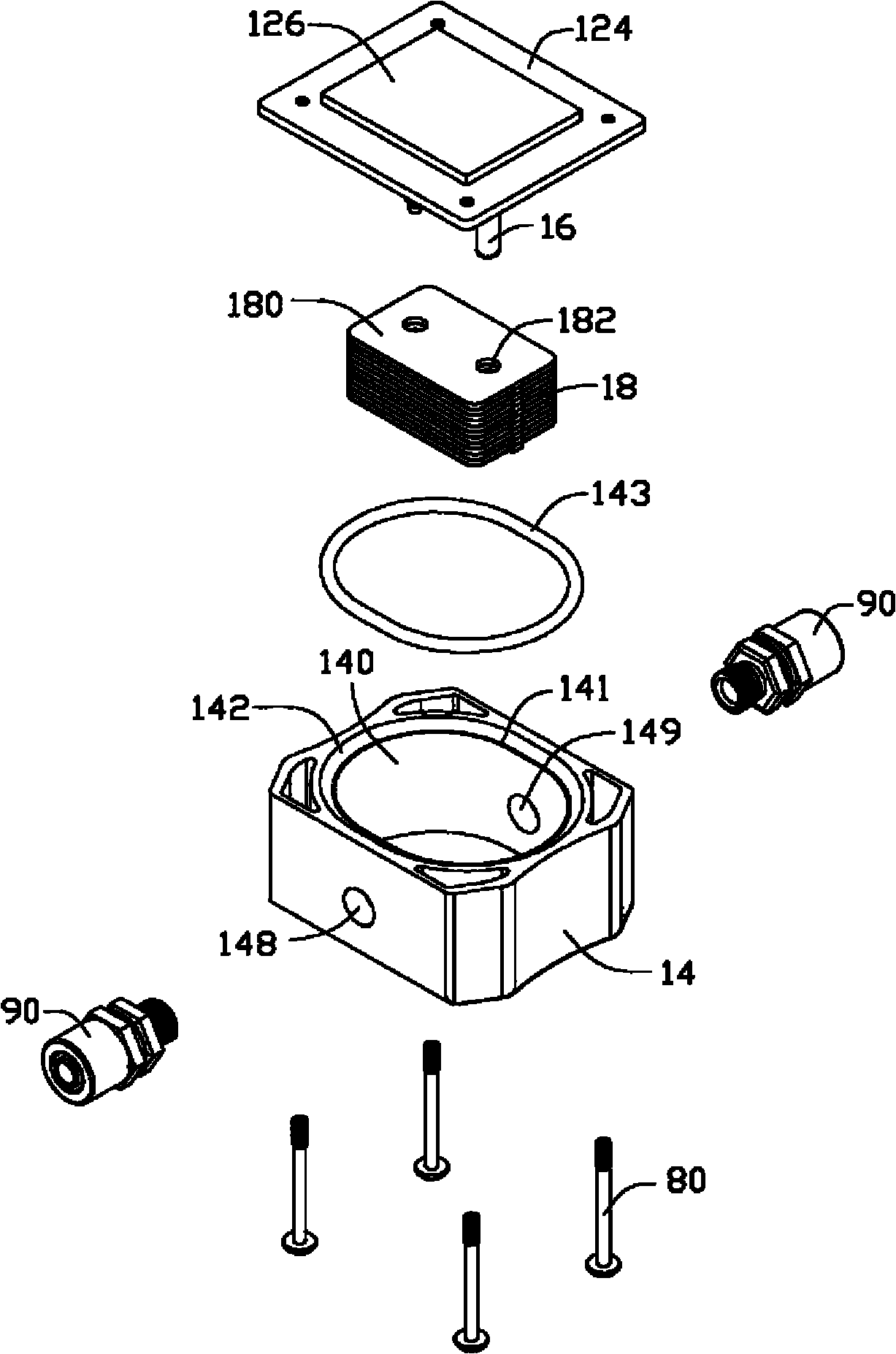

[0013] Please also see figure 2 and image 3 , the heat absorbing body 10 includes a heat absorbing plate 12, a radiator 18 positioned above the heat absorbing plate 12, a heat pipe 16 connecting the heat absorbing plate 12 and the radiator 18, and a cover disposed on the heat absorbing plate 12 and A cover 14 sealingly connected with the heat absorbing plate 12 . The heat absorbing plate 12 is made of a metal material with good thermal conductivity, such as copper. The heat absorbing plate 12 is substantially flat and has a flat upper surface 122 . The lower surface 124 of the heat absorbing plate 12 protrudes downward to form a flat square contact su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com