Flake diamond-reinforced metal matrix composite and preparation method

A diamond-reinforced and composite material technology, which is applied in the field of composite diamond material preparation, can solve the problems of loose two-phase interface, poor wettability between diamond rod and matrix metal, etc., and achieve high production efficiency and high flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A tungsten foil with a thickness of 0.05mm is selected as the metal substrate. First, the surface of the metal substrate is pre-treated according to step (1); and then the diamond film is deposited by hot wire CVD according to step (2). The deposition process parameters: the distance between the hot wire and the wire is 6mm , substrate temperature 800°C, filament temperature 2200°C, deposition pressure 3KPa, deposition time 40 hours, CH 4 / H 2The volume flow ratio is 1:99, and the thickness of the diamond film is 60 μm, that is, the diamond sheet is obtained; (3) a layer of metal Ni film is first sputtered on the surface of the cored diamond sheet by magnetron sputtering, the sputtering power is 150W, and the pressure is 0.4 Pa, substrate temperature 300°C, argon flow rate 20sccm, Ni film thickness 1.0 μm; then use chemical vapor deposition technology to deposit a layer of graphene film on the surface of Ni film, film thickness 0.34nm; then use electroplating technology...

Embodiment 2

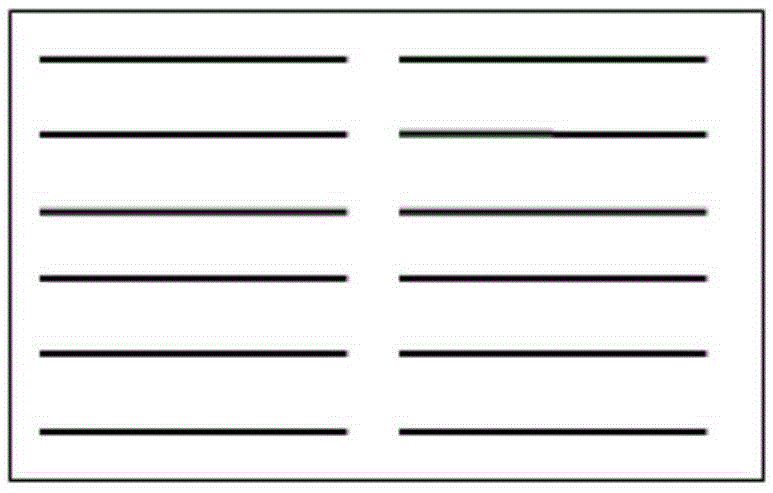

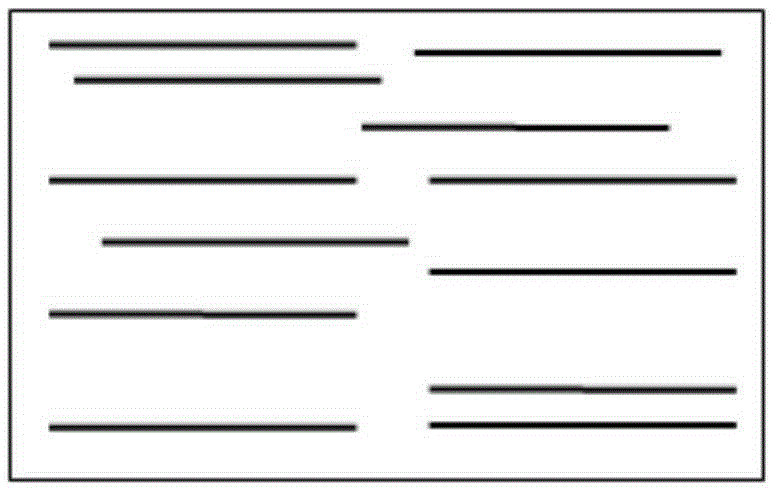

[0076] A copper foil with a thickness of 0.05mm is selected as the metal substrate, and it is rolled into a cylindrical shape with a diameter of 12mm, 10mm, and 8mm. Firstly, the surface of the metal substrate is pre-treated according to step (1); then, according to step (2), a diamond film is deposited on the inner and outer surfaces of each barrel-shaped metal substrate by hot-wire CVD deposition. The arrangement of the hot wire is shown in Figure 7. Show. Deposition process parameters: hot wire distance 6mm, substrate temperature 850°C, hot wire temperature 2200°C, deposition pressure 3KPa, deposition time 50 hours, CH4 / H2 volume flow ratio 1:99, to obtain a diamond film thickness of 100 μm, that is, a metal-lined (3) A layer of metal Cu film is sputtered on the inner and outer surfaces of the diamond sheet by magnetron sputtering, the sputtering power is 150W, the pressure is 0.4Pa, the substrate temperature is 300°C, the argon flow rate is 20sccm, and the Cu film thicknes...

Embodiment 3

[0078] Choose a silicon wafer with a thickness of 1.5mm as the sheet substrate, firstly carry out pre-treatment on the surface of the silicon substrate according to step (1); then follow step (2) to deposit a diamond film by hot wire CVD, deposition process parameters: hot wire distance 6mm, Substrate temperature 900°C, filament temperature 2300°C, deposition pressure 3KPa, deposition time 300 hours, CH 4 / H 2 The volume flow ratio is 3:97, and the thickness of the diamond film is 600 μm. After etching the sheet silicon substrate, the sheet-shaped self-supporting diamond is obtained; (3) a layer of metal Ni film is sputtered on the surface of the diamond sheet by magnetron sputtering method , the sputtering power is 200W, the pressure is 0.3Pa, the substrate temperature is 350°C, the argon gas flow rate is 50sccm, and the thickness of the Ni film is 0.5μm; the graphene film is prepared on the surface of the Ni film by chemical vapor deposition technology, and the thickness is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com