Carbon fiber composite material bone fracture plate and preparation method thereof

A technology of composite materials and composite material layers, which is applied in the direction of chemical instruments and methods, outer plates, phosphorus compounds, etc., can solve problems such as large differences in thermal expansion coefficients, poor mechanical properties, and weak connection strength, so as to improve bonding strength and improve Comprehensive mechanical properties, the effect of avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

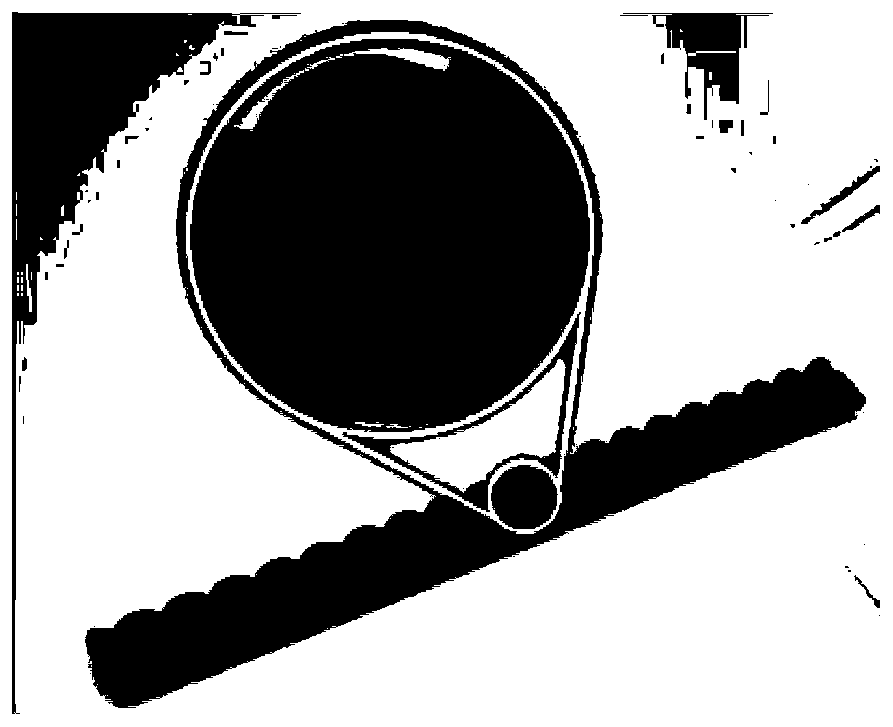

[0045] 1) First twist 4 bundles of 3k carbon fibers into a carbon fiber rope with a twist of 180 twists / m; then weave 12 twisted carbon fiber ropes into a strip-shaped continuous fiber braid.

[0046] 2) Using needles to make the area density 30g / m 2 The carbon fiber nonwoven fabric is riveted on the continuous fiber braid, and the riveting density is 12 points / cm 2 , to obtain a carbon fiber preform.

[0047] 3) The carbon fiber prefabricated body is placed in a vacuum furnace. At a temperature of 1150 ° C, the gas source (trichloromethylsilane, hydrogen as the carrier gas and dilution gas) is introduced, and the flow ratio of trichloromethylsilane to hydrogen is 1: 5) After pyrolysis, the chemical vapor phase is infiltrated into the carbon fiber blank, and after 50 hours, a carbon fiber composite material blank is prepared.

[0048] 4) Electrochemical deposition is used to generate hydroxyapatite on the green body treated in 3), and part of hydroxyapatite penetrates into t...

Embodiment 2

[0052] 1) First twist 3 bundles of 1k carbon fibers into a carbon fiber rope with a twist of 320 twists / m; then weave 15 twisted carbon fiber ropes into a strip-shaped continuous fiber braid.

[0053] 2) Using needles to make the area density 40g / m 2 The carbon fiber non-woven fabric is riveted on both sides of the continuous fiber braid to form a sandwich structure, and the riveting density is 10 points / cm 2 , to obtain a carbon fiber preform.

[0054] 3) The carbon fiber preform undergoes densification processes such as silicon-containing precursor (PCS) vacuum pressure impregnation, curing treatment, and cracking. The impregnation pressure is 2.0MPa, the impregnation time is 5 hours; the curing temperature is 180°C, the curing time is 30 hours, the cracking temperature is 1000°C, the time is 5 hours; the ceramicization temperature is 1400°C, the time is 5 hours, and the carbon fiber is prepared Composite body.

[0055] 4) Plasma spraying is used to generate hydroxyapatit...

Embodiment 3

[0059] 1) First twist 2 bundles of 6k carbon fibers into a carbon fiber rope with a twist of 250 twists / m; then weave 24 twisted carbon fiber ropes into a strip-shaped continuous fiber braid.

[0060] 2) Using needles to make the area density 40g / m 2 The carbon fiber non-woven fabric is riveted on both sides of the continuous fiber braid to form a sandwich structure, and the riveting density is 10 points / cm 2 , to obtain a carbon fiber preform.

[0061] 3) The carbon fiber prefabricated body first generates silicon carbide through liquid impregnation-cracking, and then deposits the carbon matrix through vapor phase. Deposition of silicon carbide process: After vacuum pressure impregnation of silicon-containing precursor (PMS), curing treatment, cracking and other densification processes. The impregnation pressure is 1.0MPa, the impregnation time is 3 hours; the curing temperature is 220°C, the curing time is 10 hours, the cracking temperature is 1000°C, the time is 5 hours; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com