Inert matrix dispersion fuel pellet and preparation method thereof

A technology for dispersing fuel and matrix, applied in the fields of reactor fuel material, manufacturing reactor, climate sustainability, etc., can solve the problems of high sintering temperature, difficulty in lifting and pressing green body, etc., to improve comprehensive performance, increase volume content, The effect of reducing density differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

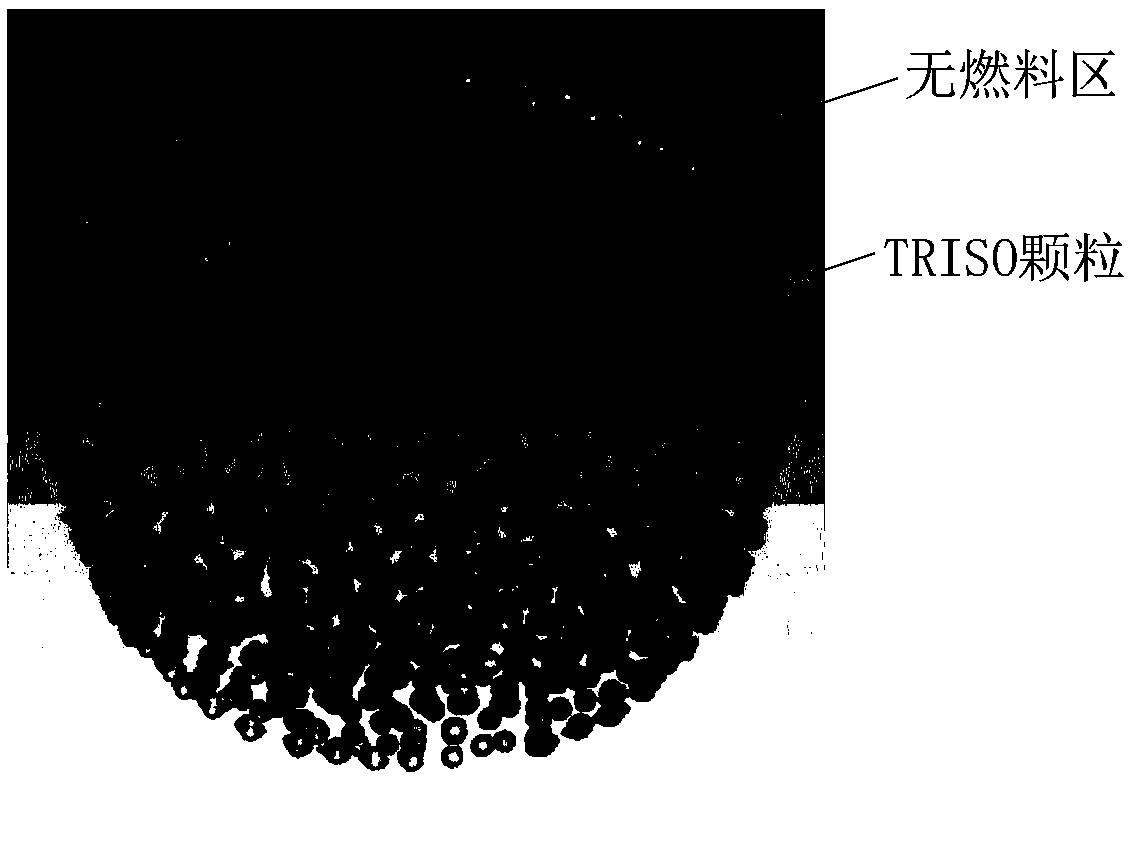

[0050] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

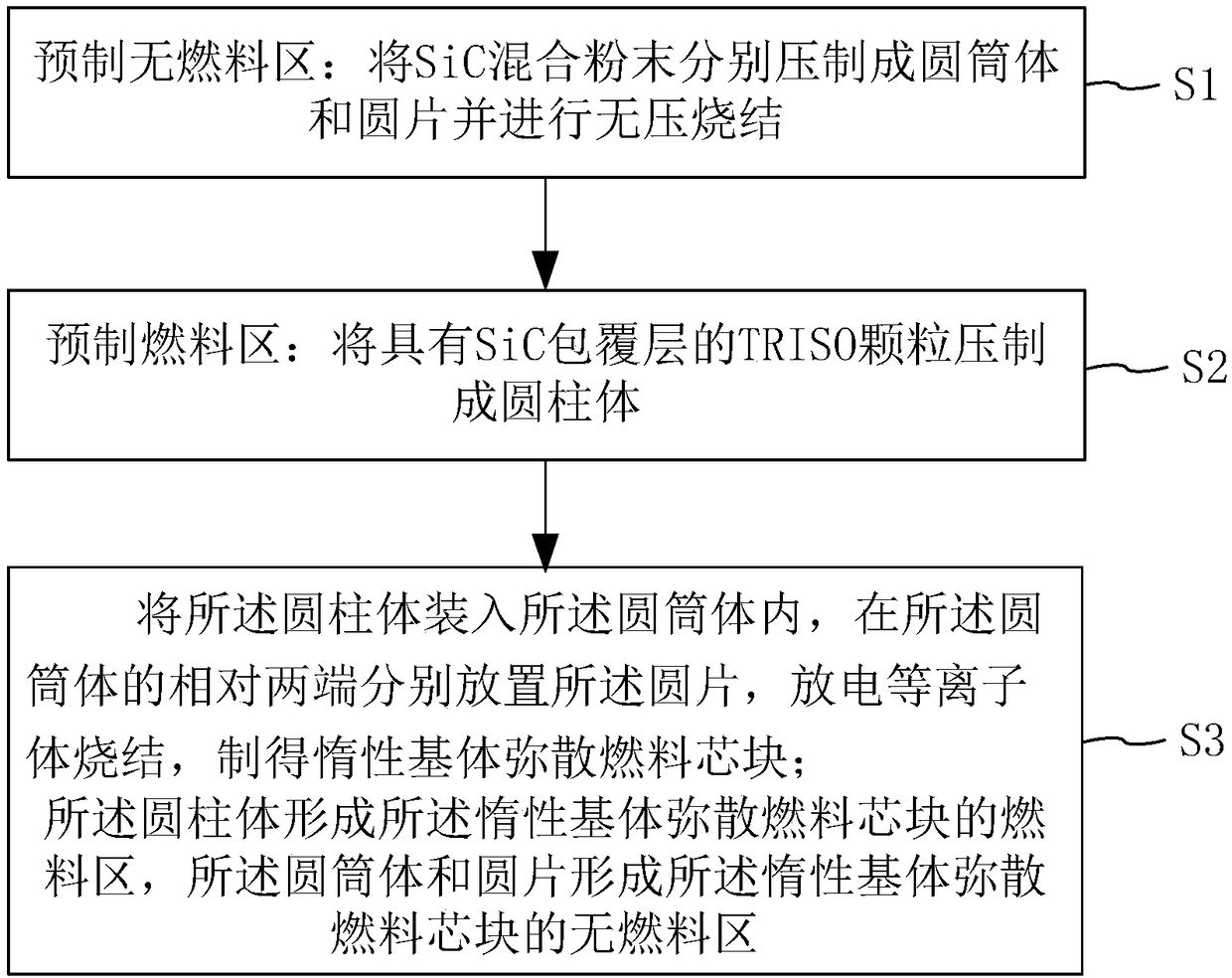

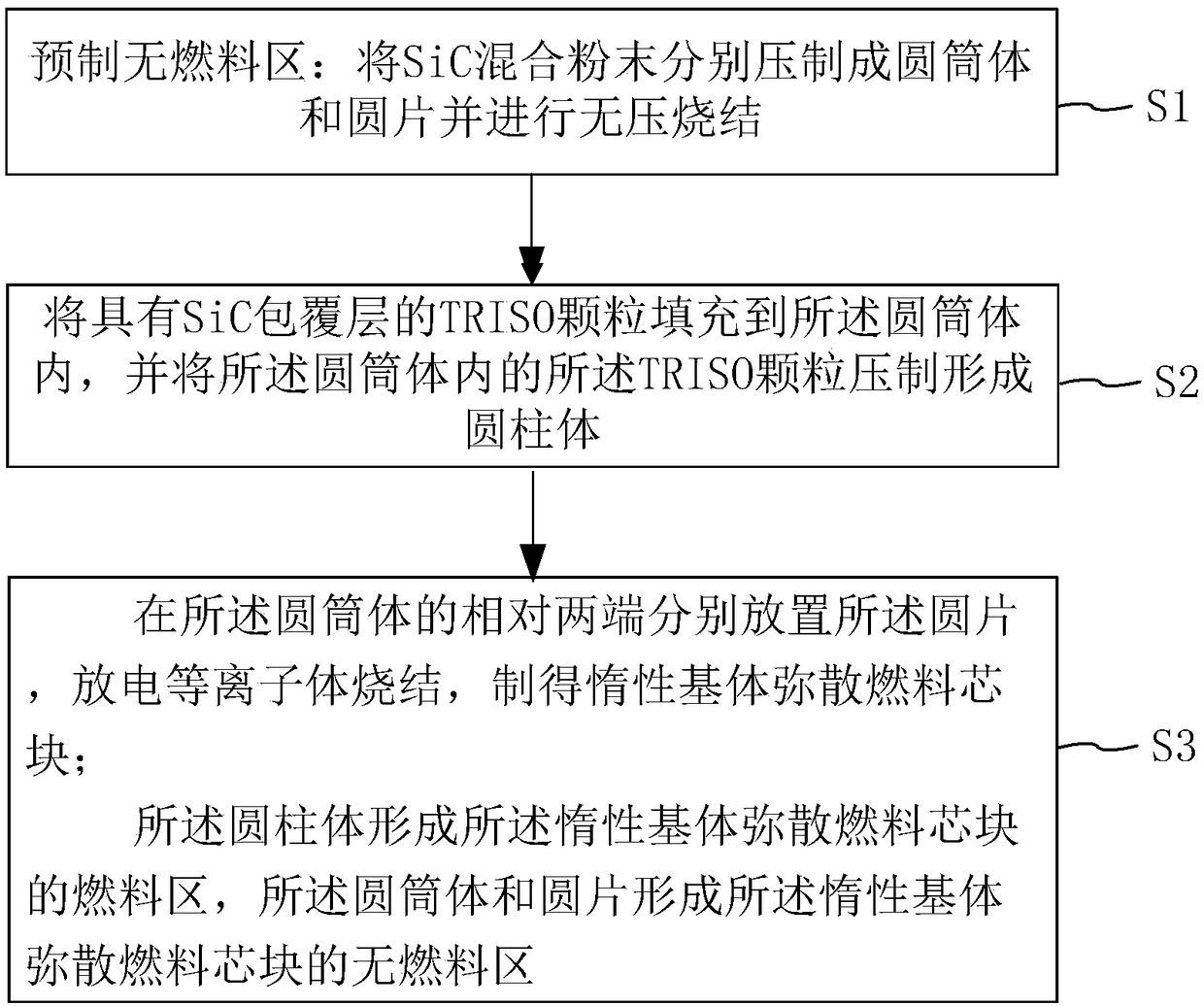

[0051] Such as figure 1 As shown, the preparation method of the inert matrix dispersed fuel pellets according to the first embodiment of the present invention may include the following steps:

[0052] S0, mixing the sintering aid, SiC powder, and dispersant in a predetermined ratio to obtain a uniformly dispersed SiC mixed slurry.

[0053] The prepared SiC mixed slurry is used as the raw material for the subsequent fuel-free zone and fuel zone.

[0054] S1. Prefabricated fuel-free zone: the SiC mixed powder is pressed into a cylinder and a disc respectively and subjected to pressureless sintering.

[0055] Step S1 may further include:

[0056]S1.1. Dry the SiC mixed slurry prepared in step S0 to form SiC mixed powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com