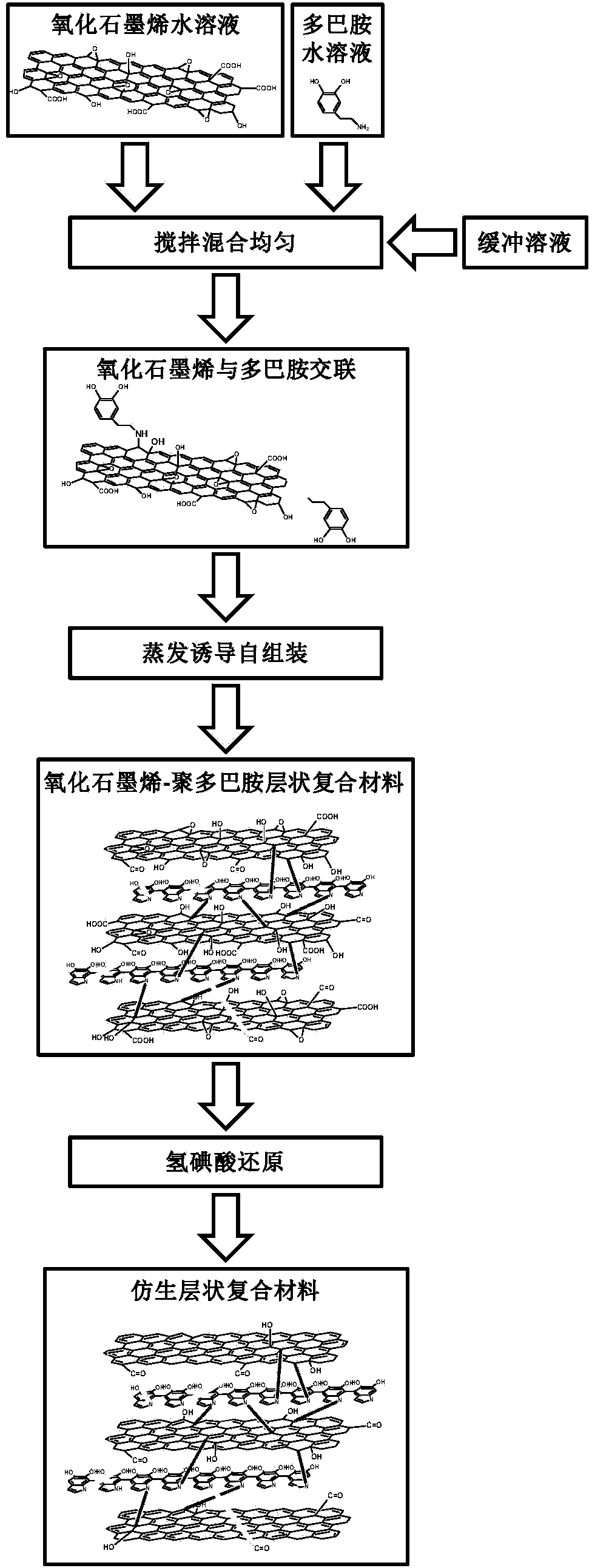

Method for preparing tough integrated biomimetic layered graphene composite material

A composite material and graphene technology, which is applied in the field of nano-biomimetic composite material preparation, can solve the problems such as the construction of layered composite materials without reported dopamine/graphene oxide, and achieve good electrical conductivity, complete composite material structure, and good electrical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

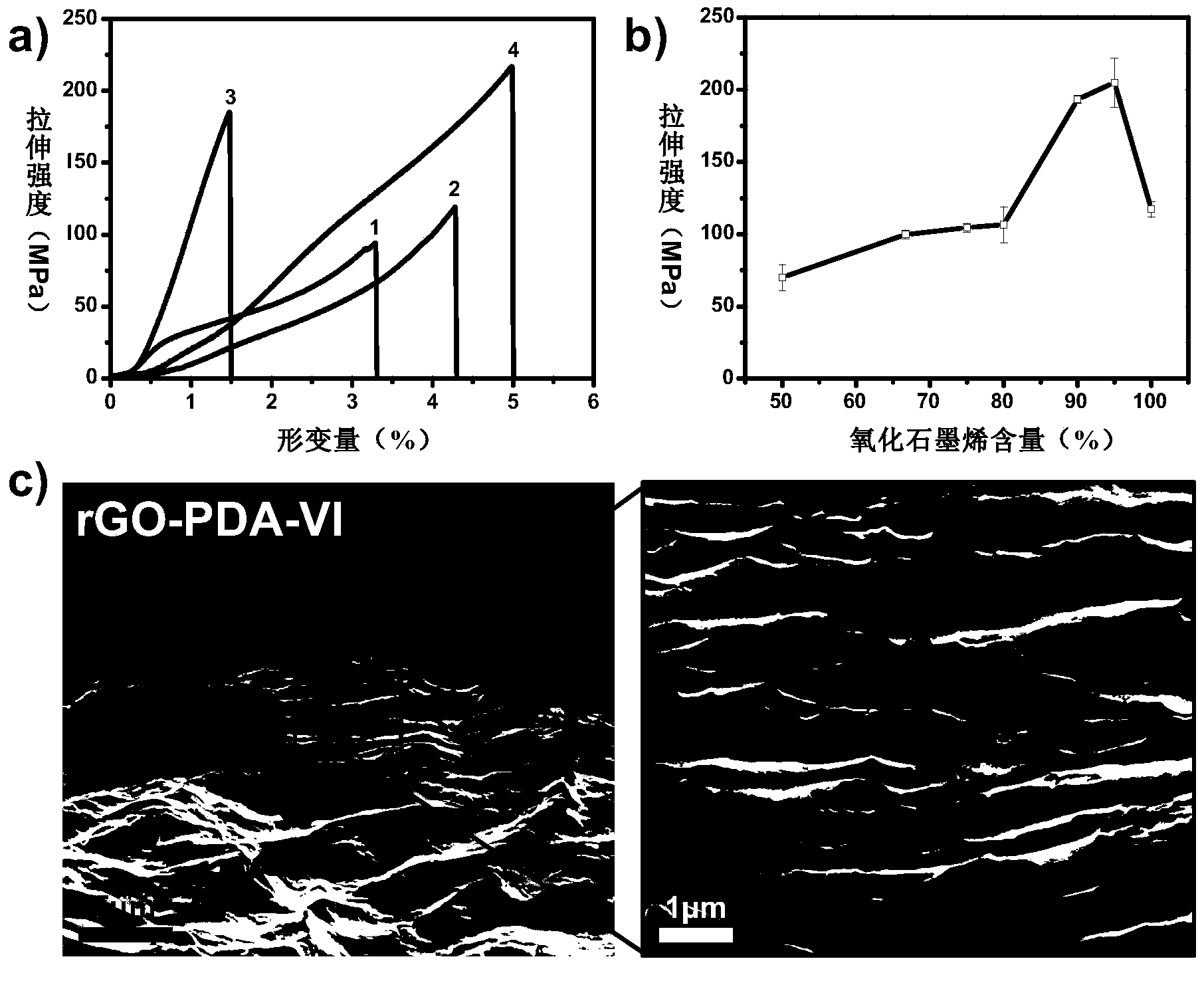

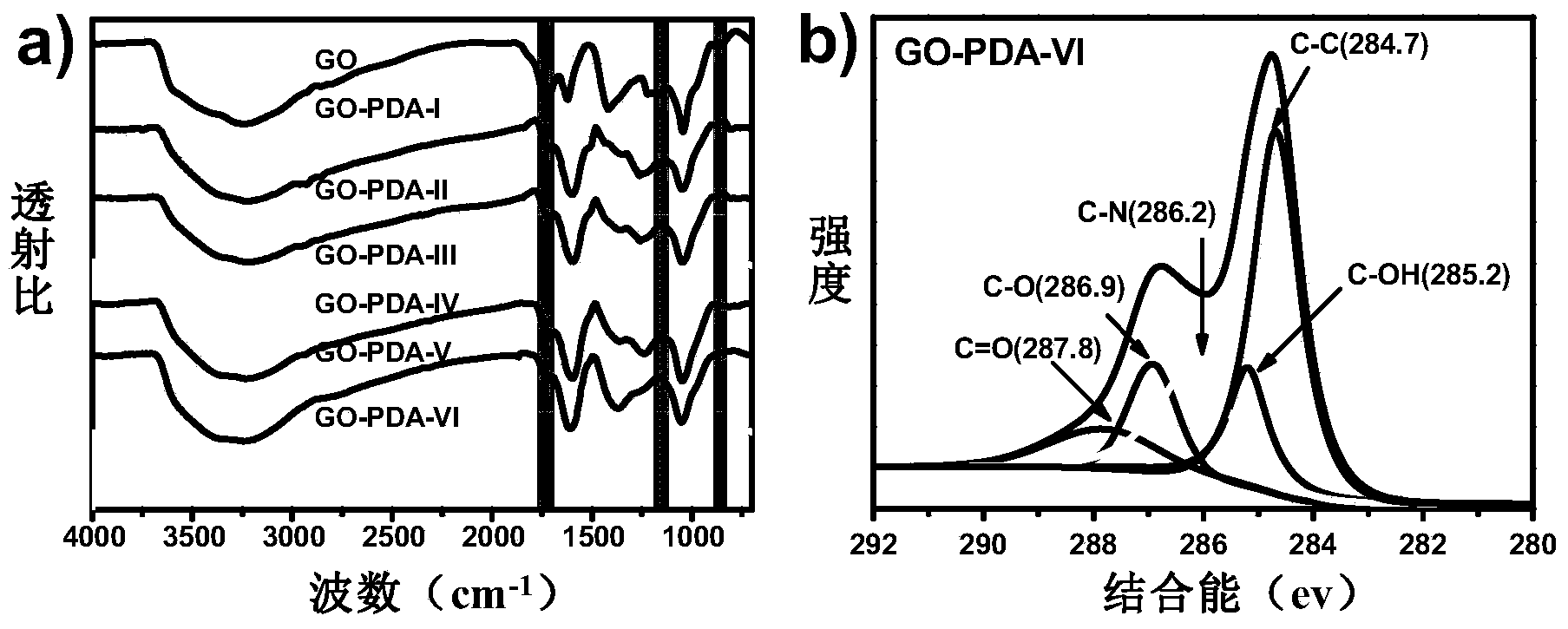

[0030] Weigh 30 mg of graphene oxide, mechanically stir and disperse in 20 ml of deionized water, and then ultrasonically disperse for 1 h to form a brown transparent solution. Add 15ml of Tris (PH=8.5) buffer solution and 30mg of dopamine powder into the graphene oxide solution, and continue to stir. During this process, the solution turns from brown to black. Continue to stir for 12 hours, and dopamine and graphene oxide are covalently cross-linked , to mix the solution evenly. The graphene oxide-dopamine film composite material (GO-PDA-I, content of graphene oxide 50wt%) was obtained by evaporating to dryness in an oven (temperature 45° C.). After the reaction was completed, the graphene oxide-dopamine composite material was immersed in the hydroiodic acid solution and kept at 25 °C for 6 h. Then, wash with ethanol to remove excess hydroiodic acid, and dry to obtain biomimetic layered composite materials, such as figure 1 shown. Mechanical properties tests show that the ...

Embodiment 2

[0032] Weigh 40 mg of graphene oxide, mechanically stir and disperse in 20 ml of deionized water, and then ultrasonically disperse for 1 h to form a brown transparent solution. Add 15ml of Tris (PH=8.5) buffer solution and 20mg of dopamine powder into the graphene oxide solution, and continue stirring. During this process, the solution turns from brown to black. Stirring was continued for 12 hours, and dopamine and graphene oxide were covalently cross-linked to obtain a uniformly mixed solution. The graphene oxide-dopamine film composite material (GO-PDA-II, content of graphene oxide 67.7wt%) was obtained by evaporating to dryness in an oven (temperature 50° C.). After the reaction was completed, the graphene oxide-dopamine composite material was immersed in the hydroiodic acid solution and kept at 25 °C for 6 h. Then, rinse with carbon tetrachloride to remove excess hydroiodic acid and allow to dry. Its mechanical properties test shows that the tensile strength of the graph...

Embodiment 3

[0034] Weigh 45 mg of graphene oxide, mechanically stir and disperse in 20 ml of deionized water, and then ultrasonically disperse for 1 h to form a brown transparent solution. Add 15ml of Tris (PH=8.5) buffer solution and 15mg of dopamine powder into the graphene oxide solution, and continue stirring. During this process, the solution turns from brown to black. Stirring was continued for 12 hours, and dopamine and graphene oxide were covalently cross-linked to obtain a uniformly mixed solution. The graphene oxide-dopamine film composite material (GO-PDA-III, content of graphene oxide 75wt%) was obtained by steaming in an oven (at a temperature of 55° C.). After the reaction was completed, the graphene oxide-dopamine composite material was immersed in the hydroiodic acid solution and kept at 25 °C for 6 h. Then, wash with ethanol to remove excess hydroiodic acid and allow to dry. Mechanical properties tests show that the graphene oxide composite material has a tensile streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com