Traction transmission belt and preparation method thereof

A traction drive, belt technology, applied in the direction of transmission belt, belt/chain/gear, belt, etc., can solve the problems of steel cable metal material fatigue, increase the weight of the transmission system, increase the length of the steel cable, etc., to save operating costs, excellent resistance Creep performance, low cost effect

Active Publication Date: 2011-03-02

NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

View PDF7 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the common problem of this kind of traction transmission steel cable is: when the floor is high, the length of the required steel cable increases; when the load-bearing mass is large, thicker steel cables are required or the number of steel cables is increased to achieve safe transmission. , so, the weight of the transmission system will be greatly increased in the end, which will increase energy consumption accordingly and is not conducive to environmental protection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

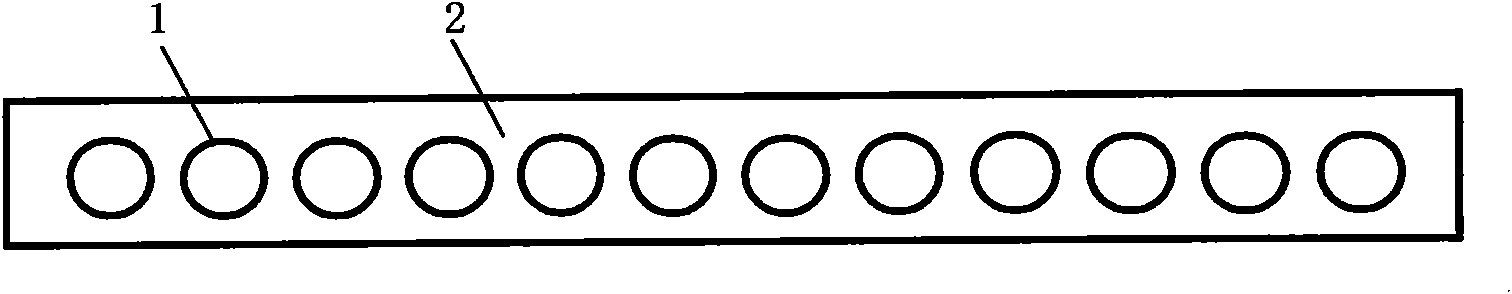

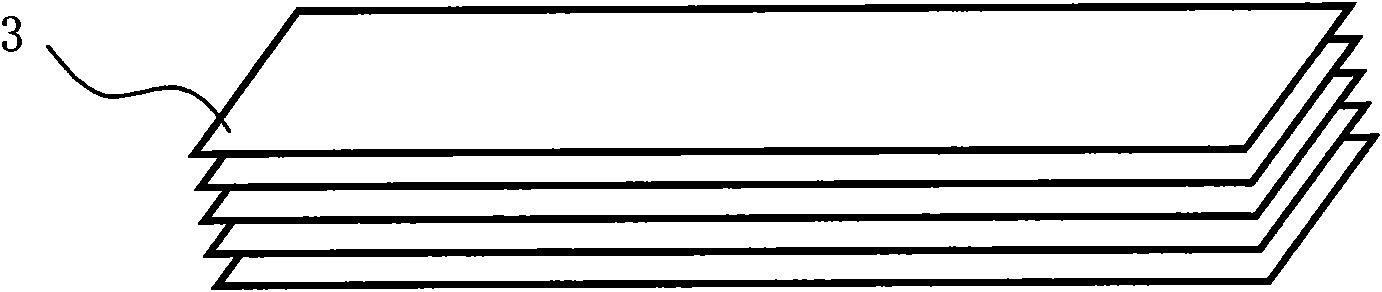

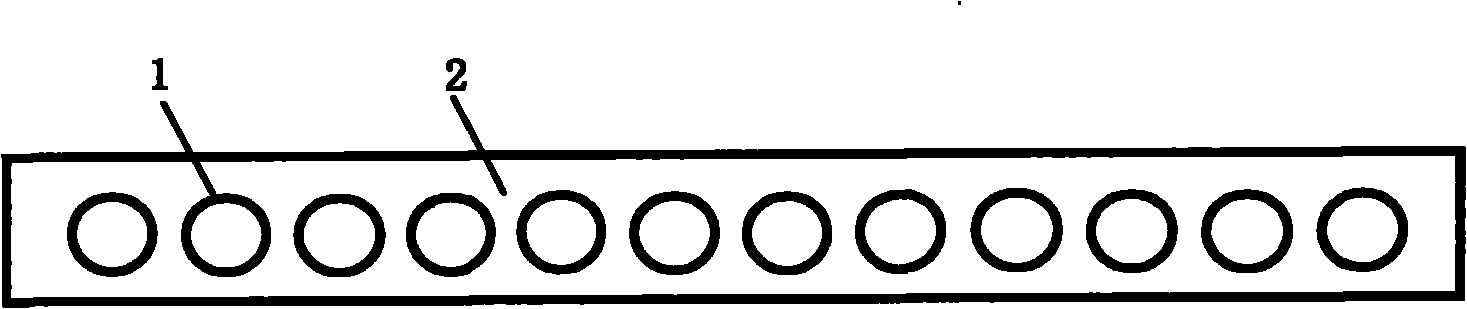

The invention discloses a method for preparing a traction drive belt which comprises the following steps: firstly obtaining carbon fiber composite slender rods with diameter of 0.5-5mm after molding and curing carbon fiber beams which are doped with a resin adhesive solution under the action of attraction through a pultrusion mold; then arranging a plurality of carbon fiber composite slender rods in parallel along a length direction of a belt base, introducing into a belt building machine and recombining with elastic materials forming the belt base, forming a traction drive belt; finally performing a post-treatment according the use of the traction drive belt. Compared with the prior art, the preparation method of the invention has low cost, can satisfy the industry actual demand with continuous production. The characteristics of light weight, favorable toughness, corrosion resistance, fatigue resistance, favorable mechanical properties and the like of the carbon fibers are given full play, so that the prepared traction drive belt has the advantages of light dead weight and high operating efficiency, thereby lowering the energy consumption and saving the operating cost.

Description

technical field [0001] The invention relates to the technical field of traction transmission belts, in particular to a traction transmission belt and a preparation method thereof. Background technique [0002] At present, the traction transmission belt generally adopts twisted steel wire rope, that is, the steel cable as the main load-bearing component, such as the traction transmission component used for the up and down movement of the elevator. However, the common problem of this kind of traction transmission steel cable is: when the floor is high, the length of the steel cable required increases; when the load-bearing mass is large, thicker steel cables or the number of steel cables are required to achieve safe transmission. , Therefore, the dead weight of the transmission system will be greatly increased in the end, which will increase energy consumption accordingly and is not conducive to environmental protection. In addition, the bending radius of the steel wire rope ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16G1/21F16G1/16F16G1/08B29D29/06

CPCD07B1/22D07B7/145D07B2205/3007D07B2501/2007D07B2801/10

Inventor 范欣愉

Owner NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com