Spiral pipe jacket type axial reactor

A jacketed, reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problem of high temperature of the serpentine heat exchanger, achieve a large filling capacity, and eliminate the carbonylation reactor and carbonylation system. The effect of explosion and heat transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

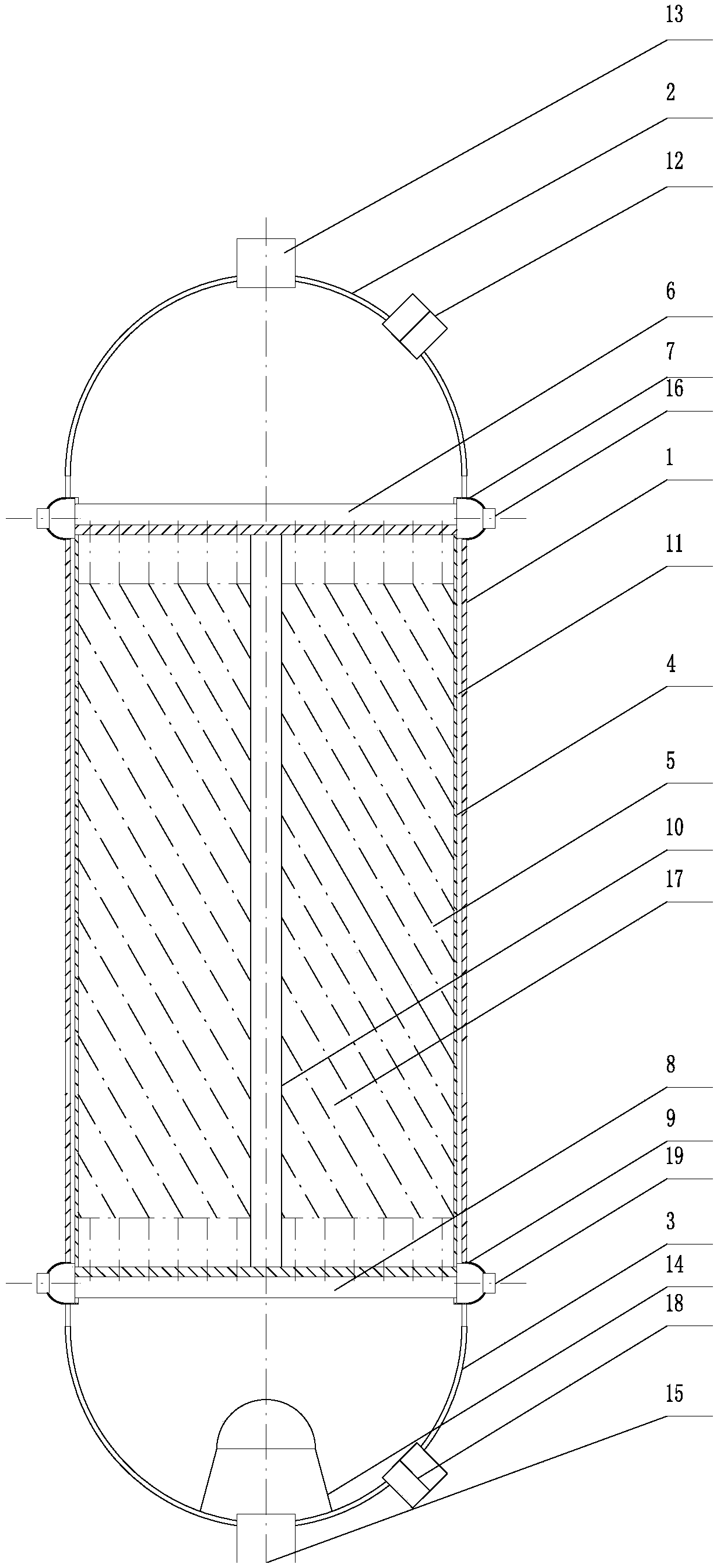

[0023] like figure 1 As shown, this embodiment includes a cylinder body 1, an upper head 2, a lower head 3, a water jacket inner plate 4, a serpentine heat exchange tube 5, an upper flat tube sheet header 6, a water collection tank 7, and a lower flat tube sheet Header 8, water distribution tank 9, central fixed cylinder 10; the upper head 2 and the lower head 3 are respectively fixed on the top and bottom of the cylinder 1, and the serpentine heat exchange tube 5 is along the axial direction of the cylinder 1 distribution, the upper flat tube sheet header 6 communicates with the water outlet end of the serpentine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com