Symmetrical layered sample pressing device and sample preparation method for triaxial test sample preparation

A sample preparation and triaxial test technology, applied in the field of symmetrical layered sample pressing device, can solve the problems of sample disturbance, large deviation of test data, and long time consumption, so as to reduce the interference of friction force and improve the efficiency of sample preparation High and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

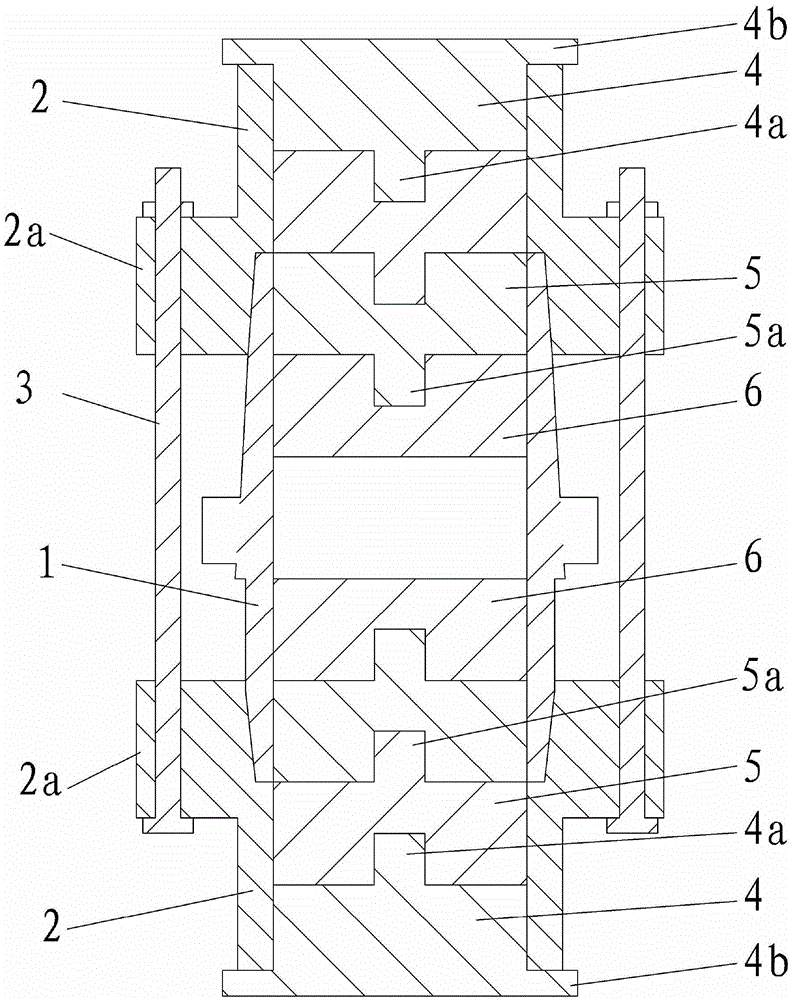

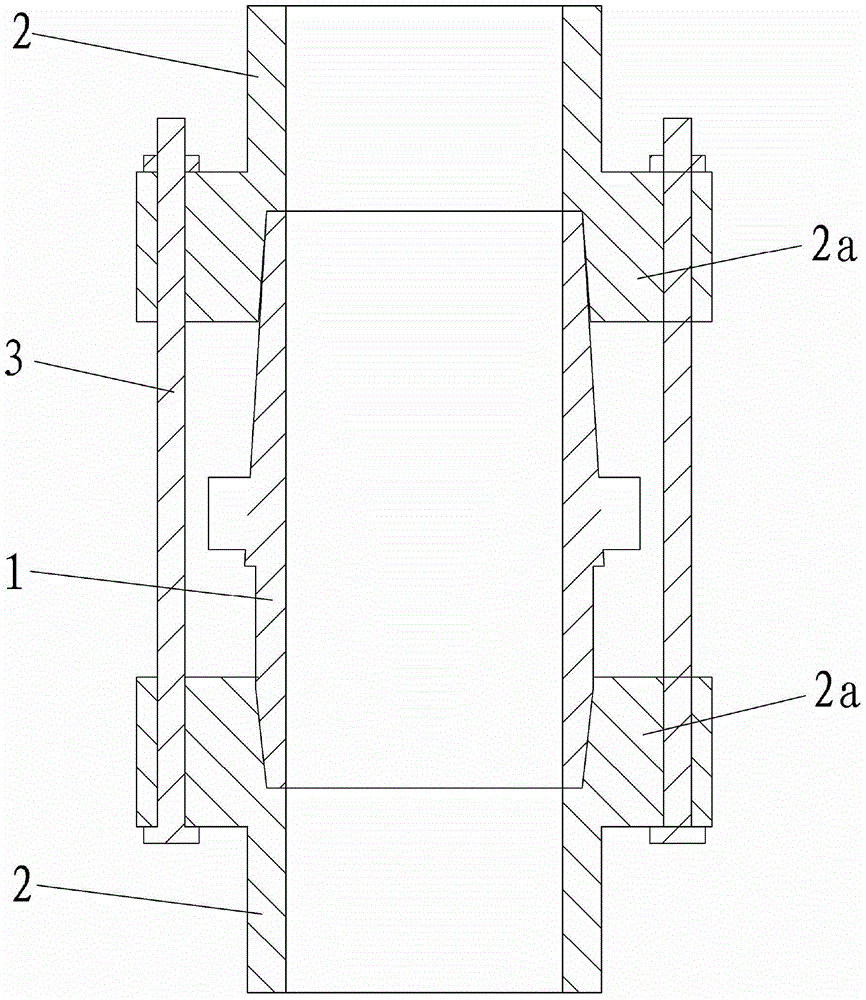

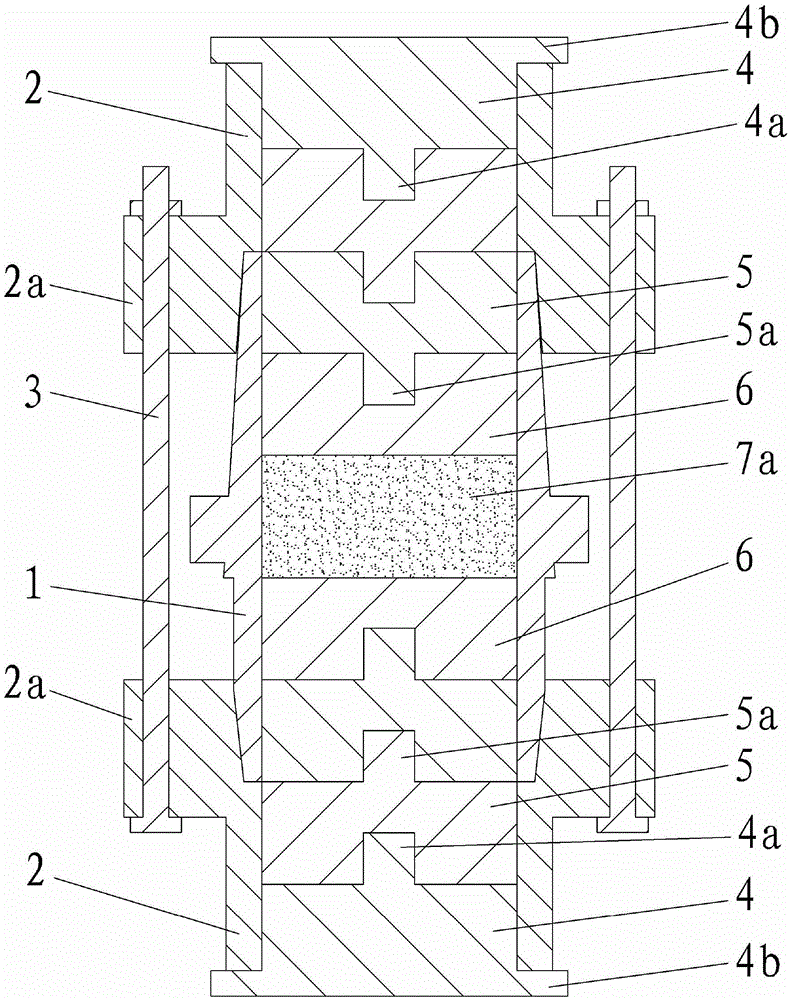

[0035] figure 1 , 2 It is shown that the specific embodiment of the present invention is a symmetrical layered sample pressing device for triaxial test sample preparation, wherein:

[0036] The outer walls of both ends of the cylindrical soil sample tube 1 fit into the slots on the inner wall of the extension tube 2, and the outer peripheral surface of the slot part of the extension tube 2 protrudes outward to form a flange 2a. The diameter of the inner wall is equal to the diameter of the inner wall of the soil sample cylinder; the flanges 2a of the extension cylinder 2 at both ends of the soil sample cylinder 1 are connected by a screw 3;

[0037] The extension tube 2 and the soil sample tube 1 are covered with a pad set, and the pad set is composed of:

[0038] The outer peripheral surface of the back end of the outer pad 4 protrudes outward to form a cover edge 4b, and the front center of the outer pad 4 is provided with a threaded protrusion 4a; the back center of the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com