Low-resistance and energy-saving flue gas denitration catalyst module

A denitration catalyst and energy-saving technology, which is applied in gas treatment, chemical instruments and methods, dispersed particle separation, etc., can solve the obstacles to the promotion and application of clover-type catalysts, affect the normal operation of denitrification and desulfurization systems, and affect the efficiency of denitration and desulfurization, etc. problem, to achieve the effect of increasing the size of the cross-sectional area of the flue gas flow, ensuring the strength, and reducing the resistance of the module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

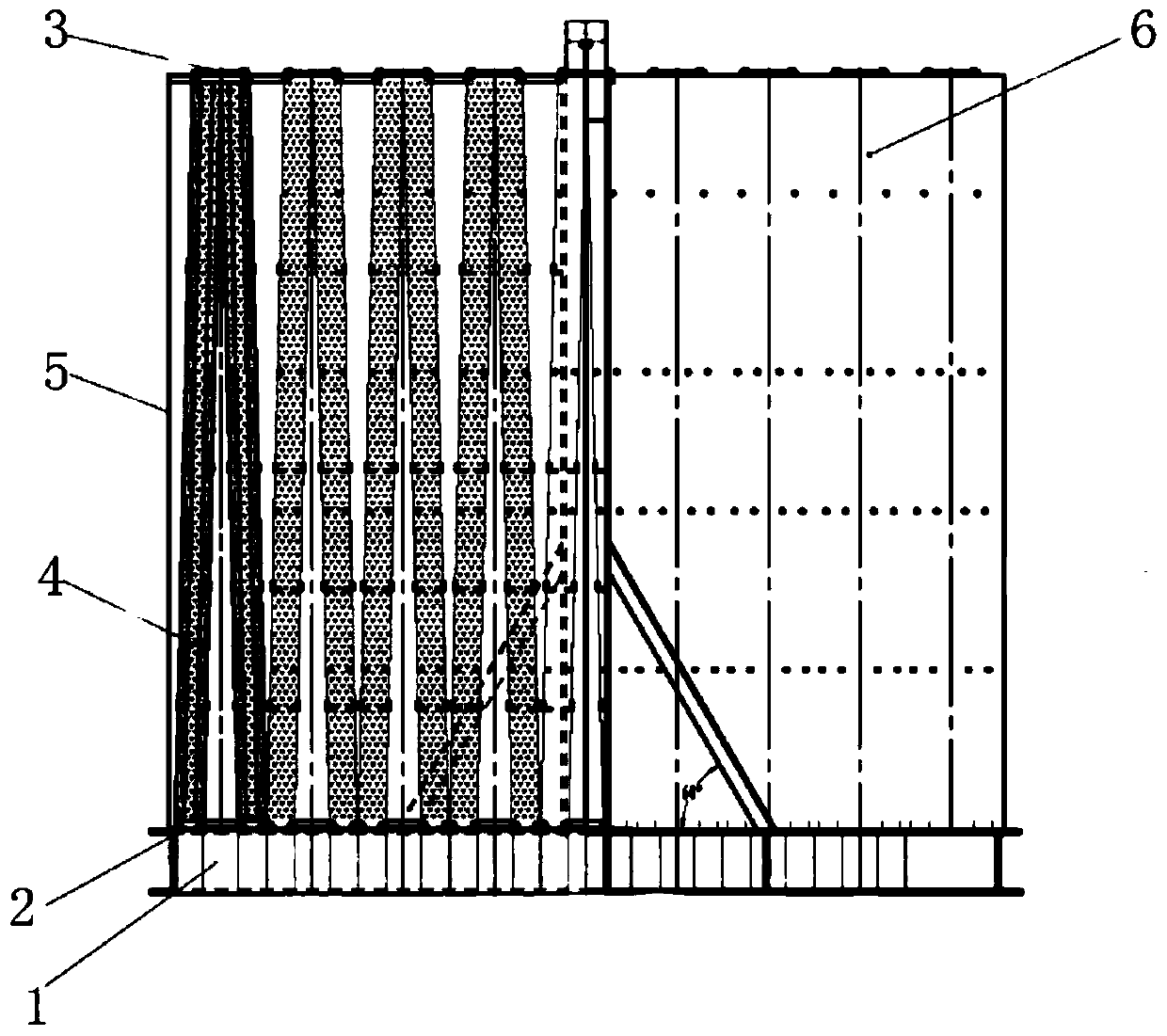

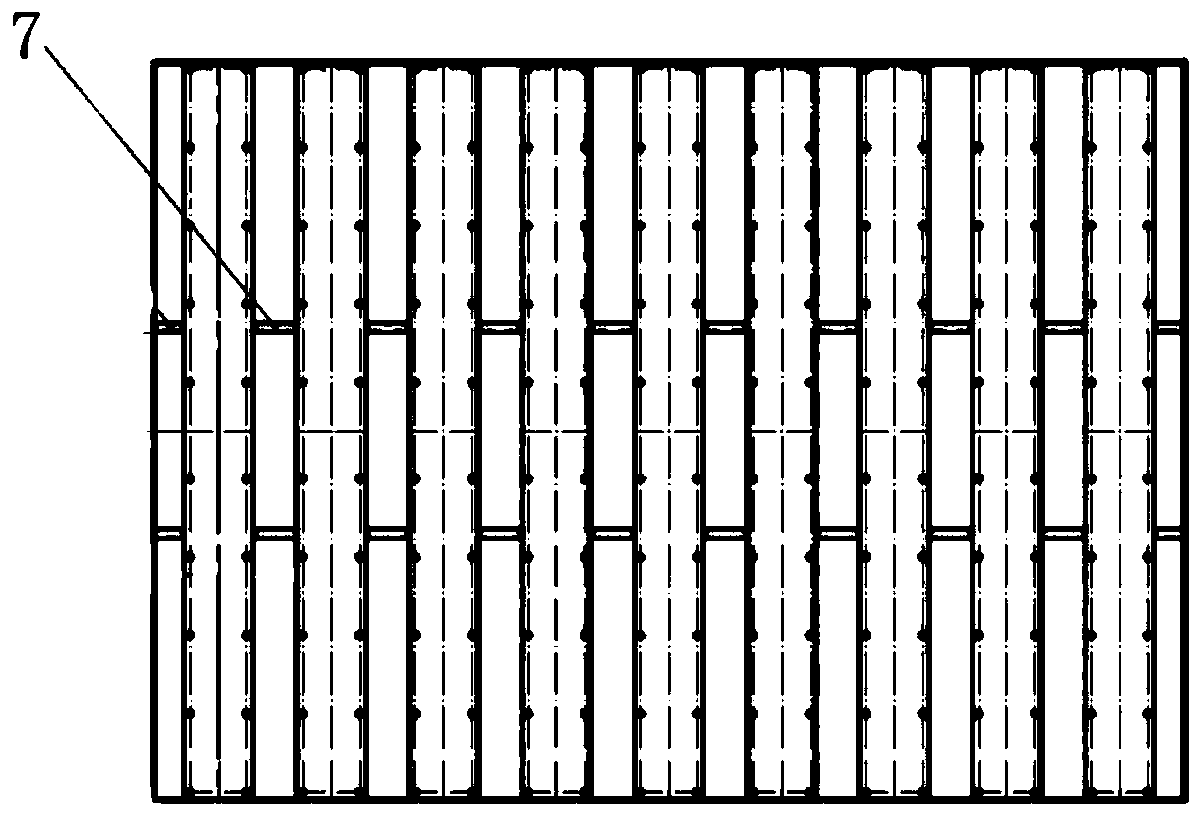

[0018] A low-resistance and energy-saving flue gas denitrification catalyst module provided in this embodiment has a structure such as Figure 1-2 As shown, including a module base 1, a module frame is provided on the module base 1, and the module frame includes a bottom sealing plate 2, a top cover plate 3, a catalyst skeleton 4, an end wall plate 5 and a side wall plate 6, and each part of the module frame are connected and fixed by a fixing device. The catalyst framework 4 is a wire mesh framework or a porous plate framework, and several reinforcing partitions 7 are arranged on the catalyst framework 4 . The bottom sealing plate 2 is located above the module base 1, the end wall panels 5 and the side wall panels 6 are vertically arranged around the bottom sealing panel 2 respectively, and the top cover plate 3 covers the end wall panels 5 and the side wall panels 6, the catalyst skeleton 4 is evenly arranged in the module frame in a W shape, and the catalyst is placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com