Preparation method of conducting shell-like layered graphene composite material

A composite material and layered graphite technology, applied in the field of preparation of conductive shell-like layered graphene composite materials, can solve problems such as decreased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

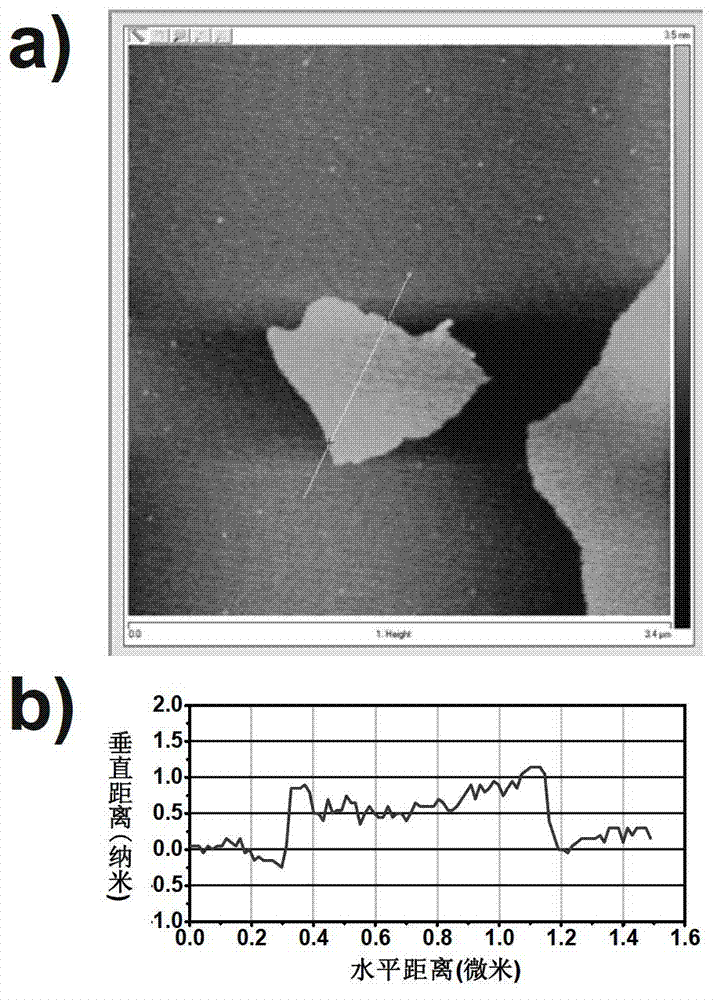

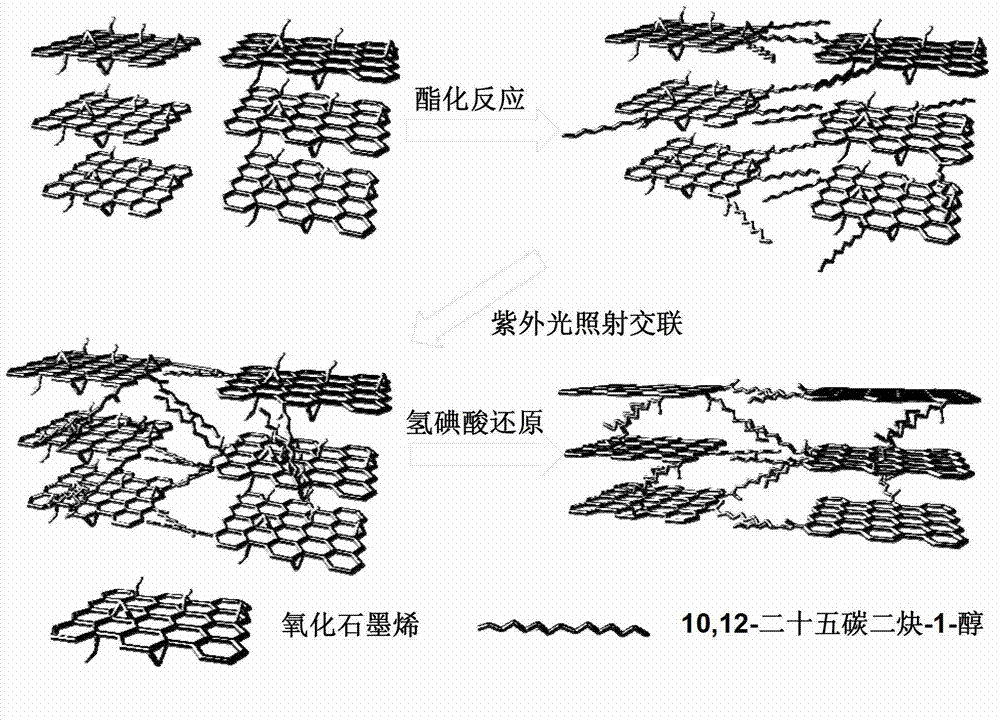

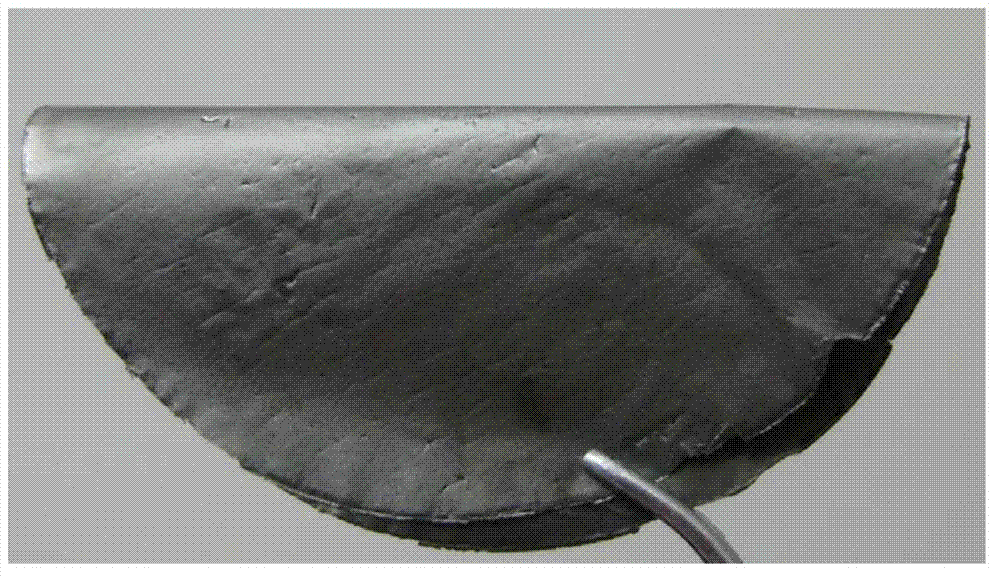

[0029] Weigh 10 mg of graphene oxide, mechanically stir and disperse in 100 ml of deionized water, and then ultrasonically disperse for 1 h to form a light yellow transparent solution. The light yellow transparent solution was further centrifuged to remove undispersed agglomerated particles and multilayer graphene oxide sheets. The centrifugation speed is 5000r / min, the centrifugation time is 10min, and the supernatant is taken. At this point, a single-layer graphene oxide sheet can be obtained, and the atomic force photograph shows that the thickness of the graphene oxide sheet is about 1 nm, such as figure 1 as shown, figure 1 a is an atomic force scanning photo of a single-layer graphene oxide sheet, figure 1 b is corresponding to figure 1 a The thickness of the graphene oxide sheet. The graphene oxide film was obtained by vacuum filtration. Under dark conditions, weigh 7 mg of 10,12-pentacosadiyn-1-ol (PCDO), dissolve it in 17.2 g of tetrahydrofuran, and make a concen...

Embodiment 2

[0031] Weigh 20 mg of graphene oxide, mechanically stir and disperse in 100 ml of deionized water, and then ultrasonically disperse for 1 h to form a light yellow transparent solution. The light yellow transparent solution was further centrifuged to remove undispersed agglomerated particles and multilayer graphene oxide sheets. The centrifugation speed is 6000r / min, the centrifugation time is 30min, and the supernatant is taken. The graphene oxide film was obtained by vacuum filtration. Under dark conditions, weigh 7 mg of 10,12-pentacosadiyn-1-ol (PCDO), dissolve it in 17.2 g of tetrahydrofuran, and make a concentration of about 10 -2 mol / L PCDO solution, the graphene oxide film was immersed in the PCDO solution, and reacted in the dark for 1 h. Take out the graphene oxide-PCDO composite material after the esterification reaction, wash it with tetrahydrofuran solvent for 2~3 times, remove the unreacted PCDO, and after the solvent is completely evaporated, irradiate it with ...

Embodiment 3

[0033] Weigh 30 mg of graphene oxide, mechanically stir and disperse in 100 ml of deionized water, and then ultrasonically disperse for 2 hours to form a light yellow transparent solution. The light yellow transparent solution was further centrifuged to remove undispersed agglomerated particles and multilayer graphene oxide sheets. The centrifugation speed is 7000r / min, the centrifugation time is 40min, and the supernatant is taken. The graphene oxide film was obtained by vacuum filtration. Under light-shielded conditions, weigh 14 mg of 10,12-pentacosadiyn-1-ol (PCDO), dissolve it in 17.2 g of tetrahydrofuran, and make a concentration of about 2×10 -2 mol / L PCDO solution, the graphene oxide film was immersed in the PCDO solution, and reacted in the dark for 2 hours. Take out the graphene oxide-PCDO composite material after the esterification reaction, wash it with tetrahydrofuran solvent for 2~3 times, remove the unreacted PCDO, and after the solvent is completely evaporate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com