Carbon fibre bar containing super fine and preparation thereof

A technology of ultra-fine powder and carbon fiber rods, which is applied in the field of composite materials, can solve the problems of difficult matching of composite material molding process, difficulty in uniform dispersion of nano-scale and micron-scale particles, etc., and achieve uniform appearance, tensile strength and bending strength performance Excellent, good surface regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

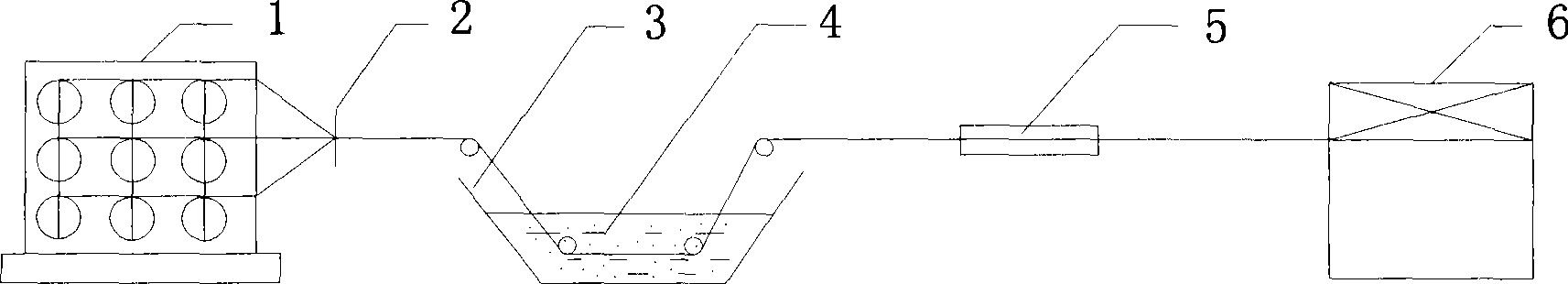

Method used

Image

Examples

Embodiment 1

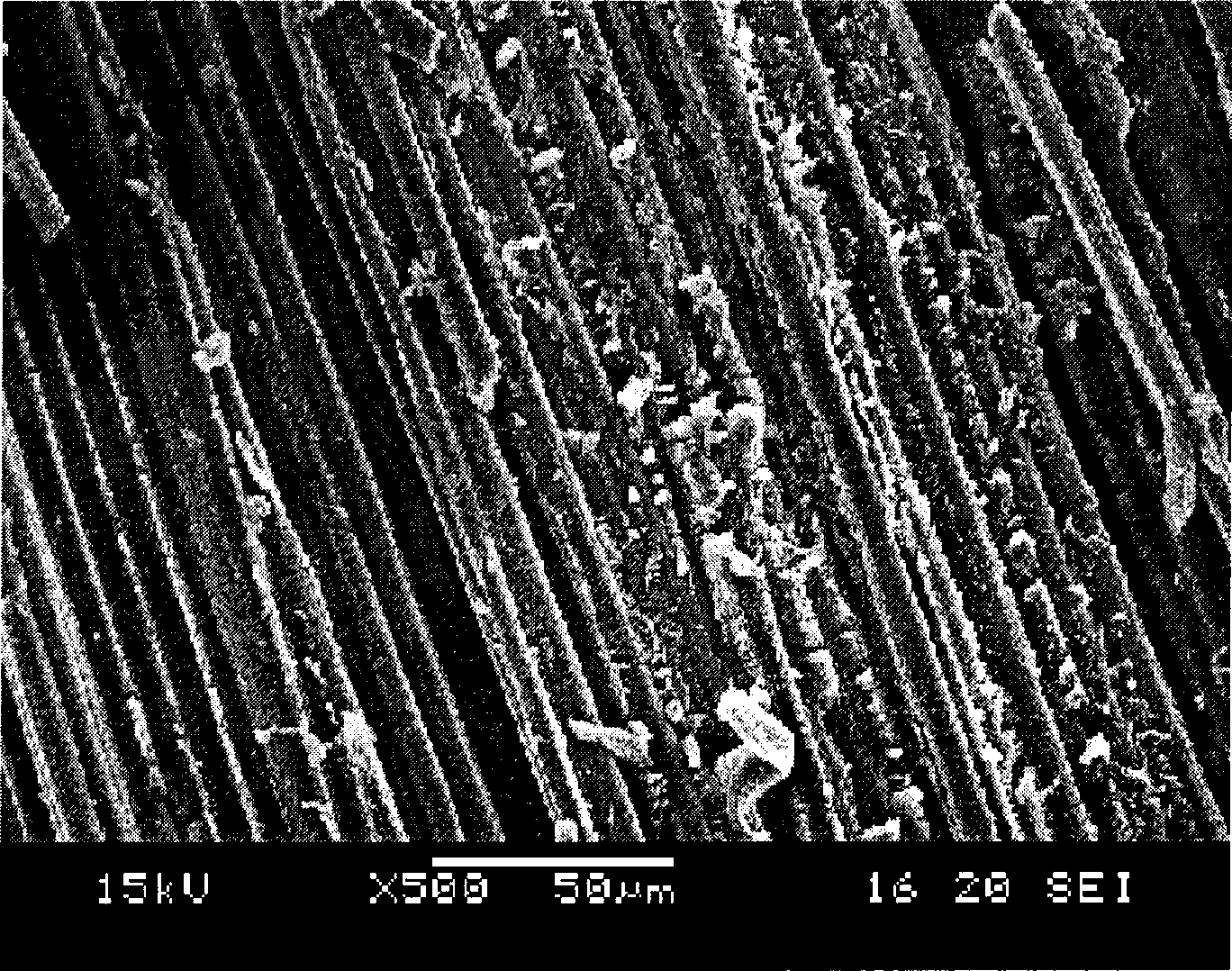

[0046] Vinyl ester resin (100 parts), low-temperature initiator (1.5 parts), high-temperature initiator (1.5 parts), and release agent (1 part) were mixed uniformly with a low-speed stirrer. In addition, the dried and dehydrated ZrC (18 parts) with a particle size of 40 nm was infiltrated with a coupling agent (3 parts) under stirring, and then treated with ultrasonic dispersion for 40 minutes to obtain a mixed solution. The 8K carbon fiber yarn is drawn into a mold with a diameter of 0.70mm by needle and thread, and dipped in glue. Start the air compressor and rod drawing machine, adjust the three-stage heating temperature (the first temperature zone is 70±5°C, the second temperature zone is 110±5°C, the third temperature zone is 135±5°C), and select the appropriate traction speed for continuous Stable pultruded carbon fiber rod. The obtained carbon fiber rods have an average diameter of 0.75 mm. After testing, the carbon fiber content is 67%, and the Zr content is 5.0%. R...

Embodiment 2

[0048] Unsaturated polyester resin (100 parts), high temperature curing agent (1 part), high temperature initiator (1 part), medium temperature initiator (1 part), low temperature initiator (0.7 part), mold release agent (3 parts) , low shrinkage agent (15 parts), mix well with a low-speed mixer. In addition, in the stirring state, the ZrB with a particle size of 2.0 μm has been dried and dehydrated 2 (30 parts) soaked with coupling agent (2 parts), and then treated with an internal cutting emulsifier, controlling the speed at 3000-5000rpm, and the time is 20-30min, so that the mixture is uniformly stirred at a high speed until it meets the predetermined viscosity value. Stir During the process, the temperature of the glue solution was kept at 30°C±2°C. At the same time, the 24K carbon fiber yarn is drawn into a mold with a diameter of 1.2mm by needle and thread, and dipped in glue. Start the air compressor and rod drawing machine, adjust the three-stage heating temperature,...

Embodiment 3

[0050] Bisphenol A type epoxy resin (100 parts), curing agent (6 parts), accelerator (2 parts), toughening agent (12 parts), release agent (3 parts), diluent (5 parts), Mix well with mixer on low speed. In addition, soak the dried and dehydrated ZrC (7 parts) with a particle size of 40nm and HfC (7 parts) with a particle size of 1.2μm with a coupling agent (3 parts) in a stirring state, and first process it with an internal emulsifier , control the rotation speed at 4500rpm, and the time is 20min, so that the mixture is uniformly stirred at a high speed, and then it is treated with ultrasonic dispersion method for 20min to prepare the mixture, and the temperature of the constant temperature system of the dipping tank is set at 60±5°C. At the same time, the 66K carbon fiber yarn is drawn into a mold with a diameter of 2.0 mm by needle and thread, and dipped in glue. Start the air compressor and rod drawing machine, adjust the three-stage heating temperature (the first temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com